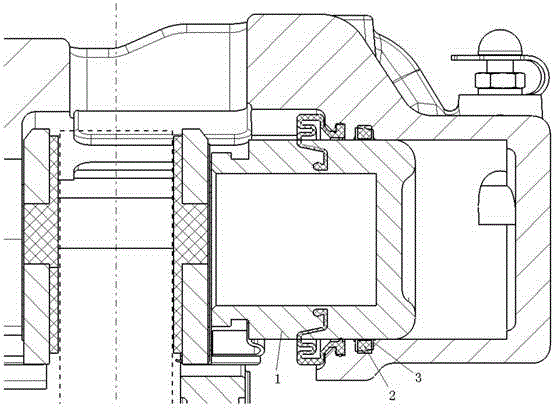

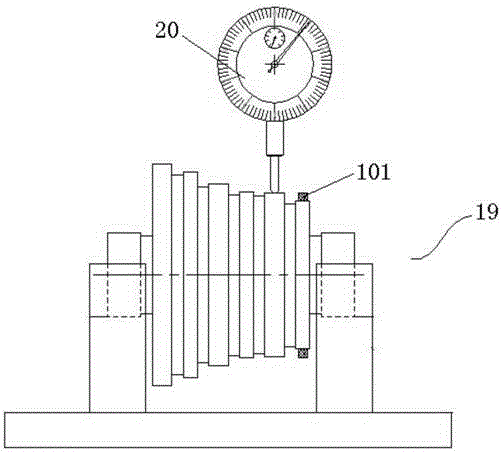

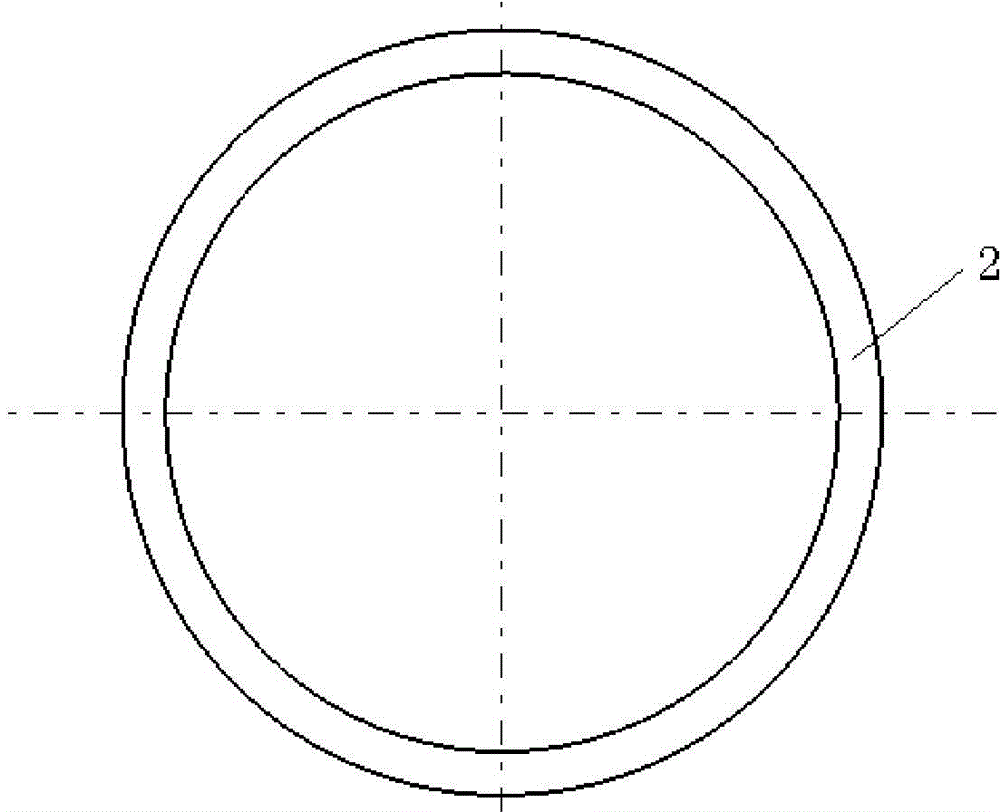

Rubber sealing ring measuring tool and rubber sealing ring measuring method

A technology of rubber sealing ring and measuring tool, which is applied in the direction of mechanical diameter measurement, angle/taper measurement, etc. It can solve the problems of small size of rubber sealing ring, large numerical deviation, inability to guarantee roundness, etc., to ensure quality and optimize measurement method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0035] What is explained here is that the present invention is only applicable to the measurement of rubber sealing rings, and is not suitable for the measurement of sealing rings made of other materials, such as graphite sealing rings or polymer plastic sealing rings. This is mainly to measure the outer diameter of the sealing ring When measuring, the elastic coefficient of graphite or polymer plastic is low, and its deformation can sometimes be ignored, so its measurement structure is not accurate. On the other hand, other sealing rings have a low degree of deformation, therefore, it is not necessary to use the technical solution of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com