Material passing device of cloths in dyeing machine

A material passing device, printing and dyeing machine technology, applied in the field of machinery, can solve the problems of unpublished cloth conveying technical scheme, unable to convey cloth, etc., and achieve high practical value and stable tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

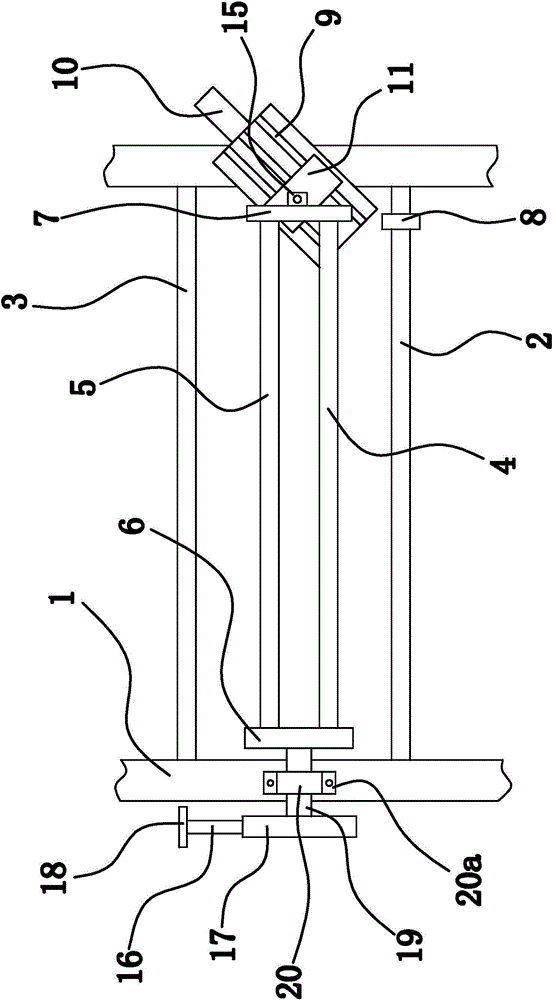

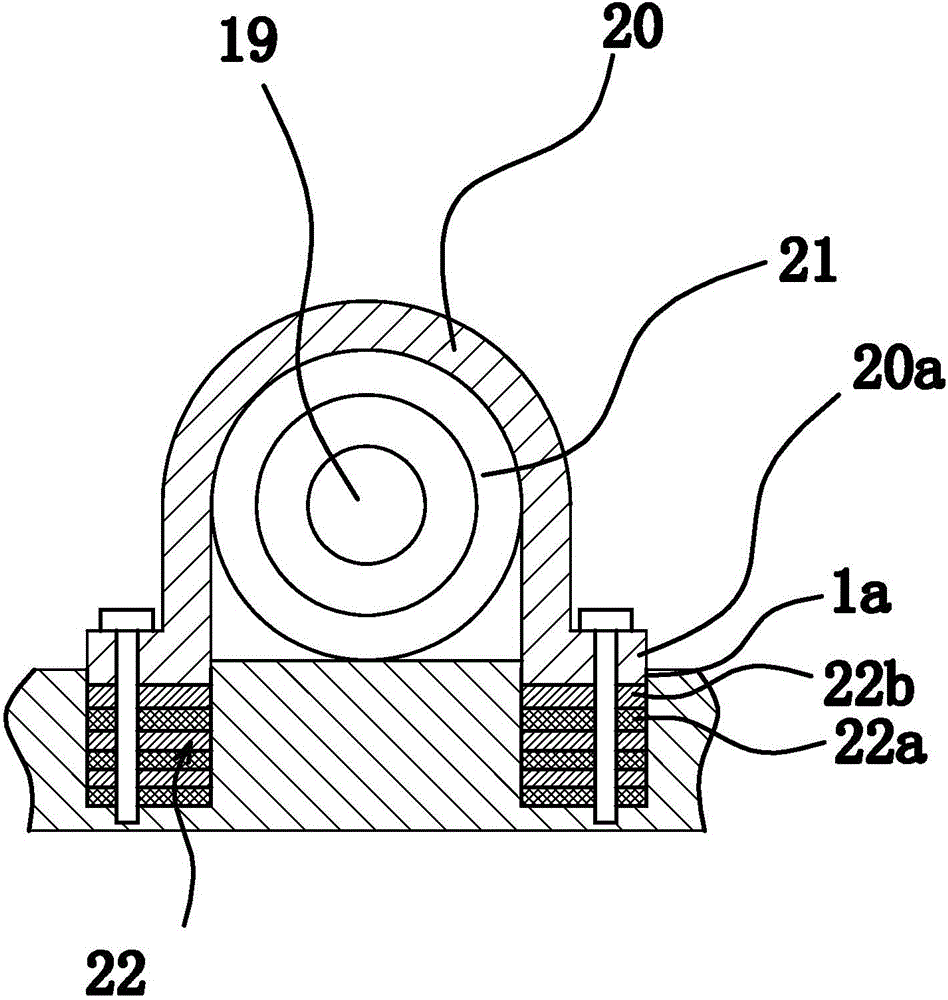

[0072] like figure 1 As shown, the printing and dyeing machine includes a frame 1 on which there is a printing and dyeing section for printing and dyeing. The material passing device of the cloth in this printing and dyeing machine is arranged on the frame 1 side of the printing and dyeing machine, and it includes a material passing roller 1 and a material passing roller 2 3 connected on the frame 1.

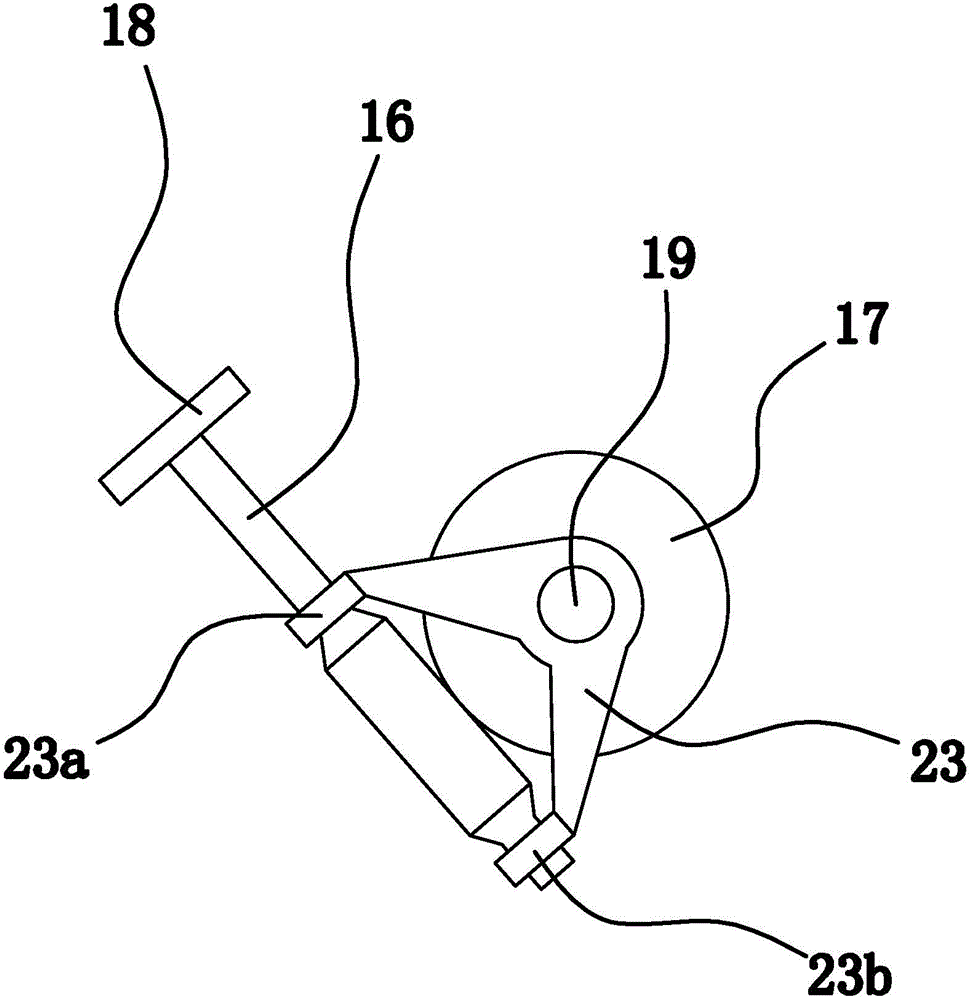

[0073] Material passing roller 1 2 and material passing roller 2 3 are arranged horizontally and parallel to each other. The material passing device also includes correction roller 1 4, correction roller 2 5, connection block 1 6, connection block 2 7 and sensor 8, correction roller 1 4 And the left end of correcting roller two 5 is all connected on the connecting block one 6, and the right end of correcting roller one 4 and correcting roller two 5 is all fixedly connected on the connecting block two 7.

[0074] The connecting block one 6 is hinged on the frame 1, and there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com