A coating type waterborne two-component fluorocarbon coating and its preparation and application

A fluorocarbon coating and coating technology, applied in polyurea/polyurethane coatings, coatings, photovoltaic power generation, etc., can solve problems such as high curing temperature, affecting system stability, and not conforming to PET materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] Preparation of waterborne two-component fluorocarbon coating

[0083] The present invention also provides a preparation method of water-based two-component fluorocarbon coating, comprising the steps of:

[0084] (1) Preparation of component A: first add deionized water according to the formula amount, slowly add anti-sedimentation agent under stirring, disperse until it becomes a uniform viscous slurry liquid, add wetting dispersant and defoamer and stir for 15 minutes , then add the pigment, disperse evenly, and grind it with a grinder until the fineness is less than 10 μm, filter to remove the grinding medium, add fluorocarbon emulsion, co-solvent, substrate wetting agent, leveling agent, catalyst and matting powder, and disperse evenly and finely If the viscosity is less than 30μm, add a thickener at the end, adjust the viscosity with deionized water, and then filter and package it as component A;

[0085] (2) Preparation of component B: mix and disperse HDI, IPDI (...

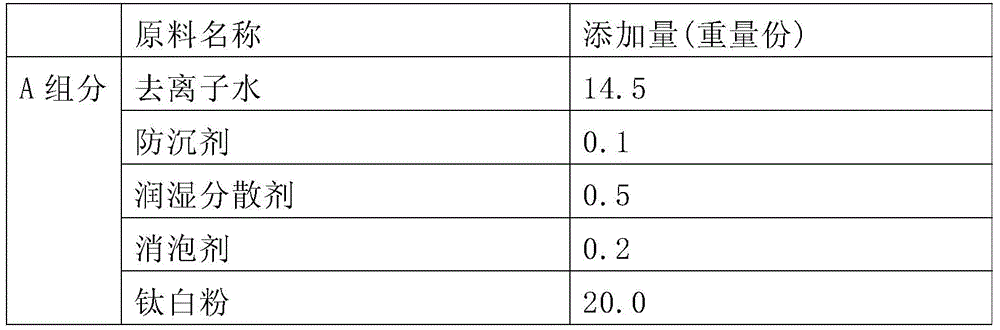

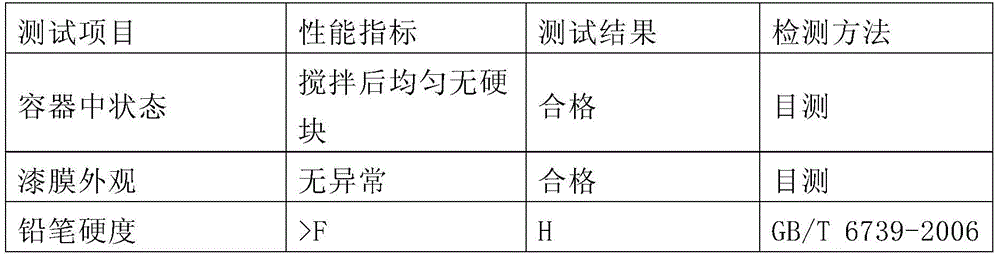

Embodiment 1

[0100]

[0101]

[0102] Described fluorocarbon emulsion is ETERFLON 4303 series products (made by Changxing Chemical Industry);

[0103] (1) Preparation of component A: first add deionized water according to the formula amount, slowly add anti-sedimentation agent under stirring, disperse until it becomes a uniform viscous slurry liquid, add wetting dispersant and defoamer and stir for 15 minutes , then add the pigment rutile titanium dioxide, disperse evenly, grind it with a grinder until the fineness is less than 10 μm, filter and remove the grinding medium, add fluorocarbon emulsion, co-solvent, substrate wetting agent, leveling agent, catalyst and matting powder, Disperse evenly and have a fineness of less than 30 μm. Finally, add a thickener, adjust the viscosity with deionized water, and filter and pack it to become A component;

[0104] (2) Preparation of component B: After mixing and dispersing the HDI curing agent and ether ester solvent evenly according to the ...

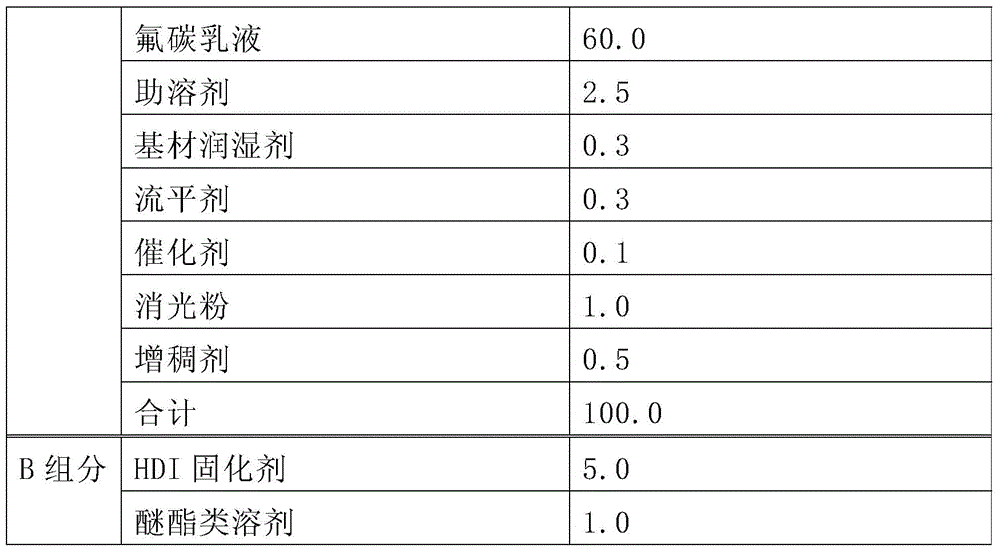

Embodiment 2

[0111]

[0112]

[0113] Described fluorocarbon emulsion is ETERFLON 4303 series products (made by Changxing Chemical Industry);

[0114] (1) Preparation of component A: first add deionized water according to the formula amount, slowly add anti-sedimentation agent under stirring, disperse until it becomes a uniform viscous slurry liquid, add wetting dispersant and defoamer and stir for 15 minutes , then add the pigment rutile titanium dioxide, disperse evenly, grind it with a grinder until the fineness is less than 10 μm, filter and remove the grinding medium, add fluorocarbon emulsion, co-solvent, substrate wetting agent, leveling agent, catalyst and matting powder, Disperse evenly and have a fineness of less than 30 μm. Finally, add a thickener, adjust the viscosity with deionized water, and filter and pack it to become A component;

[0115] (2) Preparation of component B: After mixing and dispersing HDI curing agent, IPDI curing agent and ether ester solvent evenly ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com