A dynamic loading device for driving components of a railway locomotive

A driving component and dynamic loading technology, which is applied in the testing of machine/structural components, measuring devices, railway vehicle testing, etc., to achieve the effects of increasing safety and stability, expanding the scope of application, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

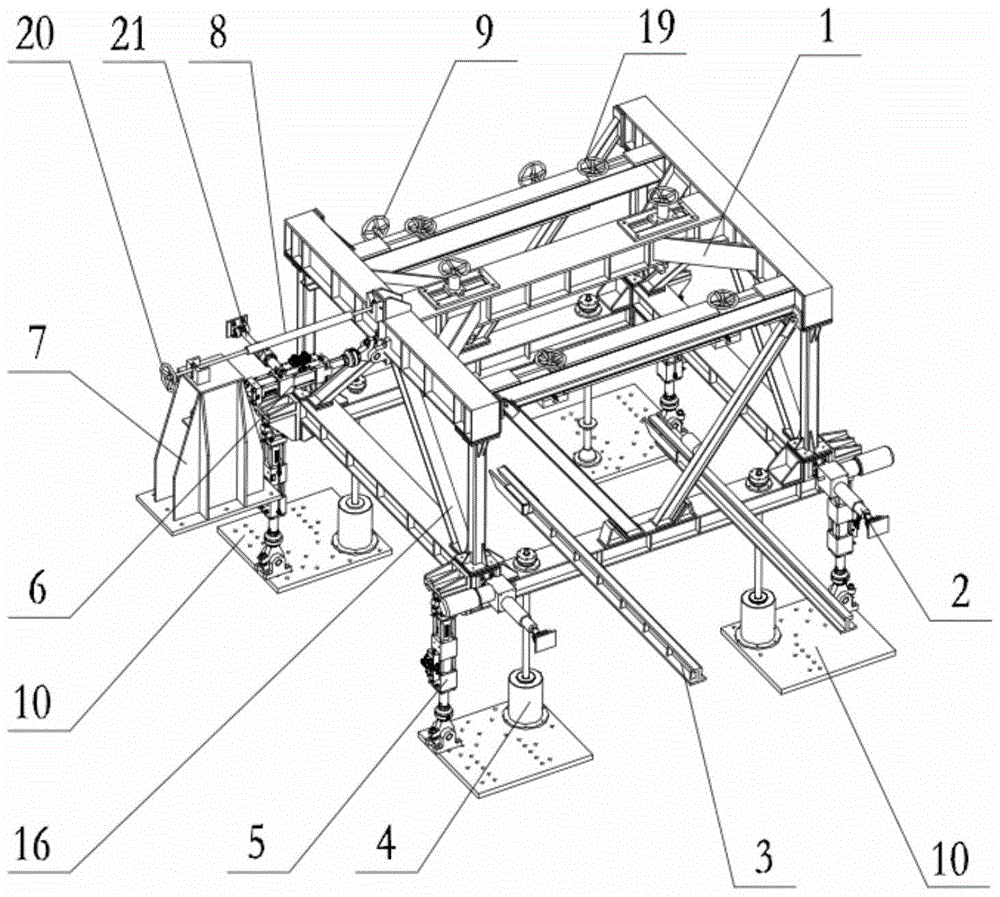

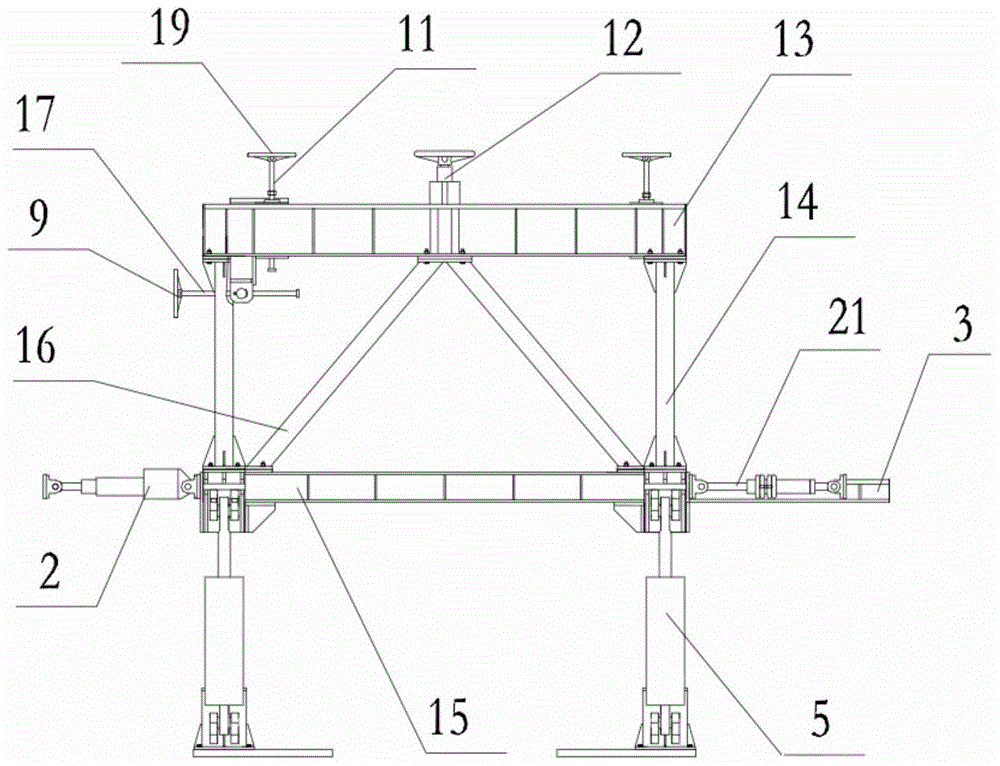

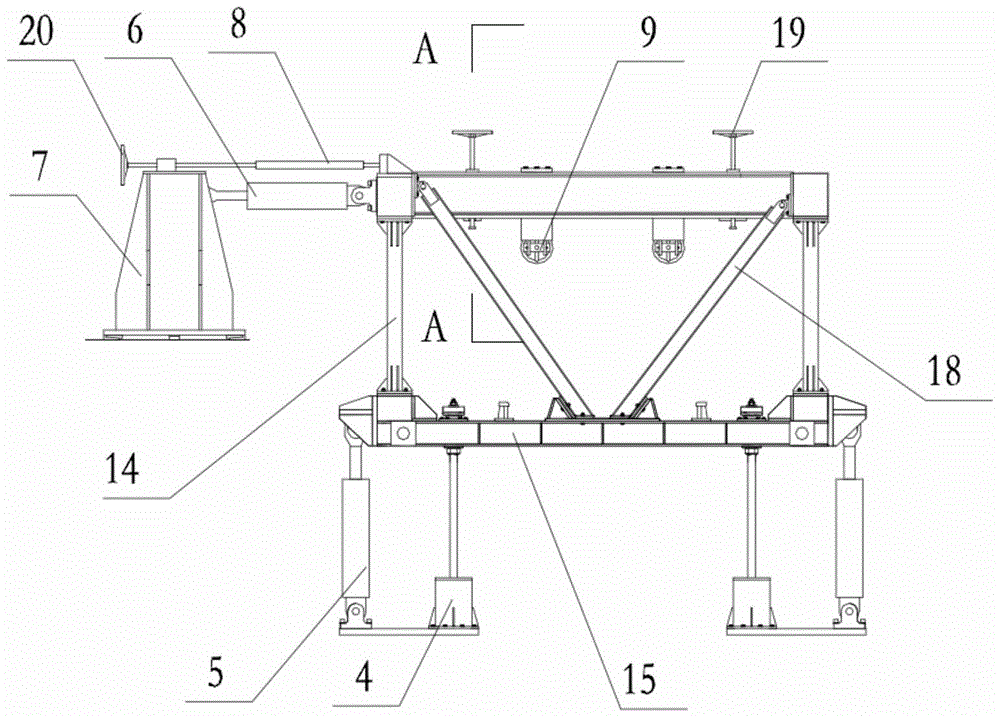

[0063] The present invention will be further described below by accompanying drawing:

[0064] A dynamic loading device for a driving part of a railway locomotive, comprising a vertical oil cylinder 5 and a transverse oil cylinder 6 arranged on a mounting plate 10 and connected to a loading frame 1 . Both ends of the vertical oil cylinder 5, the horizontal oil cylinder 6 and the longitudinal electric push-pull rod 2 are provided with ball hinges, one end of the vertical oil cylinder 5 is fixed to the mounting plate 10, and the other end of the ball hinge seat is connected to the lower frame 15, One end of the horizontal oil cylinder 6 is connected to the horizontal reaction force frame 7, and the other end is connected to the left side beam 23 of the upper frame 13; The two ends of the side beams are connected, and the ball hinge seats at one end of the two limit push-pull rods 21 are respectively connected with the two ends of the rear side beam of the lower frame 15; the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com