Control level management method for ultra-large ship power station

A management method and power station technology, applied in the direction of electrical program control, general control system, program control, etc., can solve the problems of power supply area management exceeding, traditional design methods cannot be effectively applied, and cross-power station control management cannot be realized, so as to achieve high reliability Sexual indicators, the effect of flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the following embodiments, unless otherwise specified, all the components mentioned are conventional equipment.

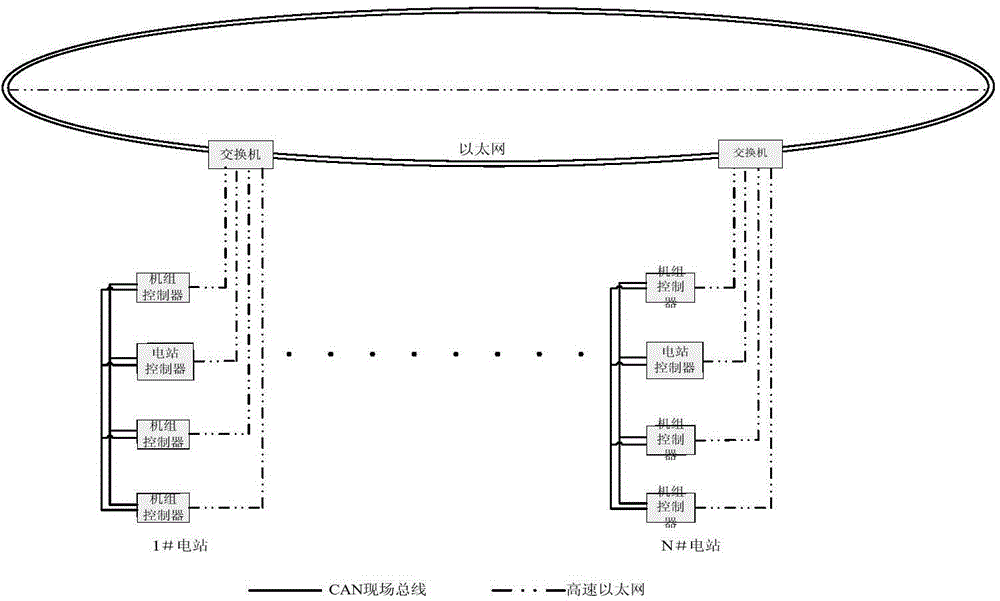

[0052] like figure 1 As shown, in one implementation, the management method of the present invention is used in a power supply monitoring system of a large ship, and the composition of the power supply monitoring system of the large ship is as follows:

[0053] overall composition

[0054]

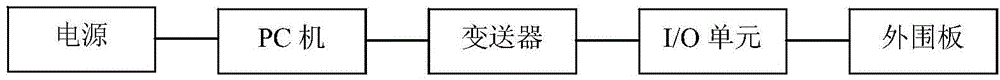

[0055] Structure and interface

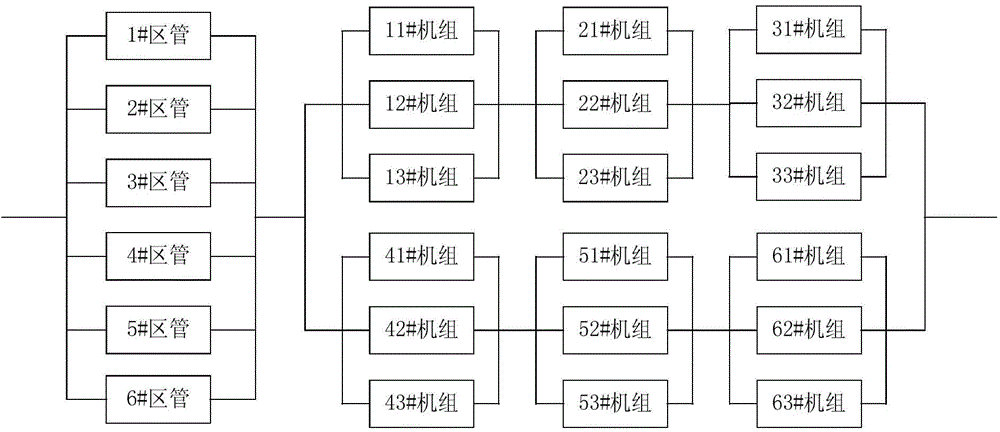

[0056] For the upper console, the power station control device monitoring component (area manager) and the terminal equipment of the power station monitoring console, power centralized control console, and power backup centralized console exchange information and instructions through the CAN bus network communication protocol. In consideration of reliability and modular design, the CAN bus communication network is divided into 6 subnets.

[0057] For the machine-side monitoring box, the unit controller of the power station contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com