Spraying and cooling device for condenser of water chilling unit

A spray cooling and water chiller technology, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems affecting normal production, cooling pool overflow loss, and condensers unable to exchange heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

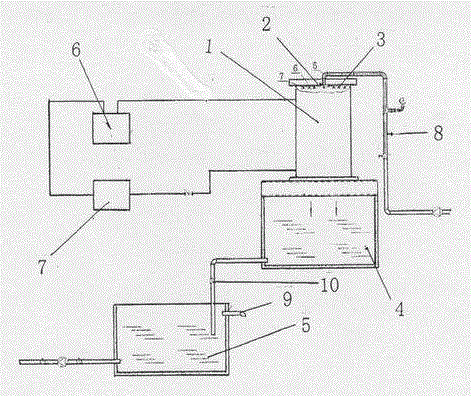

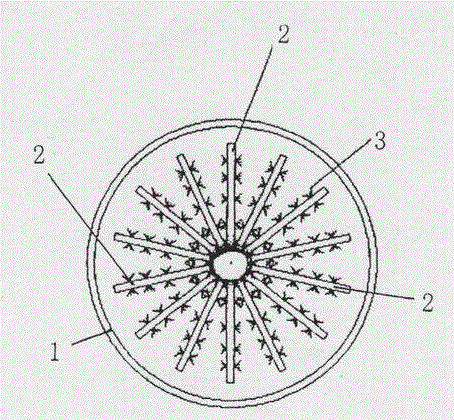

[0014] figure 1 , 2 As shown: the top of the condenser 1 connected with the compressor 6 and the evaporator 7 has a spray device composed of several spray pipes 2, the water pipe 8 is connected above the spray device, and the condenser 1 is sequentially provided with Cooling pond 4 and water storage pond 5. Several spray holes 3 that can spray evenly are distributed on several spray pipes 2 . Several spray pipes 2 are evenly combined into a whole in a fan-shaped structure, and the combined whole is consistent with the condenser. The upper end of water storage tank 5 is lower than the lower end of cooling tank 4, and the water pipe 8 that cooling tank 4 bottom communicates with storage tank 5 is equipped with stop valve 10. An overflow pipe 9 is arranged on the upper side of the water storage tank 5 .

[0015] When implementing the technical solution, the spray pipes 2 of the spraying device can be fan-shaped and distributed as 14, and its diameter can be made by welding 1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com