Acquisition and dumping method and system thereof for machining process data of numerical control system

A technology of numerical control system and processing process, which is applied in the field of numerical control system and machine tools, can solve the problems of unable to collect and record internal instruction data, etc., and achieve the effect of long-term uninterrupted and comprehensive data types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

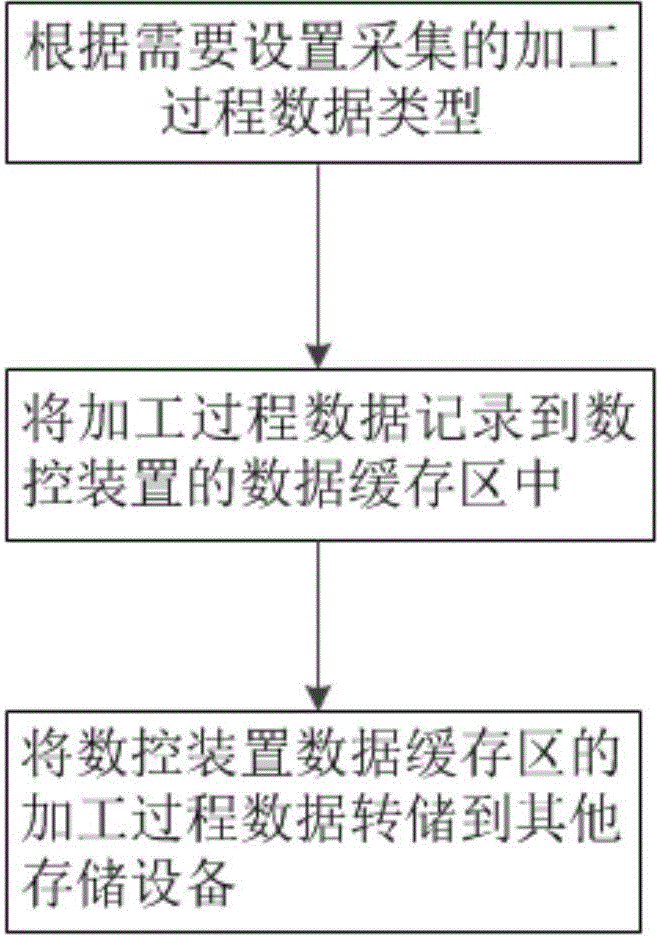

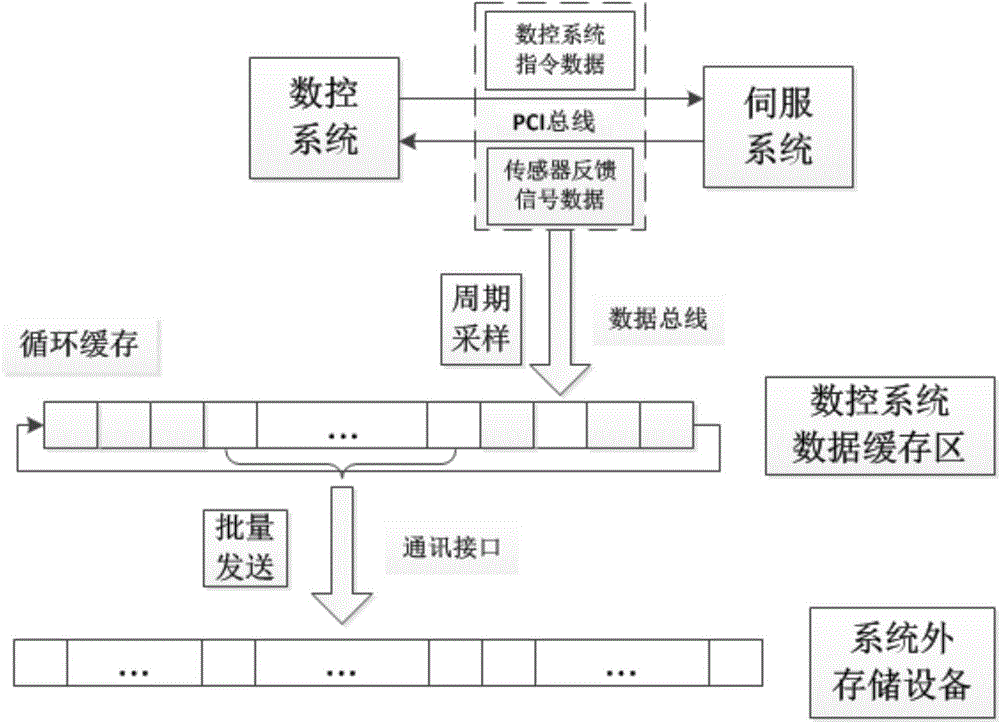

[0028] Refer to attached figure 1 , the processing process data acquisition and dump flow chart that the present invention proposes, mainly has three steps, and step one is to set the processing process data type of collection in the data acquisition interface, and step two is to record the processing process data to the numerical control during the processing process. In the data buffer area of the device, the third step is to dump the processing data in the data buffer area of the numerical control device to other large-capacity storage devices.

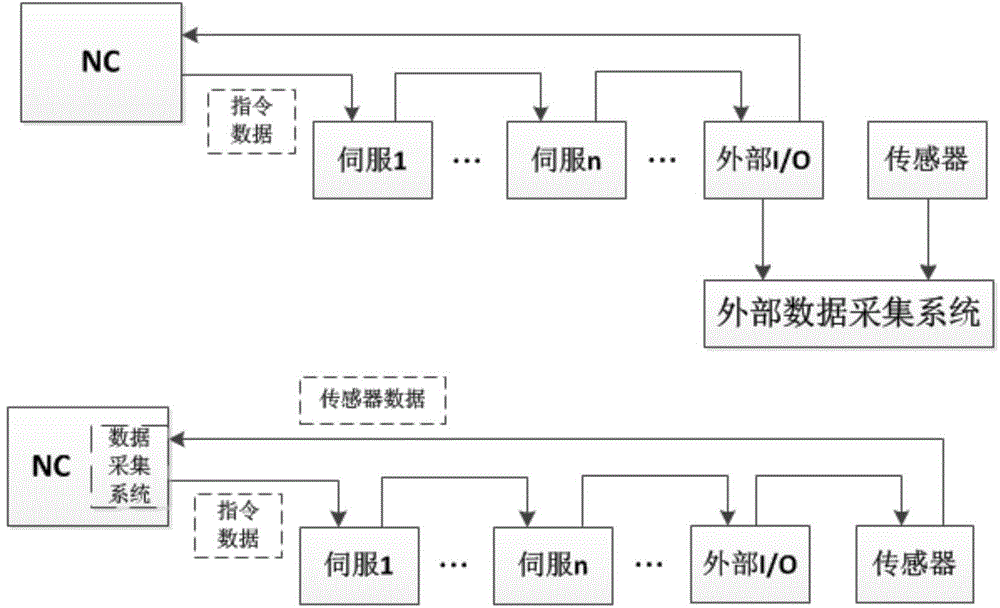

[0029] attached figure 2 Shown is a comparative schematic diagram of the common external data collection method and the data collection method of the present invention, wherein the upper figure corresponds to the common external data collection method, and the lower figure corresponds to the data collection method of the present invention. The CNC system controls the servo system with instruction data, which are transmitted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com