A method for airtight detection of composite mold

A technology of air tightness detection and detection method, which is applied in liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of fluid, sorting, etc., which can solve the problem of long detection period, high cost, and great influence, etc. problems, to achieve the effect of improving airtight pass rate, eliminating vacuum blockage, and improving high-pressure airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

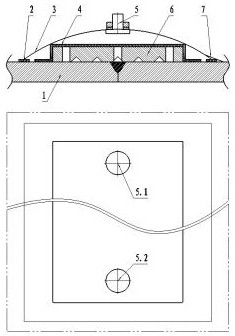

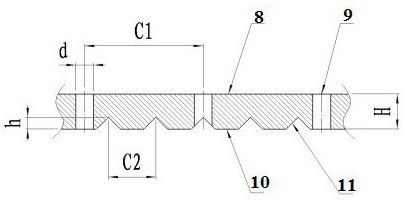

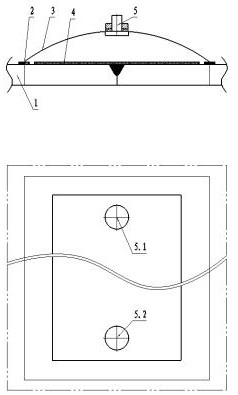

Image

Examples

Embodiment 1

[0044] An airtight detection method for a composite material mold, which uses an airtight detection system for detection, and mainly includes the following steps:

[0045] Step S100: Conduct an airtight test at room temperature and normal pressure; if it is unqualified, check whether there is leakage in the components of the airtight test system and eliminate it;

[0046] Step S200: Carry out the cold pressure test in the autoclave; if it is unqualified, check whether there is leakage in the components of the airtight test system and eliminate it;

[0047] Step S300: Carry out high temperature and high pressure detection in the autoclave; if unqualified, analyze and determine the cause of unqualified according to the pressure, temperature, time graph and data record table; if the following situations occur, the problem existing in the airtight detection system is related to Composite mold 1 has nothing to do: the vacuum degree drops rapidly at a certain point of time and becom...

Embodiment 2

[0050] This embodiment is optimized on the basis of Embodiment 1. If the above situation does not occur in the step S300, the air tightness test is performed again. When the two air tightness test data are all unqualified, and the pressure, temperature and time curves When the maximum deviation in the graph is less than 0.10bar, the cause of failure is ruled out as a problem with the airtight detection system.

[0051] The present invention proposes airtight detection in three stages of room temperature and normal pressure, cold pressure, and high temperature and high pressure. The present invention improves the airtight pass rate of high temperature and high pressure detection through step-by-step detection. Quickly locate the cause of the airtight problem, improve the accuracy of airtight detection, reduce misjudgment, and have good practicability.

[0052] Other parts of this embodiment are the same as those of Embodiment 1, so details are not repeated here.

Embodiment 3

[0054] This embodiment is optimized on the basis of Embodiment 1 or 2. In the step S100, the airtightness detection method at room temperature and normal pressure: the vacuum degree of the vacuum source is less than or equal to -0.93bar, vacuumize, and the vacuum degree of the airtightness detection system is stable The final vacuum degree is less than or equal to the vacuum degree of the vacuum source 0.01 bar. After the vacuum degree of the air tightness detection system is stable for 10 minutes, stop the vacuum source, and the vacuum degree drop value within 10 minutes should be less than or equal to 0.01 bar.

[0055] In the step S200, the cold pressure detection method in the autoclave: at room temperature, the vacuum degree of the vacuum source should be less than or equal to -0.95 bar, pressurize to 6.8 bar, and after 10 minutes of stabilizing the pressure, the vacuum degree of the airtight detection system should be less than or equal to vacuum The source vacuum is 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com