Rotary braking system and tower crane control system

A technology of slewing braking and control system, applied in the field of frequency conversion control, can solve problems such as accidents, loss of control of slewing mechanism, failure of eddy current coil power failure, etc., and achieve the effect of preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

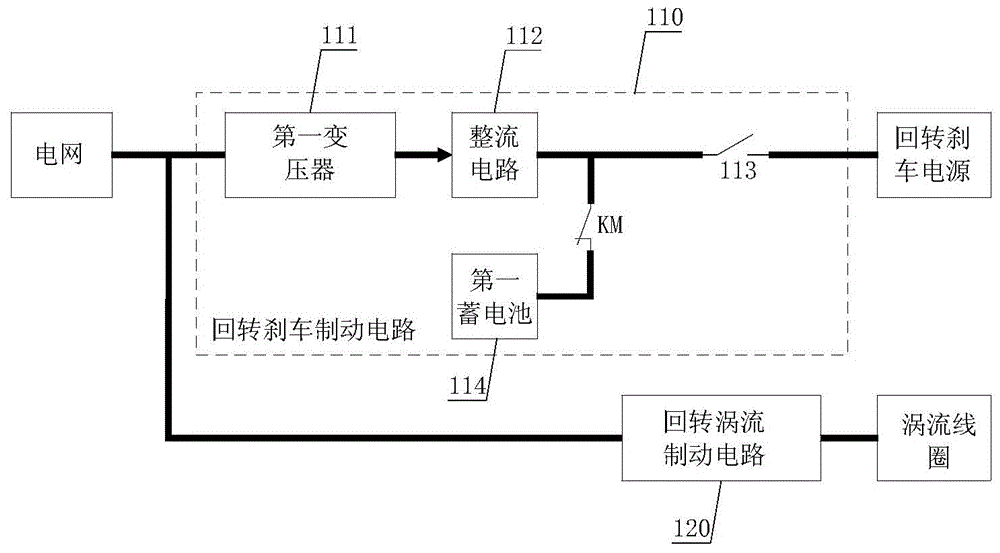

[0034] see Figure 1a-1b , Embodiment 1 of the present invention discloses a slewing braking system to prevent eddy current braking failure and out-of-control risks caused by grid power outages or failures (such as grid phase loss or instantaneous power failure, etc.), including slewing Brake brake circuit 110 and rotary eddy current brake circuit 120;

[0035] The slewing brake braking circuit 110 includes: a switch KM that is automatically closed when the power grid suddenly loses power or fails, a first transformer 111, a rectifier circuit 112 and a brake switch 113 connected in series between the power grid and the slewing brake power supply of the tower crane, and connected to the first storage battery 114 of the slewing brake power supply via the switch KM and the brake switch 113;

[0036] Among them, the switch KM can be automatically controlled by the electric control part of the tower crane. The switch KM is preferably the total contactor KM of the tower crane. self...

Embodiment 2

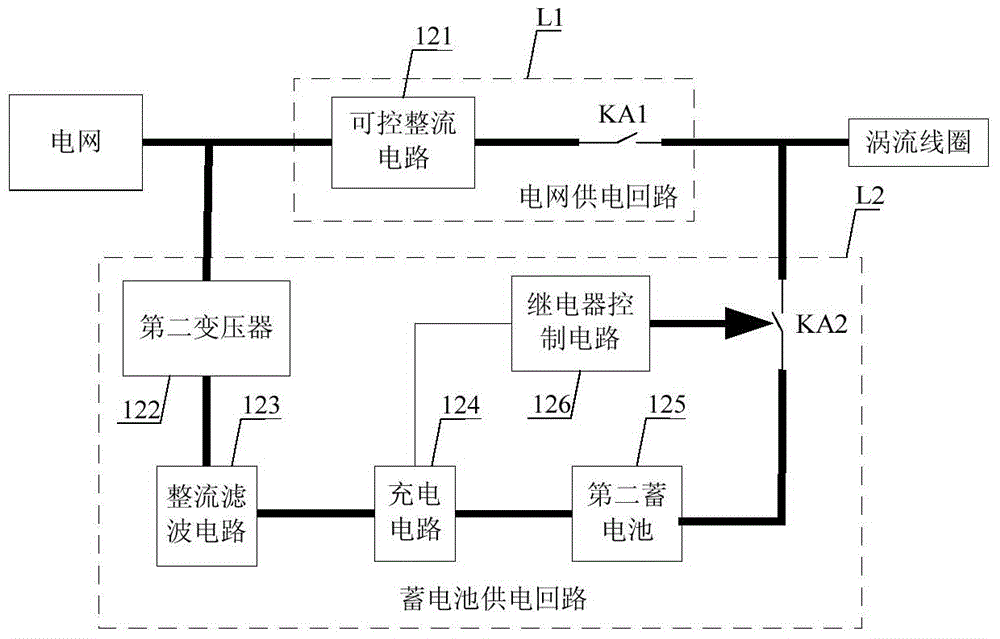

[0075] see figure 2 , Embodiment 2 of the present invention discloses another rotary braking system to prevent the risk of eddy current braking failure and loss of control caused by power failure or failure of the grid, including a rotary braking circuit 110 and a rotary eddy current braking circuit 120 ;

[0076] The slewing brake circuit 110 includes: a first controllable rectifier circuit 111 and a brake switch 112 connected in series between the grid and the slewing brake power supply of the tower crane;

[0077] The rotary eddy current braking circuit 120 includes a grid power supply circuit L1 and a battery power supply circuit L2, wherein:

[0078] The grid power supply circuit L1 includes a second controllable rectifier circuit 121 and an external control relay KA1 connected in series between the grid and the eddy current coil of the eddy current motor, but not limited thereto;

[0079] The storage battery power supply circuit L2 includes a transformer 122 connected...

Embodiment 3

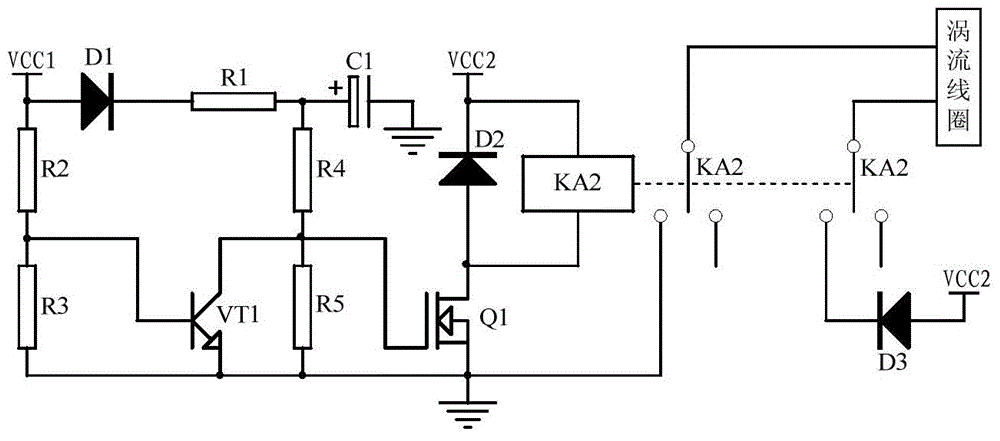

[0083] see image 3 , Embodiment 3 of the present invention discloses a tower crane control system to prevent the risk of eddy current braking failure and loss of control caused by power outage or failure of the power grid, including an eddy current motor M1, a frequency converter 10 for driving the eddy current motor M1, And a rotary braking system 20 for braking the eddy current motor M1; wherein, the rotary braking system 20 adopts the structure disclosed in the first embodiment.

[0084] The tower crane control system adopts frequency conversion drive and eddy current braking for the eddy current motor M1 to realize the slewing action of the boom. In terms of variable frequency drive, the operating signals (such as zero position, left turn, right turn, second gear, third gear, fourth gear) and fault reset signals sent by the master controller of the cab are connected to the switching value of the inverter 10. Input port, by monitoring the different states of the master co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com