Array type ultrasonic paper thickness measurement device

A technology of thickness measurement and ultrasonic, which is applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic, instruments, etc., can solve problems such as uneven thickness and measurement errors, and achieve improved measurement accuracy, interchangeability, and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

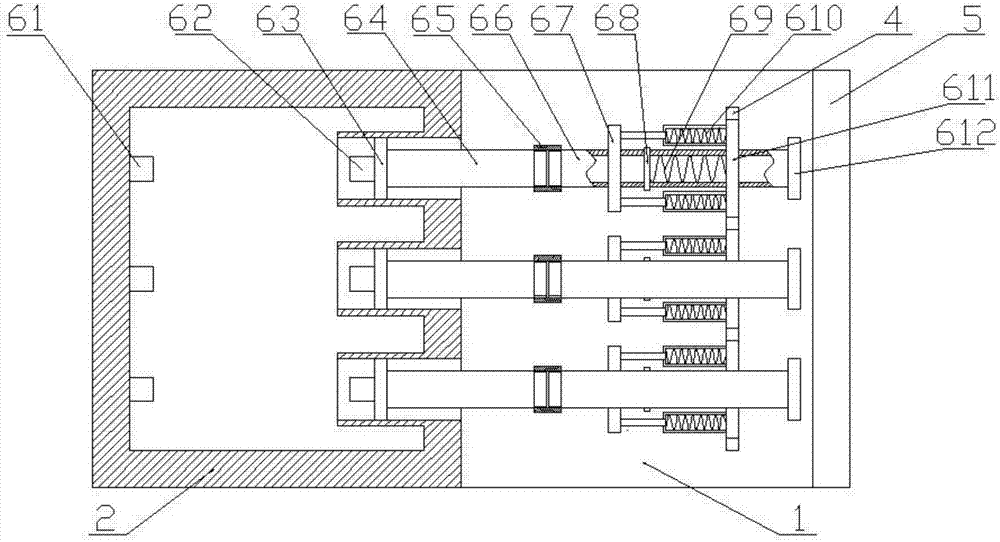

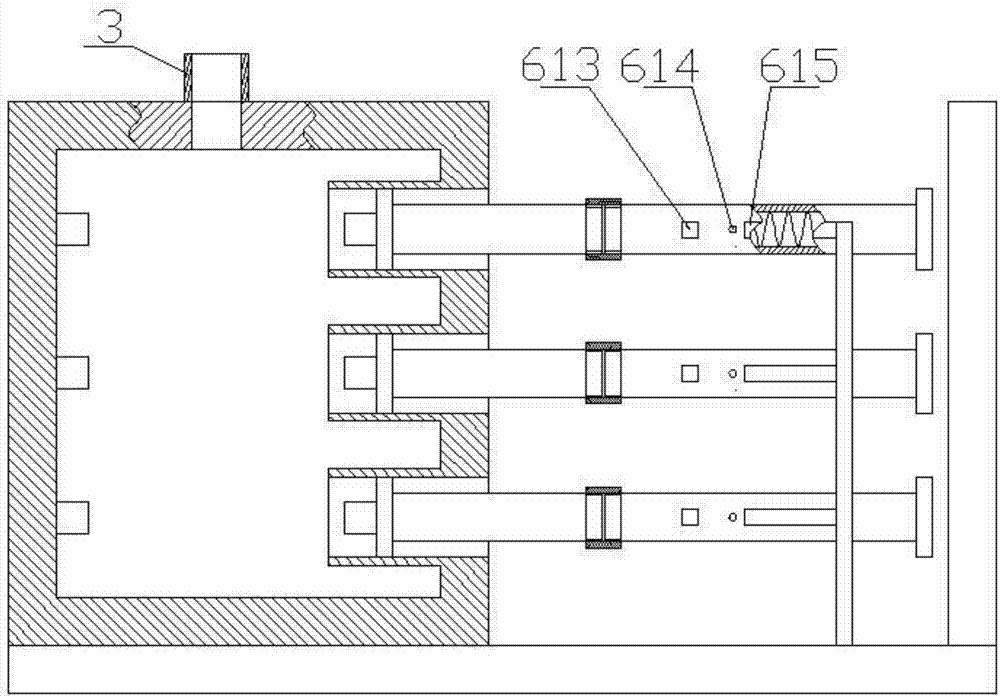

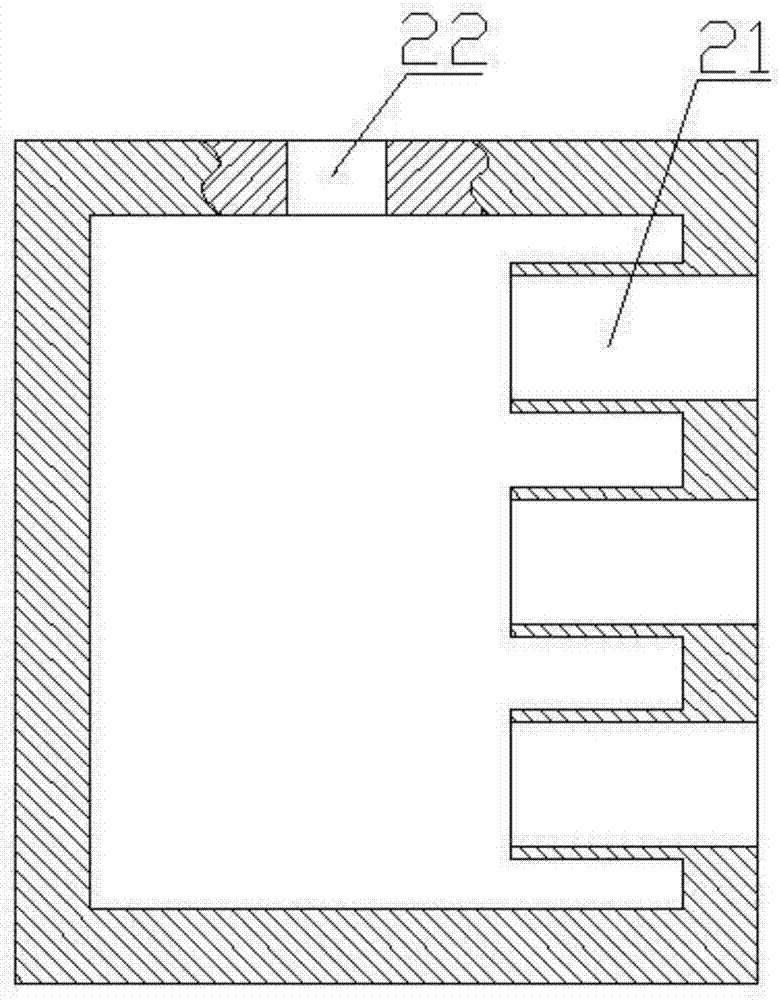

[0022] The invention provides an array type ultrasonic paper thickness measuring device (see Figure 1-4 , referred to as the device), is characterized in that the device includes a base 1, a tank body 2, an air pipe 3, a bracket 4, a paper surface 5 and N 2 Measuring mechanisms, N is a positive integer greater than or equal to 2; each of the measuring mechanisms has the same structure, arranged in a rectangular array after installation, the number of rows and columns in the array is N, each horizontally or vertically adjacent The distance between the measuring mechanisms is the same; in the present embodiment, N=3; each measuring mechanism includes an ultrasonic transmitting probe 61, an ultrasonic receiving probe 62, a piston 63, a left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com