Cabinet air conditioner

An air conditioner and cabinet type technology, applied in the field of cabinet type air conditioners, can solve the problems of low efficiency, high production cost, too many assembly screws, etc., and achieve the effects of preventing dust accumulation, improving assembly efficiency, and reducing assembly strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

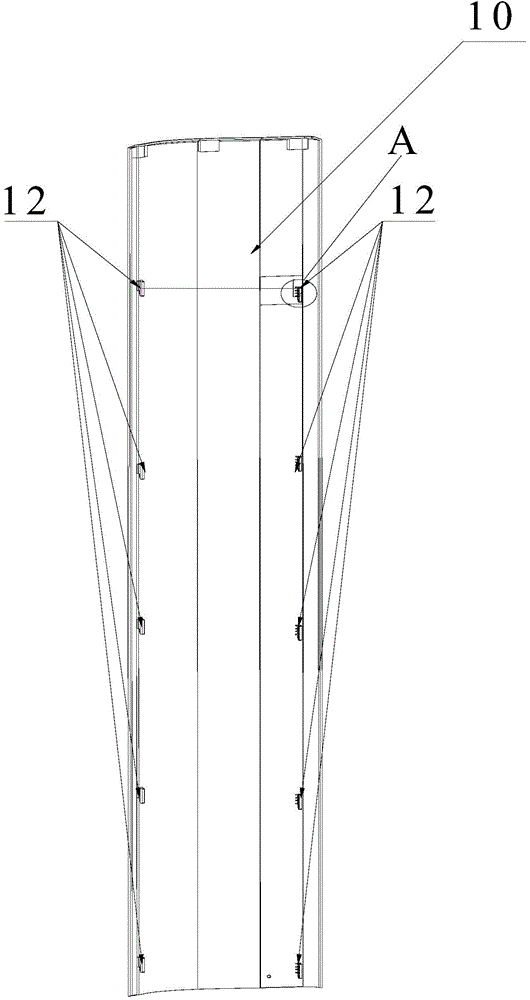

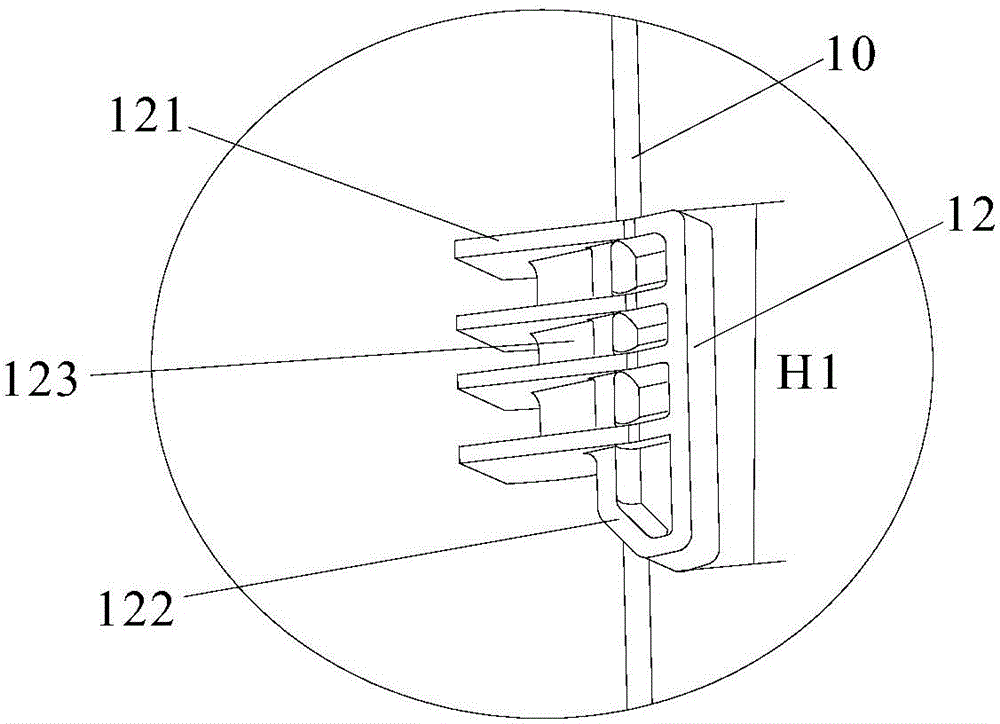

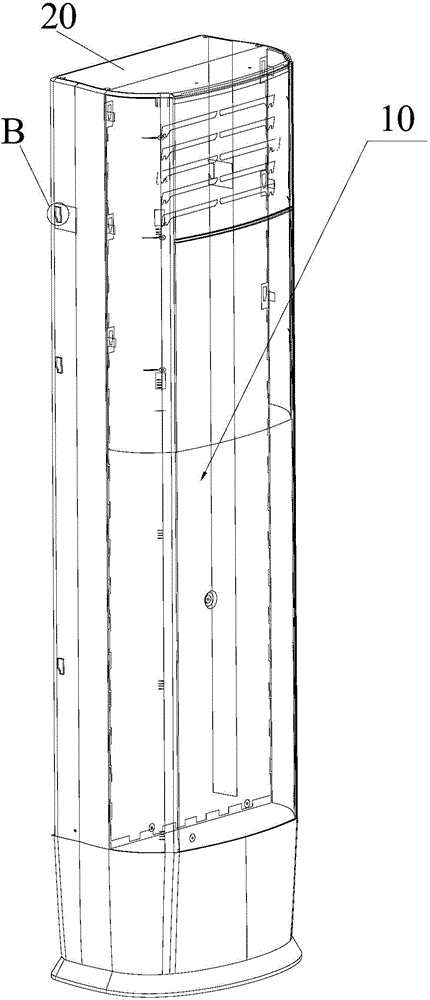

[0032] see Figure 1 to Figure 6 , according to the cabinet air conditioner of the present invention, comprising a housing 10 and a body 20, characterized in that the housing 10 is snap-fitted to the body 20, and the side wall of the housing 10 is provided with an inwardly inclined inner slope 11, The fuselage 20 is provided with an outwardly inclined outer slope 21 , and when the casing 10 and the fuselage 20 are snapped together, the inner slope 11 and the outer slope 21 are arranged in close contact. By setting the inclined surfaces that fit each other at the clamping joint of the shell and the fuselage, the screw connection is replaced by the clamping connection, which reduces the assembly strength and improves the assembly efficiency. Together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com