Intelligent proportioning method and system based on RFID (radio frequency identification) and data mining

A technology of intelligent batching and data mining, applied in data processing applications, instruments, sensing record carriers, etc., can solve problems such as difficulty in reaching, low efficiency, etc., and achieve a high degree of intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

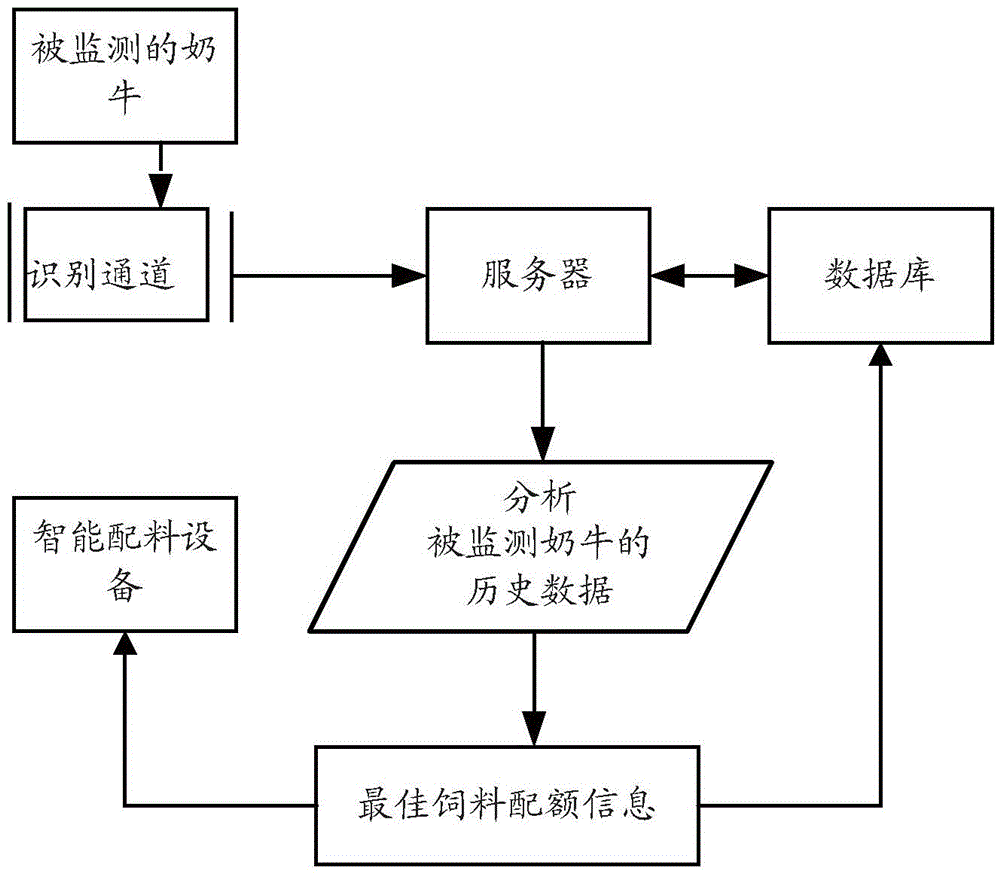

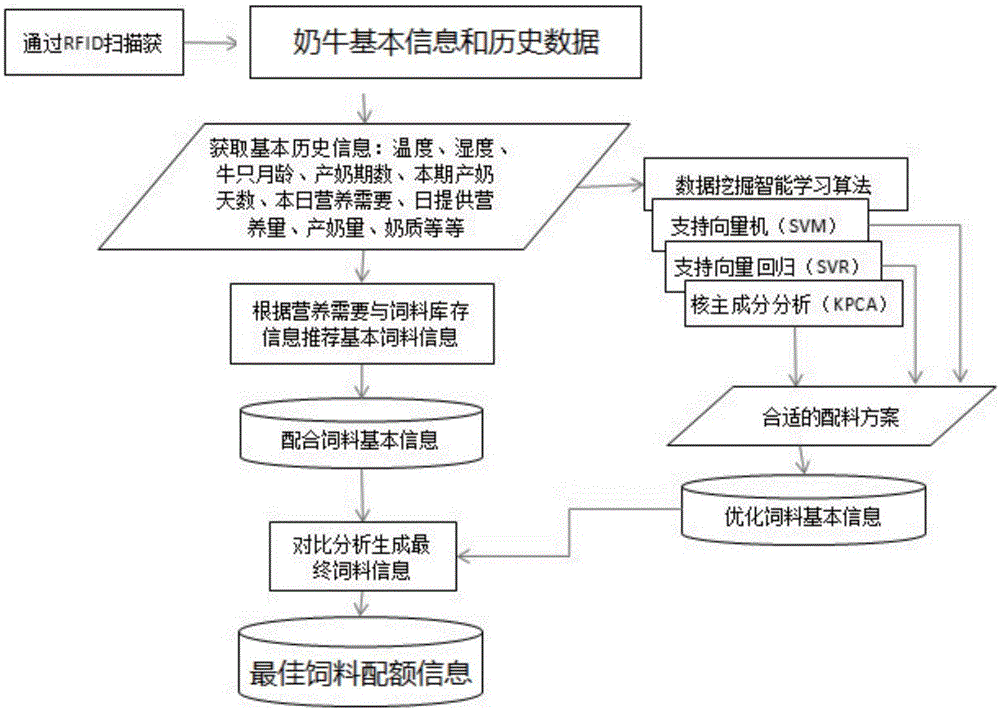

[0027] Such as figure 1 As shown, the present invention provides a kind of intelligent batching method based on RFID and data mining, comprises the following steps:

[0028] S1, fixing an RFID tag on the body of each monitored cow, the RFID tag has a unique number for identifying the monitored cow, and at the same time, storing the basic information of the cow in the RFID tag;

[0029] S2, making the monitored cows pass through the identification channel equipped with a card reader, the card reader reads the basic information of the cows stored in the RFID tag, and transmits the read basic information of the cows to the server through the network ;

[0030] S3, the server receives the basic information of the dairy cow, and reads the database to obtain the historical data of the monitored dairy cow; through analysis and calculation of the basic information and historical dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com