Aerial suspension airing device for materials

A technology of drying device and hanging device, which is applied in the direction of dryers for static materials, lighting and heating equipment, dryers, etc., which can solve the problems of seasonal influence, kelp body covered with sand, and low drying output, etc., to achieve The effect of reducing land pollution, saving labor costs, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

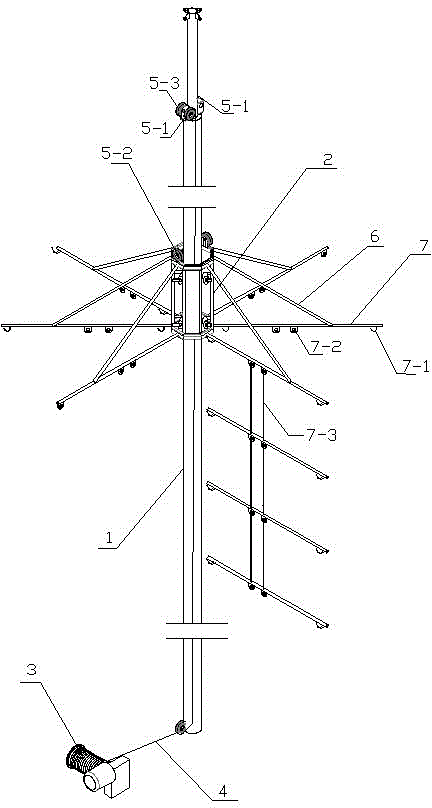

[0019] as attached figure 1 As shown, the high-altitude hanging drying device for materials includes a column 1 fixed on the ground. The column 1 is made of a hollow tube with a diameter of 30-60cm. The column 1 is provided with a lifting device that can move up and down. There is a material suspension device on the top.

[0020] In this embodiment, the lifting device is preferably configured as a lifting squirrel cage 2, a winch 3 and a pull rope 4, as attached figure 1 As shown, the column 1 is located inside the lifting squirrel cage 2, and the winch 3 is located at the bottom of the column.

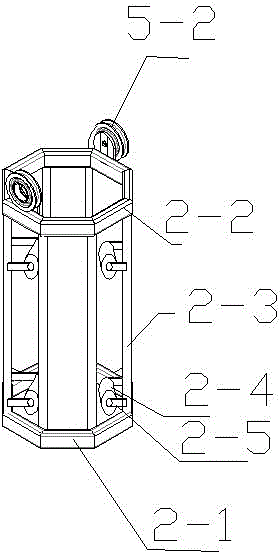

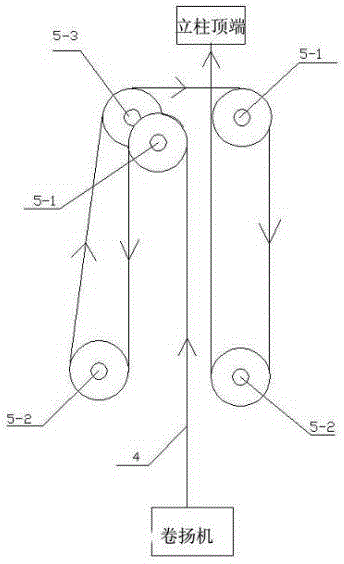

[0021] as attached figure 1 As shown, the top of the column 1 is provided with a first direction-changing pulley 5-1, and the top of the elevating squirrel cage 2 is provided with a second direction-changing pulley 5-2. figure 2 As shown, in order to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com