Method for realizing three-dimensional color jet printing of embossed board

A technology of embossed board and spray printing, which is applied in the field of embossed board three-dimensional color jet printing equipment and its spray printing, which can solve the problem of not being able to meet the needs of users in pursuit of personalized design or diverse design, and cannot guarantee the coating color and coating effect Consistency, affecting production efficiency and production scale and other issues, to achieve the effect of simple structure, low cost, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific examples.

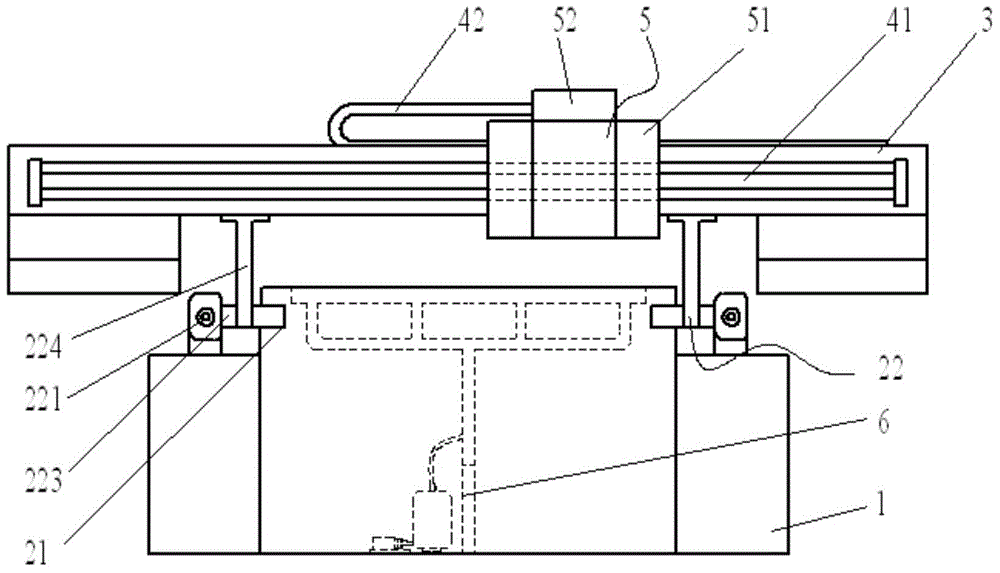

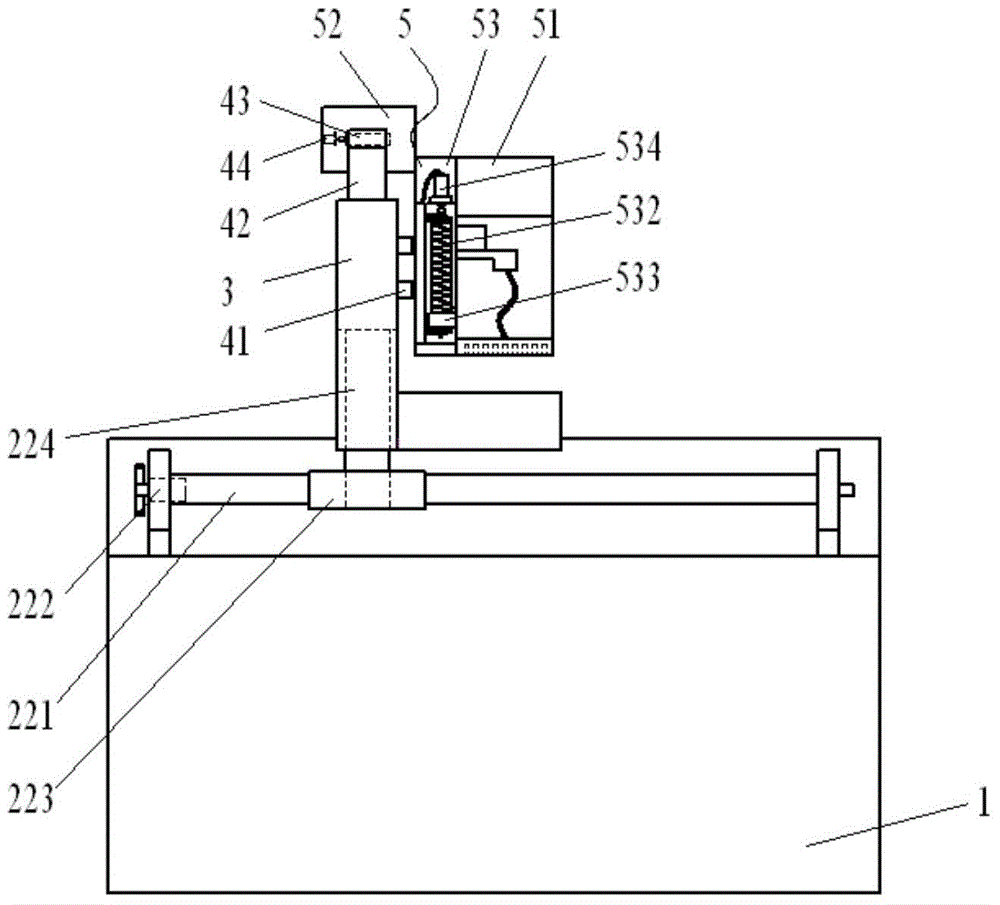

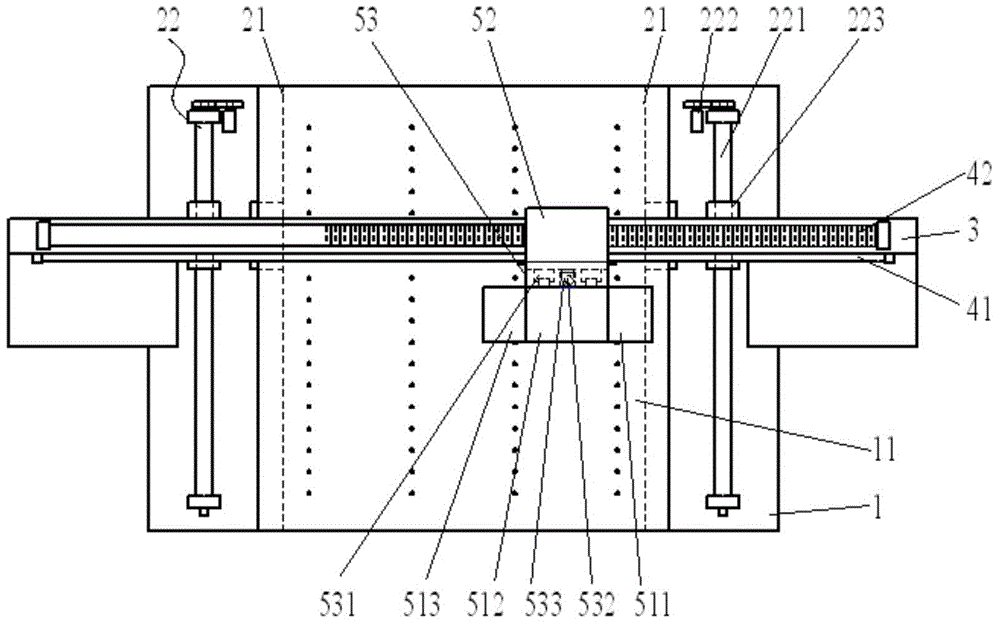

[0035] Such as figure 1 , 2 . As shown in 3, a three-dimensional color jet printing equipment for embossed boards, comprising: a jet printing platform 11 of the base 1 of the jet printing equipment, on which the embossed board to be printed is placed; The point to be printed on the embossed plate to be printed on the platform 11 is used to adjust the position of the printing assembly 51 in the X, Y, and Z directions, so that the printing assembly 51 moves to the point to be printed on the embossed plate to be printed. Directly above the position; the printing assembly 51 is used for printing the dots to be printed on the embossed board to be printed according to the printing pattern information from the computer until the printing of all the dots to be printed on the embossed board to be printed is completed. Printing; the adsorption system arranged under the printing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com