High-voltage line dual-T rod

A technology of high-voltage lines and lines, which is applied in the direction of towers, building types, buildings, etc., can solve the problems of many fault points, complex arrangement, high cost, etc., and achieve the effect of less land occupation, small size and less construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

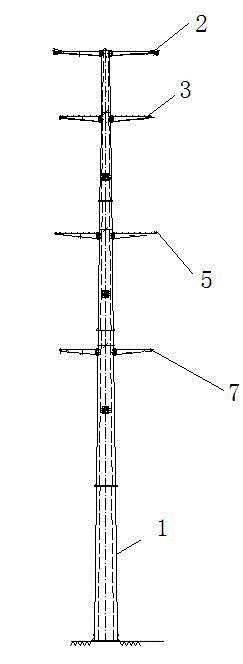

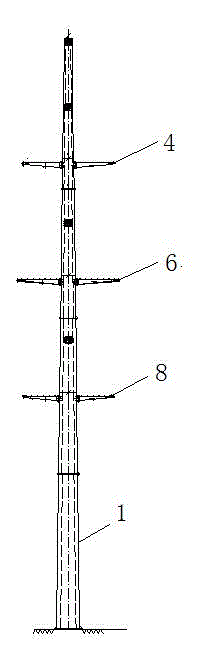

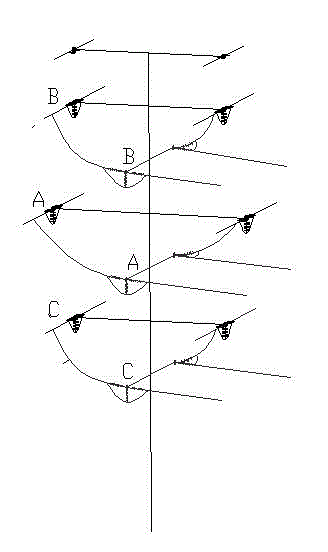

[0010] Such as Figure 1-3 As shown, the double T bar includes a vertical bar 1 and a lightning protection wire support 2, a conductor cross arm 3 on the original line, a conductor cross arm 4 on the double T line, a conductor cross arm 5 in the original line, and a conductor cross arm 6 in the double T line. 1. The lower conductor cross arm 7 of the original line and the lower conductor cross arm 8 of the double-T line are symmetrical from top to bottom on the vertical bar 1 and the lightning protection wire support 2 is installed at intervals. The original line upper conductor cross-arm 3 and the double-T line Conductor crossarm 4, conductor crossarm 5 in the original line, conductor crossarm 6 in the double T line, original line lower conductor crossarm 7 and double T line lower conductor crossarm 8, lightning protection wire support 2, original line upper conductor crossarm 3. The cross-arm 5 of the conductor in the original line, the cross-arm 7 of the lower conductor of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com