Oil mist separator

An oil mist separator and separation technology, applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., can solve the problem of limitation and achieve the effect of high flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

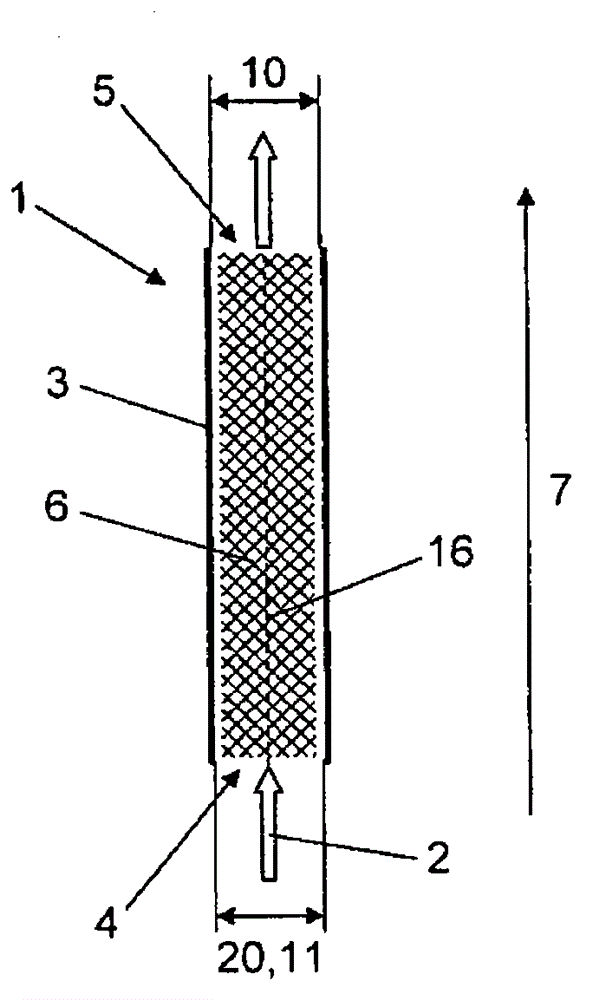

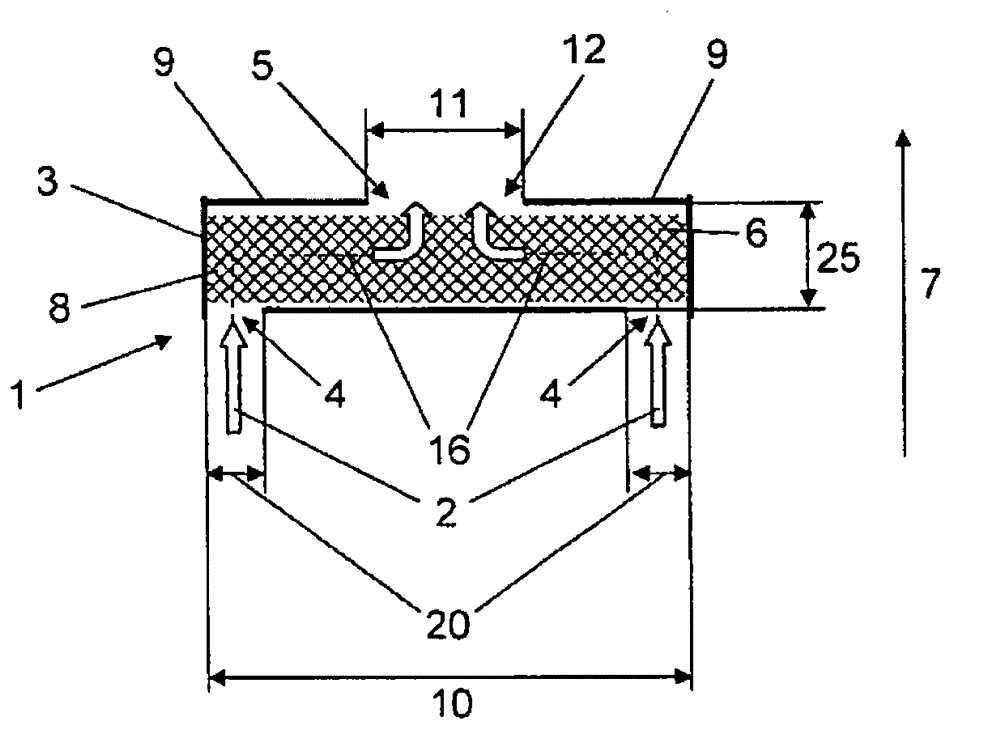

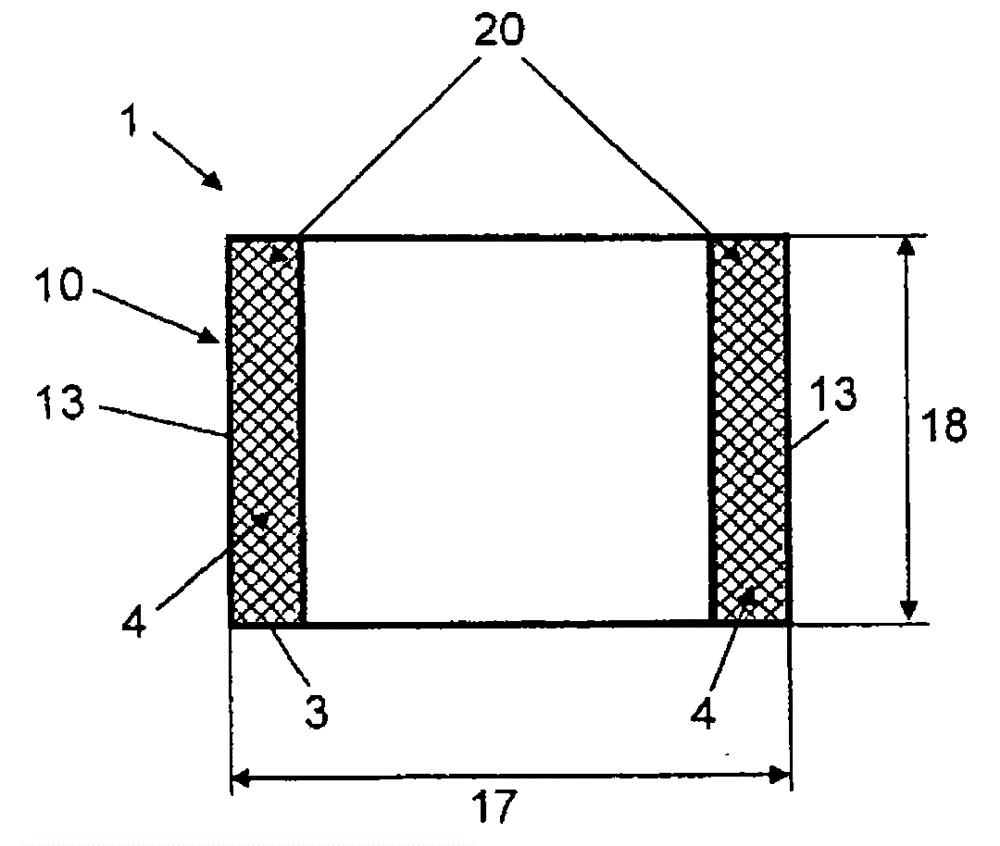

[0036] FIG. 1 shows a schematic sectional view of a filter device 1 according to the prior art, which comprises a housing 3 and a filter insert 6 arranged in the housing 3 . The housing 3 of the filter device 1 has an inlet 4 for introducing the carrier gas 2 into the filter device 1 and an outlet 5 for leading the carrier gas 2 filtered through the filter insert 6 out of the filter device 1 . The flow of the carrier gas 2 through the filter insert 6 along the flow path 16 (from which liquid suspended particles such as oil are to be separated) is indicated by the dashed line. The carrier gas 2 flows from the inlet 4 along the flow direction 7 through the filter device 1 to the outlet 5 . Transversely to flow direction 7 , in this exemplary embodiment housing 3 has a substantially rectangular cross section, so that transversely to flow direction 7 a rectangular housing cross-section 10 with clear inner width results. The inlet 4 of the housing 3 has a likewise rectangular inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com