Method for using polyurethane adhesive to encapsulate electrical connector product

An electrical connector and polyurethane adhesive technology, which is applied in the field of potting reliability of electrical connector products, can solve the problems of sealing failure and overflow of potting products, so as to improve the airtight pass rate, increase the curing temperature, and improve the bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

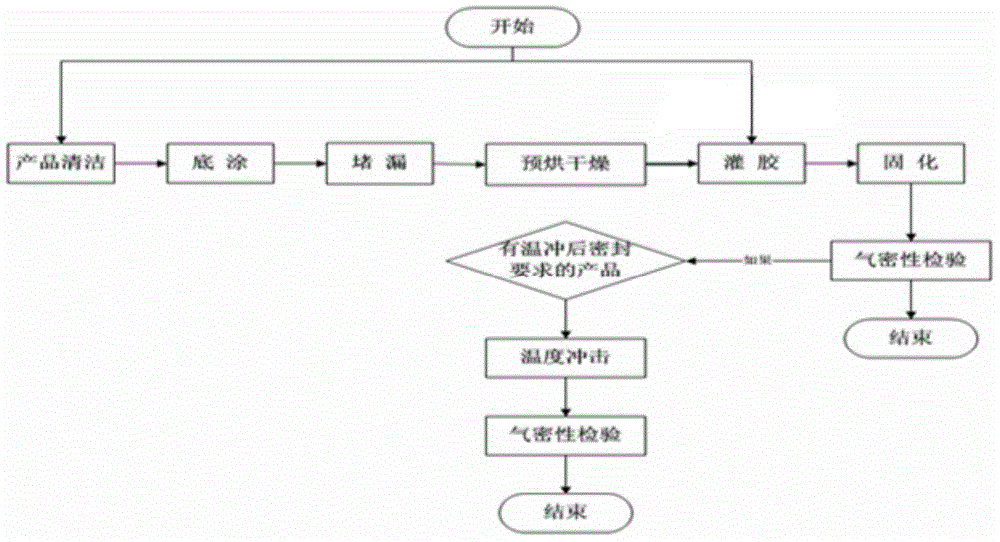

[0042] The present invention proposes a method for potting electrical connector products using polyurethane glue, such as figure 1 As shown, the specific content is as follows:

[0043] (1) Clean the parts to be potted of electrical connector products

[0044] Clean the part of the product to be potted with acetone. Make the bonding and potting parts clean and free from oil, dust and other excess.

[0045] (2) Primer the parts to be potted of electrical connector products

[0046] After the cleaned product is dry, apply the adhesive to the metal-glue bonding part of the product. The primed product is dried at room temperature for 1 hour, and then cured at 100°C-120°C for 1h-2h.

[0047] The specific method of coating the metal and glue bonding part of the product with adhesive is as follows:

[0048] Remove the plating from the bonding surface, then degrease the bonding surface with acetone or isopropanol and allow to dry. If you are using a volatile adhesive, in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com