Special air cooler used for marine motor and provided with safety early-warning function

An air cooler, safety warning technology, applied in electrical components, cooling/ventilation devices, electromechanical devices, etc., can solve the problems of easy corrosion of heat exchange tubes, pipe penetration, equipment operation failure, heat exchange medium flowing into the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

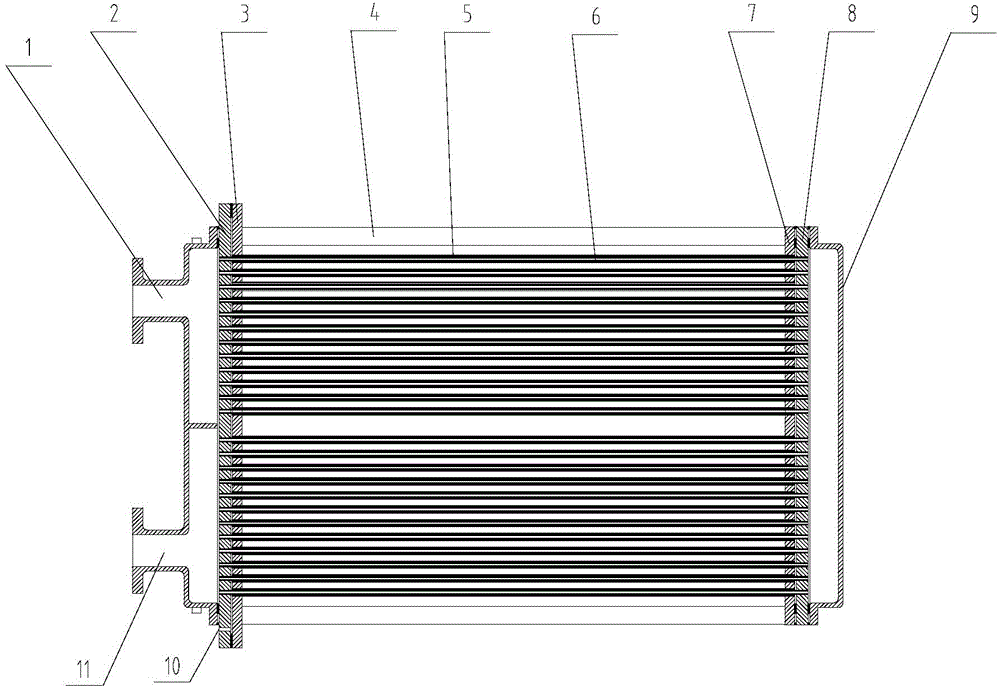

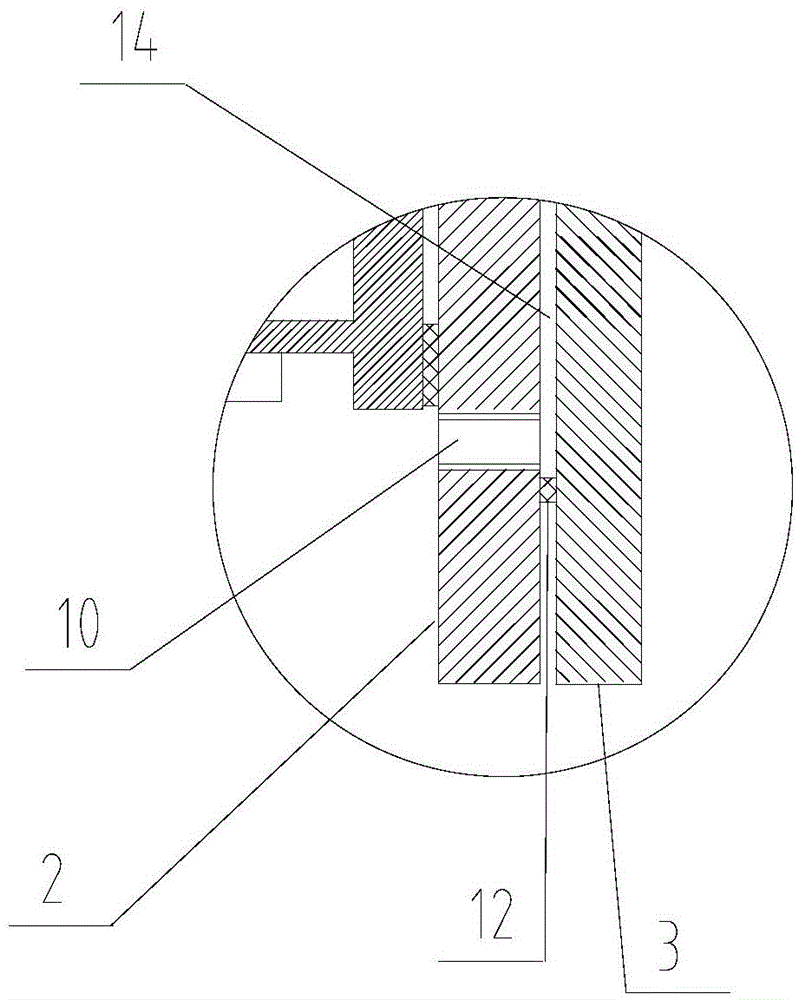

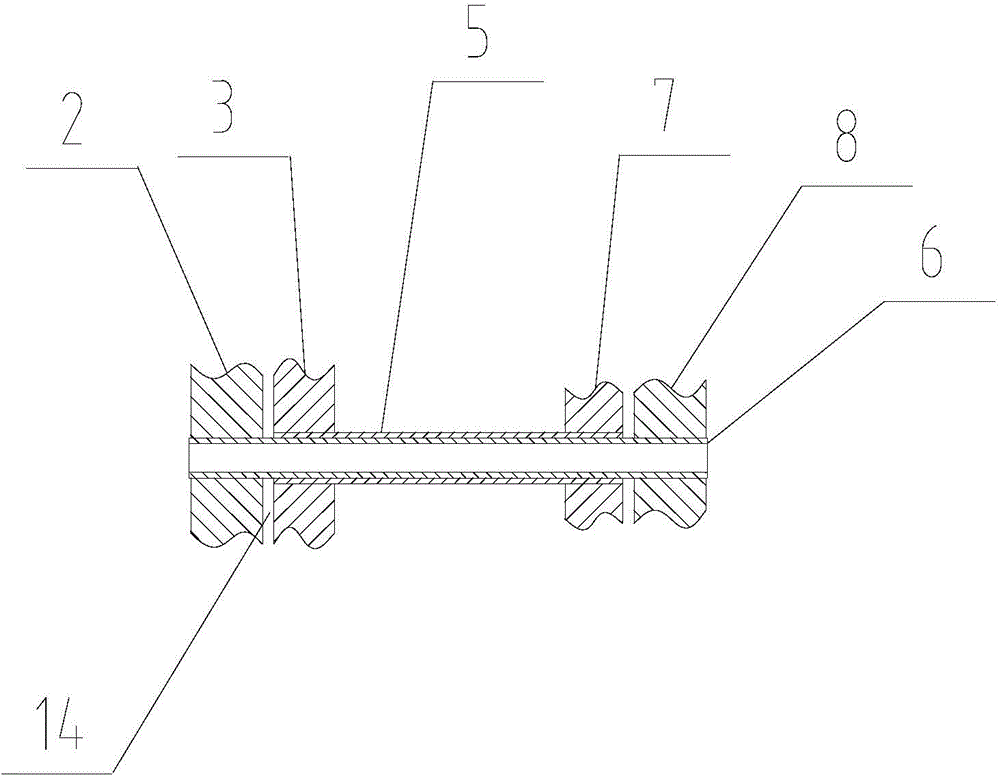

[0016] Such as figure 1 , 2 , 3, and 4, the special air cooler for offshore motors with safety warning function includes water inlet channel 1, water outlet channel 11, return water end cover 9 and guard plate 4; it is characterized in that the offshore motor with safety warning function One end of the dedicated air cooler is provided with a water inlet channel 1 and a water outlet channel 11 and the water inlet channel 1 is arranged above the water outlet channel 11, and one side of the water inlet channel 1 and the water outlet channel 11 is provided with a water side front tube plate 2, the The other side of the water side front tube plate 2 is provided with a wind side front tube plate 3, a flow channel 14 is arranged between the water side front tube plate 2 and the wind side front tube plate 3, and both ends of the flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com