Board for stringed instrument, method of manufacturing board for stringed instrument, and stringed instrument

一种弦乐器、板材的技术,应用在弦乐器、乐器、仪器等方向,能够解决需要时间、物料收率低、不能获得外观等问题,达到抑制变形、密度差异小、声学特性优越的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

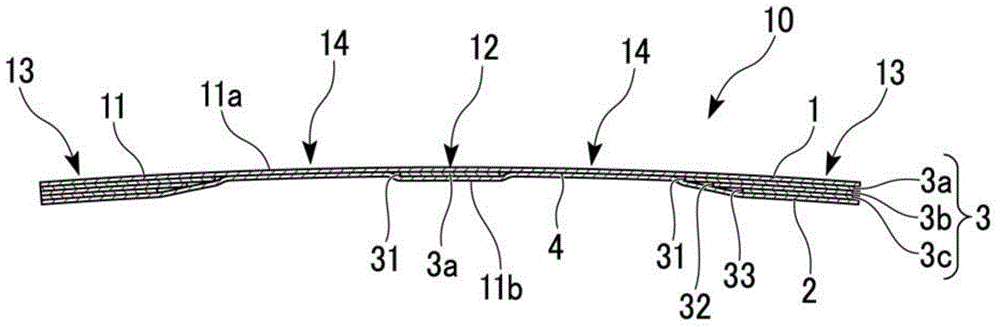

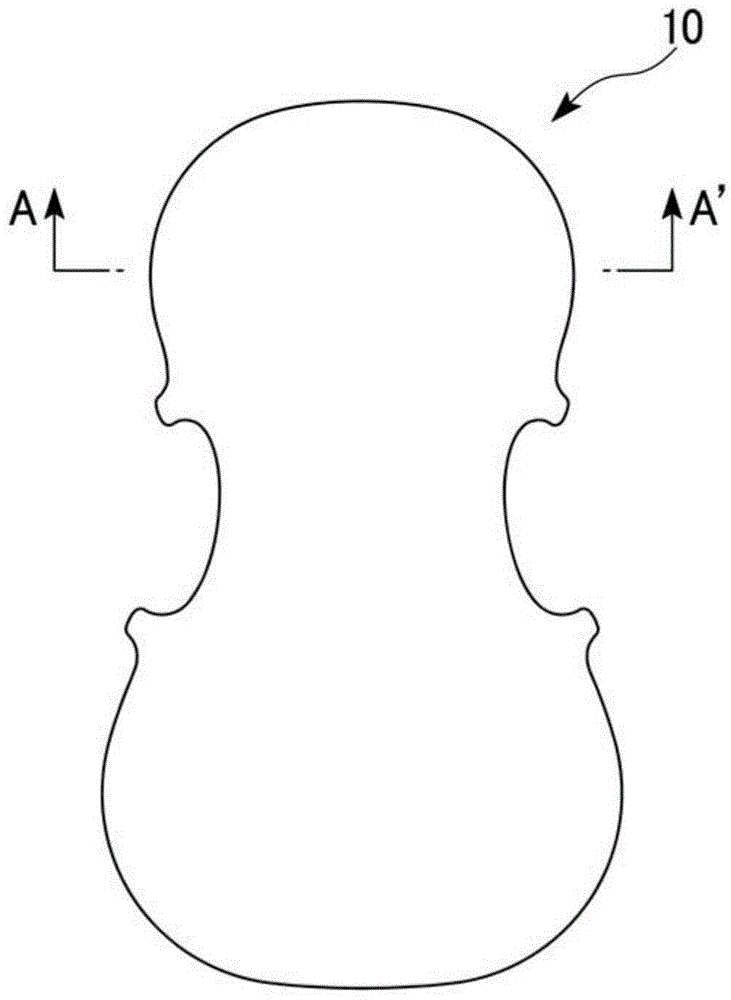

[0029] In this embodiment, a front plate of a violin is described as an example of a plate for a stringed instrument according to the present invention. Figure 1A is a sectional view along the width direction of the panel of the violin according to the first embodiment of the present invention. Figure 1B is showing Figure 1A Floor plan of panel shown. Figure 1A is along Figure 1B A cross-sectional view taken along the line A-A'.

[0030] like Figure 1A As shown, the panel 10 of the violin includes a laminated board 11 having an arcuate shape, and the laminated board 11 is bent to face the front surface 11a ( Figure 1A top surface) is curved on one side.

[0031] The thickness of the laminated board 11 is partially different, such as Figure 1A shown. Regarding the thickness of the laminated board 11 , the thickness of the peripheral edge 13 is the thickest, the thickness of the central portion 12 is the second thickest, and the thin portion 14 is formed between the cen...

no. 2 example

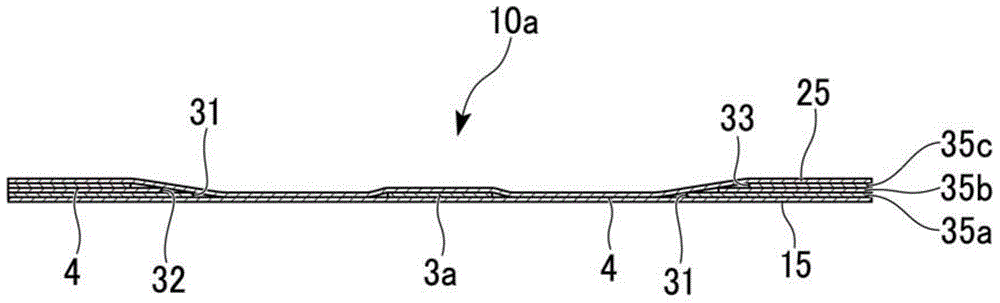

[0070] In this embodiment, a back plate of a violin will be described as an example of a plate material for a stringed instrument according to the present invention.

[0071] According to the backboard of the violin of this embodiment and according to Figure 1A The panel 10 of the first embodiment shown is different in that: taking into account the function of the back panel, the plane shape of the veneer forming the core panel is determined according to the thickness distribution; and preferably, used as a front surface panel, a rear surface panel And the material of the core board is maple.

[0072] In the back panel according to this embodiment, it is more preferable that the front surface panel, the rear surface panel and the core panel are all made of maple wood. By allowing all the veneers to be made of maple, a better function as a backboard can be obtained and the sound quality of a violin using this backboard can be further improved. Furthermore, in the back panel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com