Door lock tool frame

A tool rack and door lock technology, which is applied in the direction of preventing mechanical damage, packaging of vulnerable items, containers, etc., can solve problems such as elevator safety hazards, door lock quality problems, etc., to avoid quality problems, not easy to collide, and easy to turn around safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

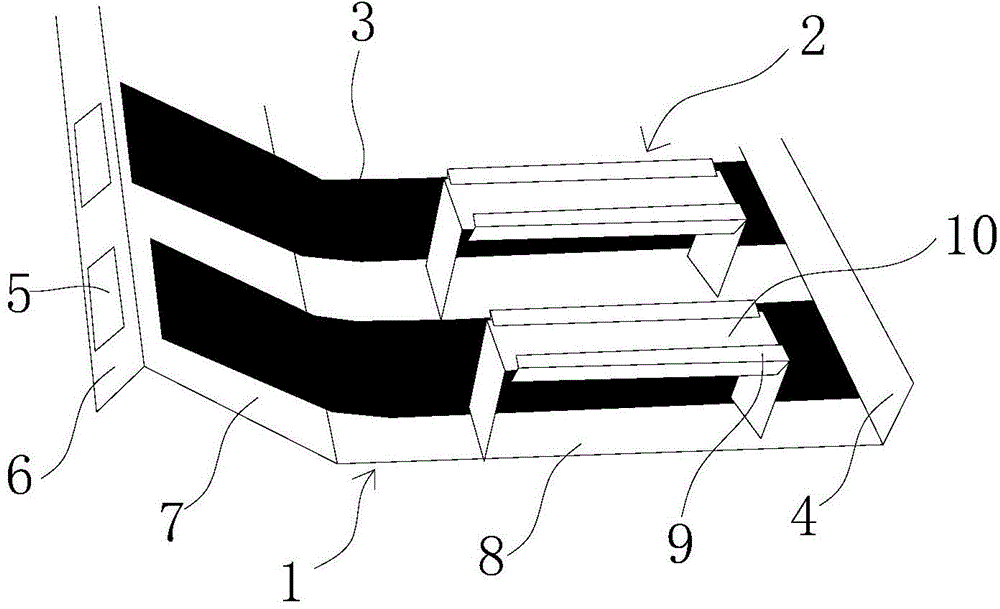

[0018] Such as figure 1 As shown, the door lock tool rack includes a bottom support plate 1, a separation bracket 2 evenly arranged on the bottom support plate 1, and a rectangular buffer pad 3 arranged in the middle of the separation support 2;

[0019] The bottom support plate 1 includes an outer edge portion 6, a holding portion 7, a bottom plate portion 8 and a partition portion 4;

[0020] The separation bracket 2 is evenly welded on the bottom plate portion 8 in turn, and the two sides of the top platform 10 of the separation bracket 2 are also provided with anti-collision pads 9;

[0021] The width of the bottom support plate 1 is smaller than the length of the elevator door lock, and the spacing of the separating brackets 2 is slightly larger than the thickness of the elevator door lock.

[0022] A digital label 5 is provided at a position corresponding to the outer edge portion 6 and the cache pad.

[0023] A pair of the bottom support plate 1 , the separation brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com