Coal rock mechanical parameter detector and method for measuring mechanical parameters of coal rock

A technology of mechanical parameters and detectors, applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problem of inability to accurately reflect the mechanical properties of dynamic changing conditions of coal and rock, difficulty in showing the complexity of crack changes in coal and rock specimens, and inability to Accurately reflect the dynamic changes of cracks in coal and rock specimens, and achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

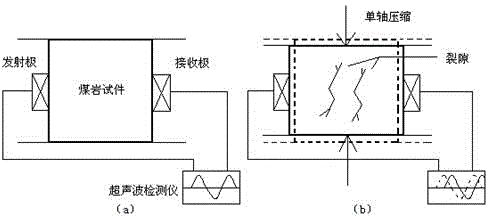

[0014] Coal rock mechanical parameter detector of the present invention, its specific implementation mode is as follows figure 1 As shown, it includes a uniaxial press and an ultrasonic detector, the uniaxial press includes a jack with a pressure reading gauge, an upper working platform, a lower working platform, a movable platform and a fixed screw, and the ultrasonic detector includes an emitter , receiving pole and signal processing unit.

[0015] The above-mentioned coal-rock mechanical parameter detector of the present invention measures the method for coal-rock mechanical parameter, and its specific embodiment is:

[0016] Firstly, the coal rock test piece is placed on the movable platform of the uniaxial press, and the emitter and receiver electrodes of the ultrasonic detector are fixed on both sides of the coal rock test piece. The emitter of the ultrasonic detector emits ultrasonic signals through the coal rock test The receiving pole of the ultrasonic detector recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com