Computer-controlled servo 3D bayonet tufted carpet machine

A tufted carpet and fully computerized technology, which is applied in the field of fully computerized servo 3D gun-barbed tufted carpet machine, can solve the problem that the carpet base fabric cannot be opened in a normal plane, the table-type tufting machine occupies a large area, and the secant mechanism cooperates consistently Poor performance and other problems, to achieve the effect of flexible layout, strong machine rigidity, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

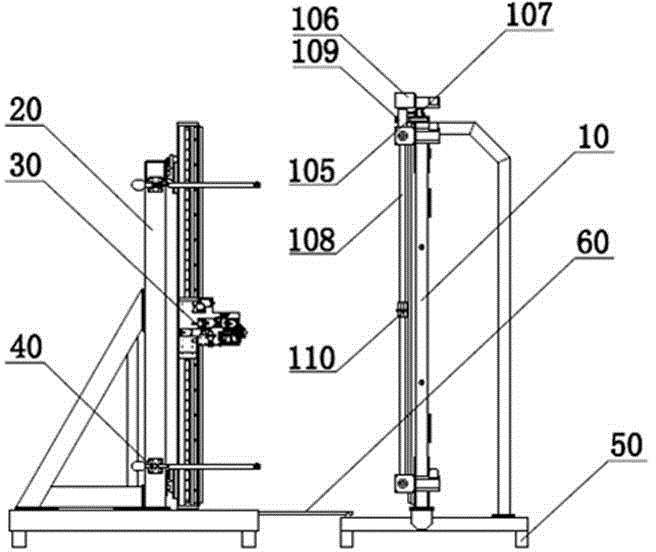

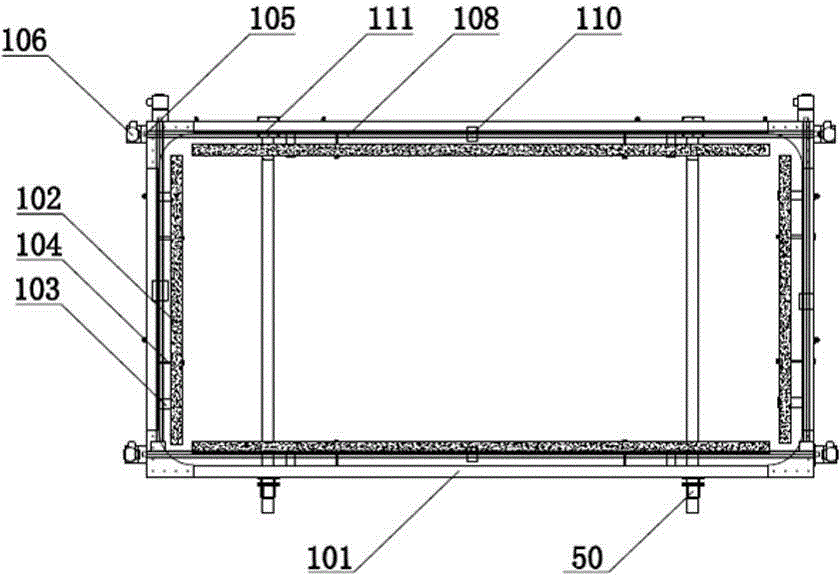

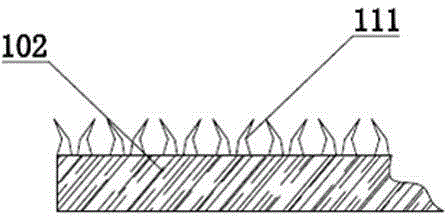

[0047] Example: such as figure 1 As shown, a full computer servo 3D gun-tufted carpet machine includes a group of front frames 10 and rear frames 20 facing each other, the front frame 10 includes a front frame 101 and a front support frame, and the rear frame 20 includes the rear The frame 112 and the rear support frame, the bottom of the front support frame and the rear support frame are all provided with castors 50, and the front frame 101 and the rear frame 112 are all rectangular and an elbow clamp 40 is arranged between them. A rear locking device is also provided between the front support frame and the rear support frame, and the locking device may be a positioning rod 60 . The front frame 101 is provided with a cloth locking mechanism that struts and binds the corners of the carpet base cloth, the rear frame 112 is provided with a displacement mechanism, the displacement mechanism is provided with a tuft head 30, and the tuft head 30 faces the front frame 101, and Driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com