A plastic circular loom

A technology of circular looms and plastics, applied in circular looms, looms, textiles, etc., can solve problems such as easy accumulation of dust, influence on warp wire transportation and weaving quality, and unfavorable airflow, etc., to achieve large contact area and small quantity , to avoid the effect of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

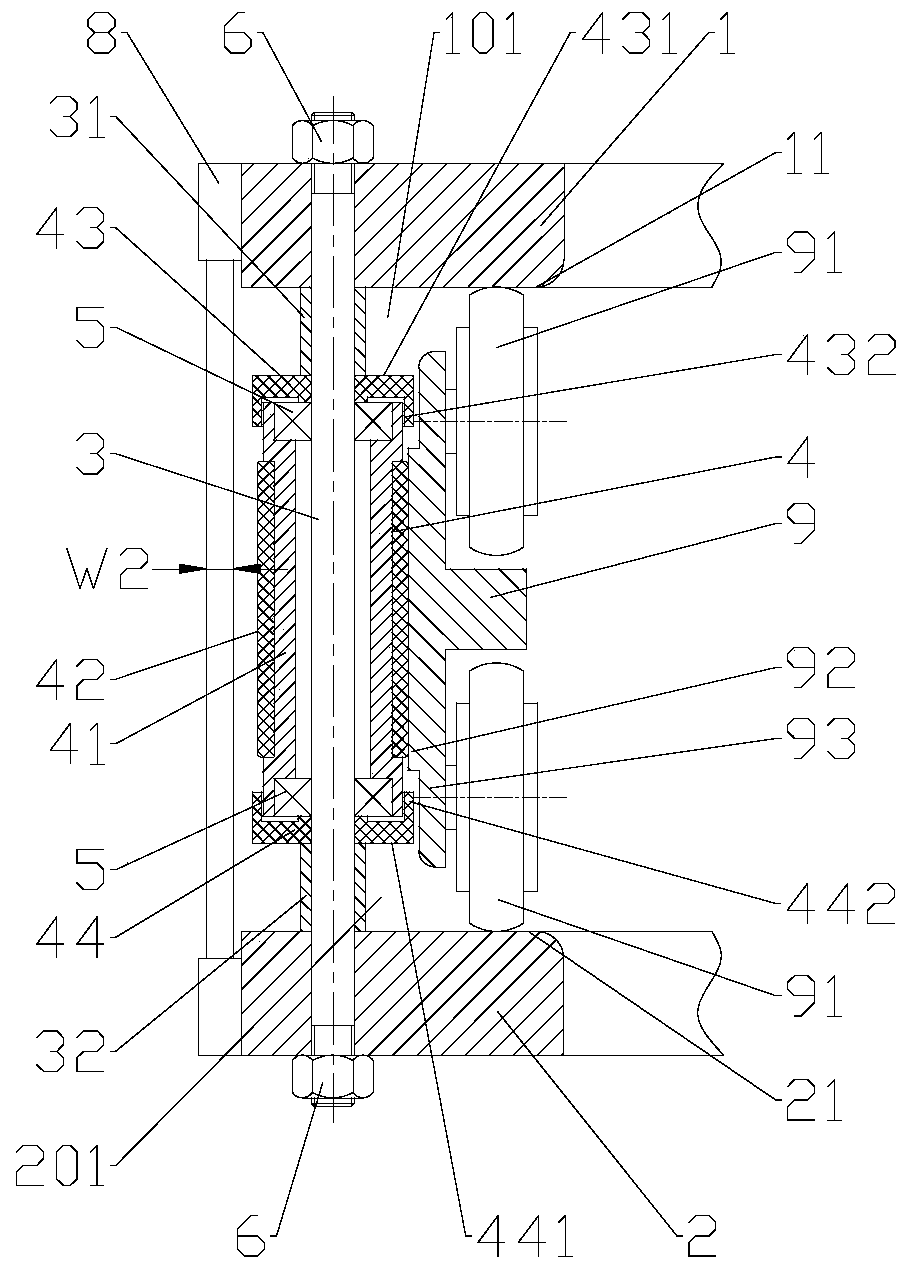

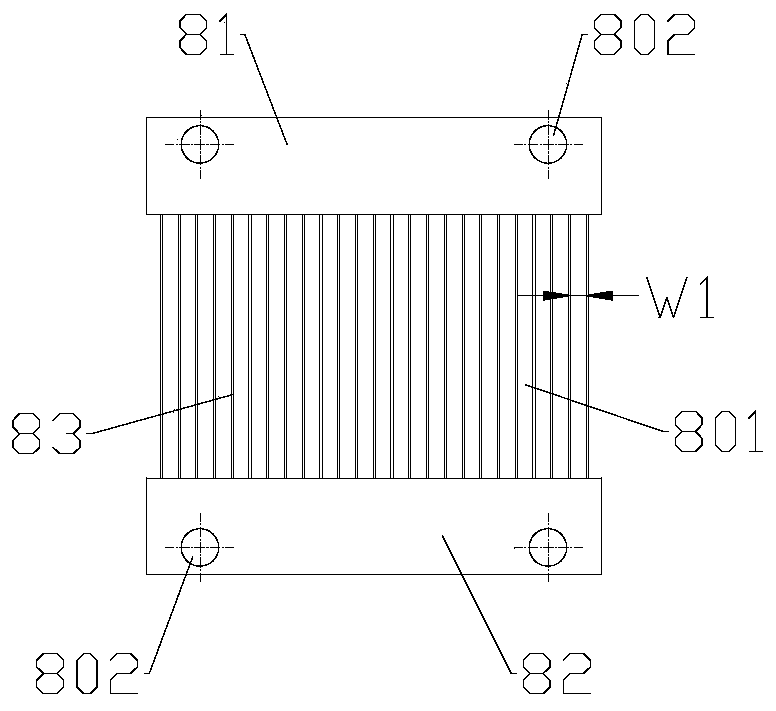

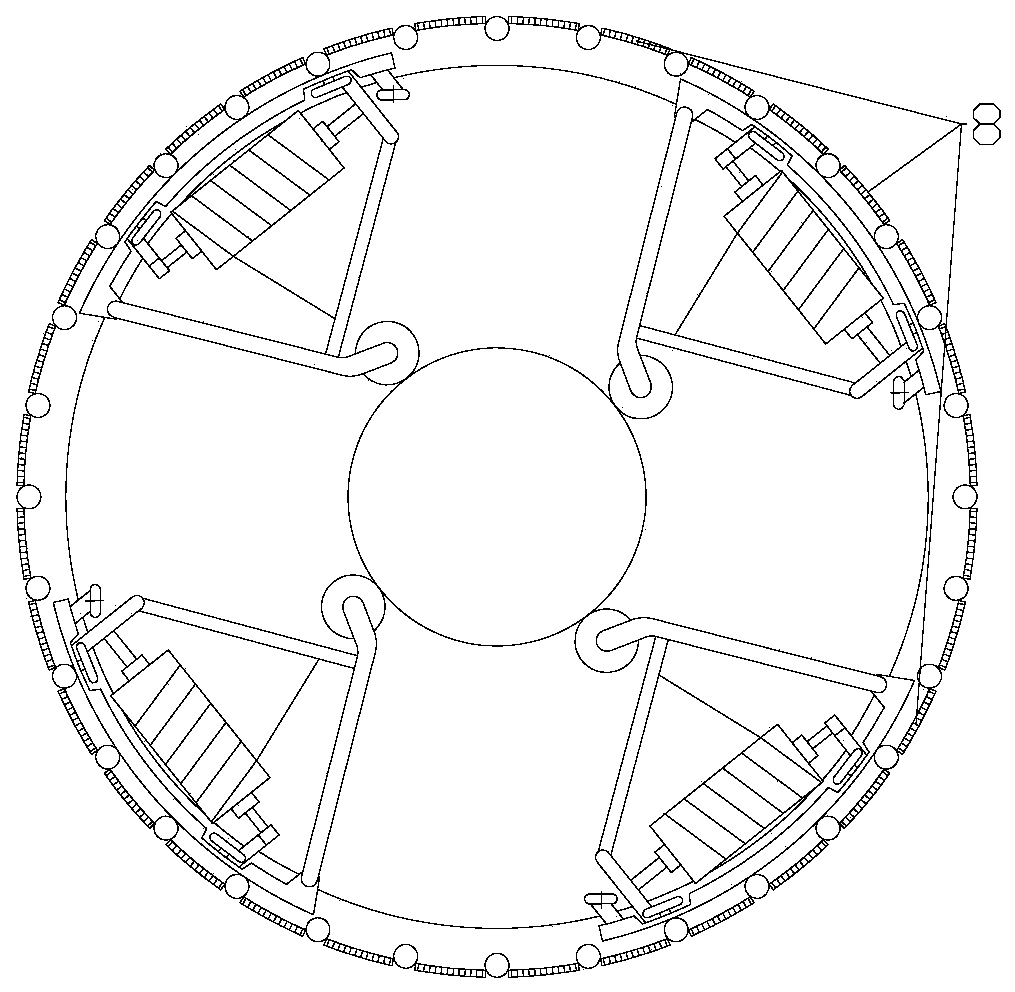

[0025] The invention provides a plastic circular loom, comprising a frame, a door ring assembly and a shuttle arranged on the frame. The door ring assembly includes an upper door ring 1 and a lower door ring 2, and a roller assembly is arranged between the upper door ring and the lower door ring , The roller assembly is arranged in multiple along the circumference of the door ring assembly, all the roller assemblies form a track for the shuttle 9 to run, such as figure 1 with figure 2 As shown, the roller assembly includes a mandrel 3 and a roller 4 sleeved on the mandrel 3. The lower surface 11 of the upper door ring 1, the upper surface 21 of the lower door ring 2, and two adjacent roller assemblies form a supply The thread passage through which the warp thread passes, the lower surface of the upper door ring and the upper surface of the lower door ring restrict the shuttle in the longitudinal direction. The outer circumference of the door ring assembly is provided with a warp...

Embodiment 2

[0038] reference figure 1 , In order to better guide the airflow to wash the lower surface of the upper door ring 1 and the upper surface of the lower door ring 2, the lower surface of the upper door ring and the upper surface of the lower door ring are both flat, the upper end of the drum 4 and the lower surface of the upper door ring An upper air outlet channel 101 is formed between the lower end of the drum 4 and the upper surface of the lower door ring 2. The shuttle runs at a high speed to squeeze the air flow outward and push the lower surface of the upper door ring and the upper surface of the lower door ring. The dust at the junction of the surface and the roller assembly is blown away. The lower surface of the upper door ring and the upper surface of the lower door ring are both flat, which can be understood as a plane parallel to the running plane of the shuttle 9. The planar structure is more conducive to the transport of warp yarns and reduces warp yarn wear. At the ...

Embodiment 3

[0045] Such as Figure 5 As shown, the cylinder 41 in this embodiment can be a simple hollow tube, and the bearing 5 is positioned by the retaining ring 45. The outer circumference of the cylinder 41 may not be provided with an annular groove, and the bottom surface of the shuttle 9 may not be provided with a boss. .

[0046] For other content not described in this embodiment, reference may be made to Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com