Method for producing 2,3-butanediol from recombinant Escherichia coli by the aid of glycerin

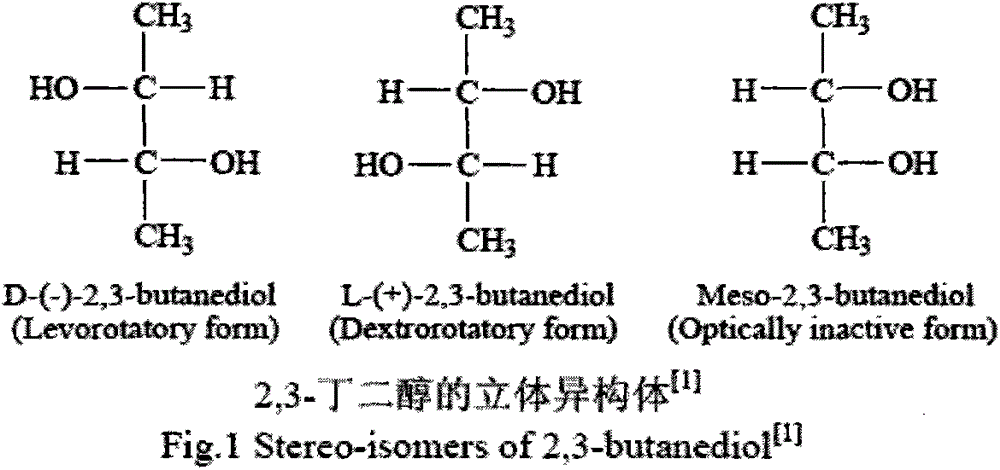

A technology of Escherichia coli and butanediol, which is applied in the field of recombinant Escherichia coli using glycerol to produce 2,3-butanediol, which can solve problems such as the worrying prospect of sugar as a substrate fermentation production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] 1) Cloning of gene fragments

[0112] Using primer sequence 1 and primer sequence 2, the gene fragment alsS was amplified. The PCR amplification conditions were: 95° C. for 30 S, 62° C. for 20 S, 72° C. for 90 S, 30 cycles, and 72° C. for 10 min. Using primer sequence 3 and primer sequence 4, the gene fragment alsD was amplified. The PCR amplification conditions were: 95° C. for 30 S, 62° C. for 20 S, 72° C. for 30 S, 30 cycles, and 72° C. for 10 min. Using primer sequence 5 and primer sequence 6, the gene fragment bdh was amplified, and the PCR amplification conditions were: 95° C. for 30 S, 62° C. for 20 S, 72° C. for 60 S, 30 cycles, and 72° C. for 10 min.

[0113] 2) Construction of plasmid

[0114] The amplified gene fragment alsS was digested with different restriction enzymes KpnI and SphI to obtain sticky ends, and the amplified gene fragment alsD was digested with different restriction enzymes SphI and SalI, To obtain sticky ends, the amplified gene fragment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com