Apparatus and method for manufacturing electronic component

A technology for electronic components and manufacturing equipment, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of electronic components 29 falling, unoptimized, static electricity, etc., to reduce the installation area, improve the operation rate, and improve the The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

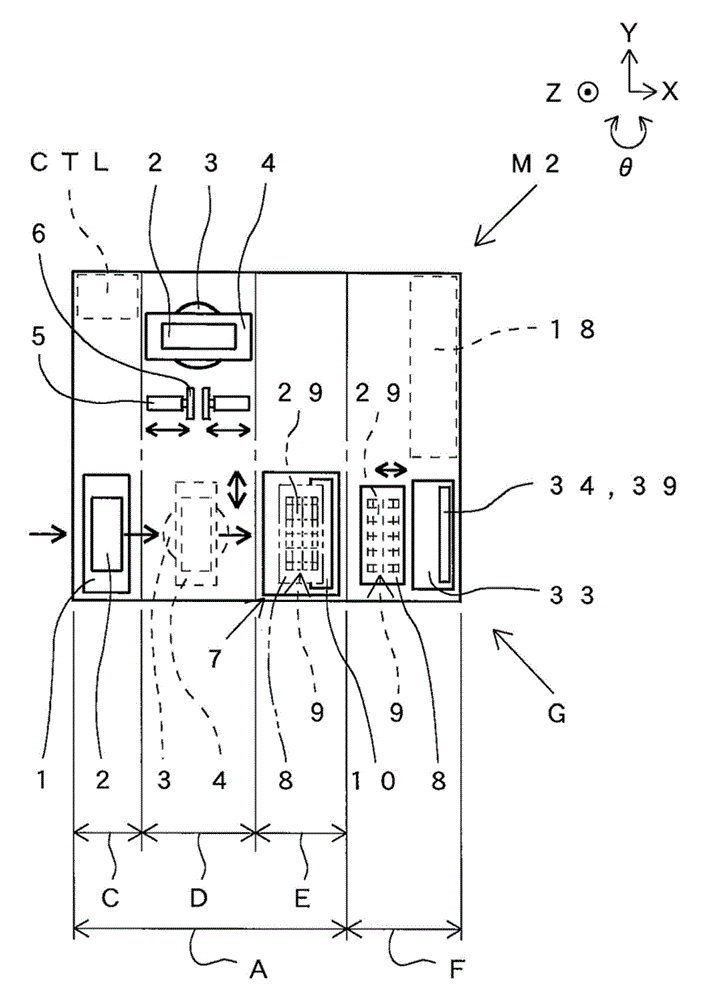

[0119] refer to image 3 with Figure 5 , Example 1 of the manufacturing apparatus M2 and the manufacturing method of the electronic component 29 using the manufacturing apparatus M2 will be described. Such as Figure 5 As shown, the scraping member 39 used in this embodiment is composed of a rigid member. More specifically, the scraping member 39 has a plurality of rod-shaped members 40 having rigidity. The rod member 40 has a cylindrical shape. The intervals between the plurality of bar-shaped members 40 are preferably smaller than the minimum size of the electronic component 29 (generally, the dimension in the thickness direction (Z direction in the figure)). In addition, regarding this case, that is, when it is preferable that the interval between a plurality of components (in this embodiment, a plurality of rod-shaped components 40 ) is smaller than the minimum value of the size of the electronic component 29, in other implementations described later, The same applie...

Embodiment 2

[0127] refer to image 3 and Figure 6 , Example 2 of the manufacturing apparatus M2 and the electronic component 29 using the manufacturing apparatus M2 will be described. Such as Figure 6 As shown, the scraping member 39 used in this embodiment has a single plate-shaped member 41 composed of a rigid member.

[0128] The single plate member 41 included in the scraping member 39 scrapes off the plurality of electronic components 29 from the first conveying mechanism 8 by the movement of the first conveying mechanism 8 . The scraped-off electronic components 29 are housed in the storage box 29 .

[0129] According to this embodiment, the same effect as that of the embodiment described above can be obtained. In particular, since the scraping member 39 having the single plate-like member 41 is used, the phenomenon that the electronic part 29 is caught in the scraping member 39 never occurs. Therefore, since the electronic component 29 is reliably accommodated in the storage...

Embodiment 3

[0131] refer to image 3 and Figure 7 , Example 3 of the manufacturing apparatus M2 and the electronic component 29 using the manufacturing apparatus M2 will be described. Such as Figure 7 As shown, in this embodiment, a switching valve 42 is provided on the suction pipe 36 connected to the suction pump 18 . The switching valve 42 and the suction pump 18 are connected through the suction pipe 36 . The switching valve 42 and a high-pressure gas source (not shown) are connected through a pipe 43 for injection. In the present embodiment, the suction duct 36 between the switching valve 42 and the first transport mechanism 8 also functions as an injection duct. As the high-pressure gas source, a high-pressure air source that is utility equipment (Utilities) in an electronic component manufacturing plant can be used.

[0132] Next, the operation of the manufacturing apparatus of this embodiment will be described. First, the suction pump 18 and the suction pipe 36 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com