Fixing element and fixing frame for electric control equipment of low-floor vehicle

A technology of electronic control equipment and fixing parts, which is applied in the direction of railway car body parts, locomotives, transportation and packaging, etc., can solve the problems of many electronic control devices, occupying the space of the driver's cab, and inconvenient installation of cabinets, so as to solve the problems of large quantity, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

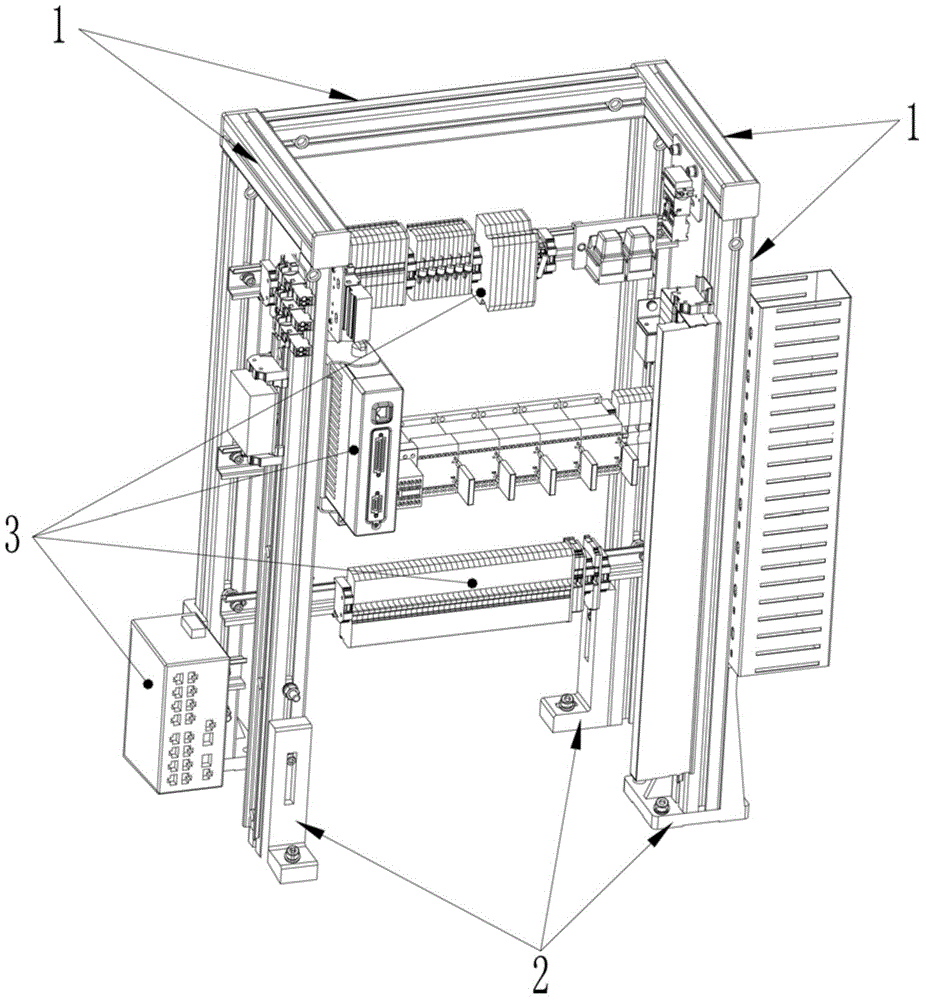

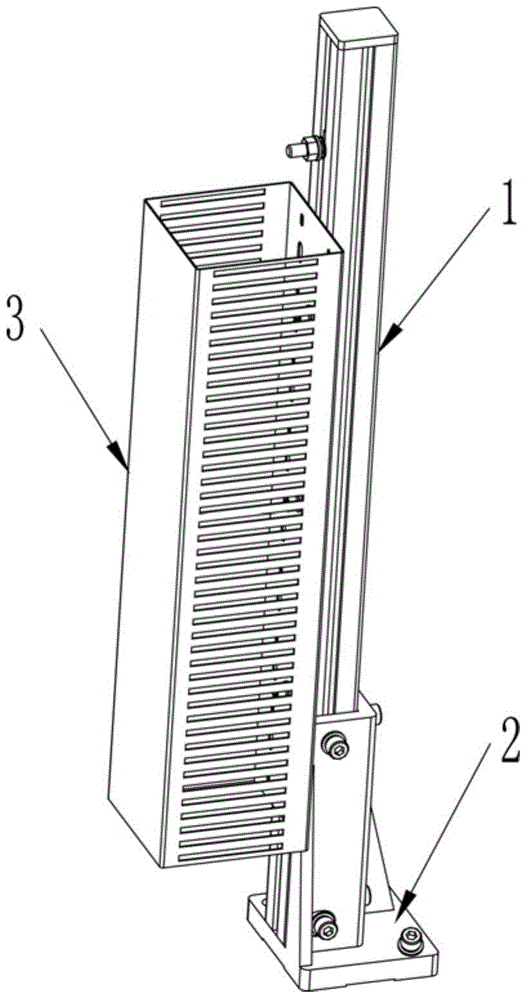

[0029] 1. The installation hole of the electronic control device 3 is directly connected with the chute 12 on the cross bar or column through the connecting bolt;

[0030] 2. Install the electronic control device 3 on the installation board, and then connect the installation board with the column or the cross bar;

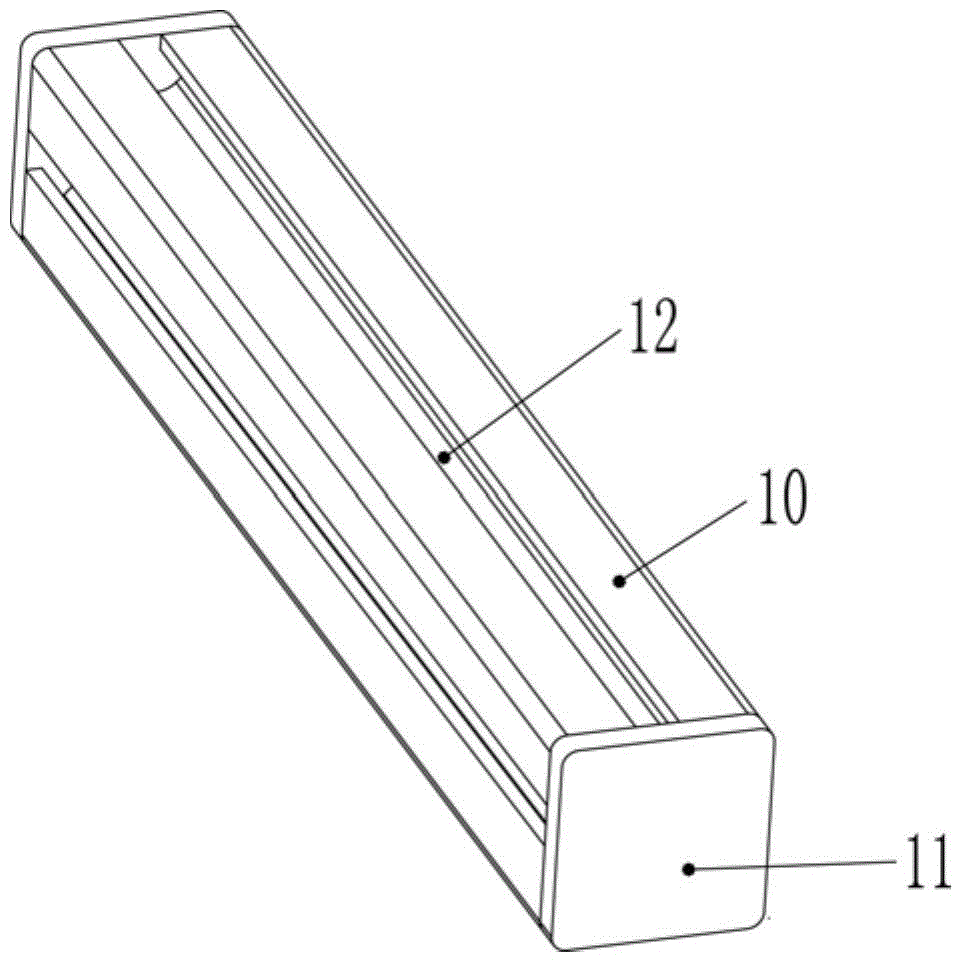

[0031] 3. Connect a guide rail 4 between two parallel columns or cross bars, and the electronic control device 3 is slidably clamped on the guide rail 4; At least one oblong hole is set, and the length direction of the oblong hole is consistent with the length direction of the guide rail 4, and the guide rail 4 is connected with the connecting bolt on the fixing part 1 through the oblong hole (such as Figure 5 ). The position of the guide rail 4 can also be adjusted by loosening the connecting bolts.

[0032] It can be seen from the above embodiments that if there are fewer electronic control devices 3 to be installed in the cab, only one fixing piece 1 can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com