Device and method for improving deep denitrification of internal carbon source denitrification by improving uct staged water inflow process

A segmented water inflow and deep denitrification technology, applied in chemical instruments and methods, multi-stage water treatment, aerobic and anaerobic process treatment, etc., can solve the problem of increasing the burden of sewage treatment costs, low levels of organic carbon sources, and environmental safety Threats and other issues, to achieve the effect of improving sludge settling performance, increasing total nitrogen removal rate, and reducing total emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

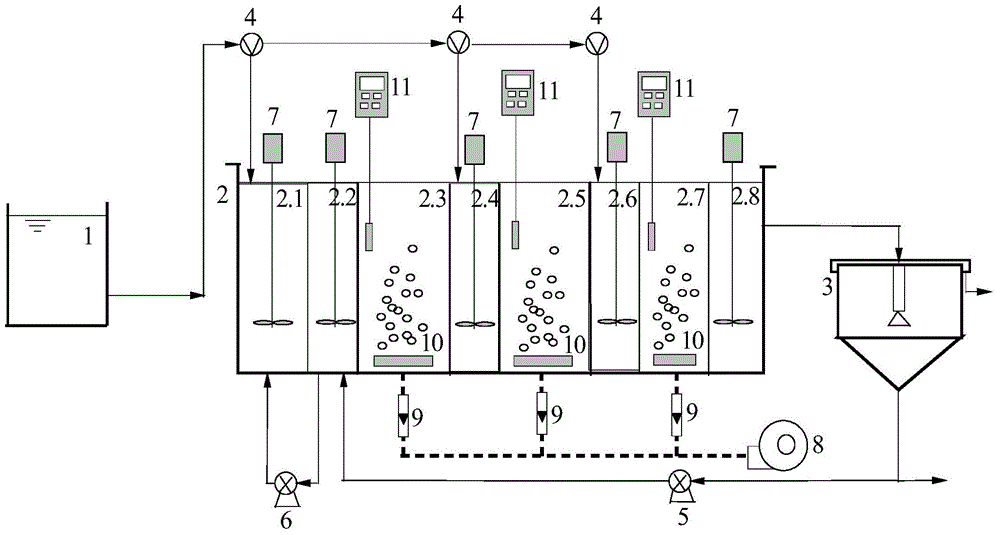

[0021] The present invention will be further explained below in conjunction with the drawings: figure 1 As shown, a device for strengthening internal carbon source denitrification based on UCT segmented water inflow process is characterized by:

[0022] Including water inlet tank 1, main reactor 2, sedimentation tank 3, water inlet pump 4, sludge return pump 5, internal return pump 6, stirrer 7, air pump 8, gas flow meter 9, etc. The inlet tank 1 is connected to the first anaerobic zone 2.1, the second anoxic zone 2.4, and the third anoxic zone 2.6 in the main reactor 2 through the inlet pump 4 and the inlet pipeline; The four-stage anoxic zone 2.8 is connected to the sedimentation tank 3 through a water pipe, and part of the sludge at the bottom of the sedimentation tank 3 flows back to the first-stage anoxic zone 2.2 through the sludge return pipeline and the sludge return pump 5, and the first-stage anoxic zone 2.2 Part of the sludge is returned to the first-stage anaerobic z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com