Polyurethane elastomer composite for protecting outer layer of storage tank and preparation method thereof

A polyurethane elastomer and outer layer technology, applied in the field of polyurethane elastomer, can solve the problems of poor weather resistance, poor cushioning effect, poor adhesion between the product and the storage tank, etc., achieve scientific and reasonable preparation method, prolong service life, avoid easy rusty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

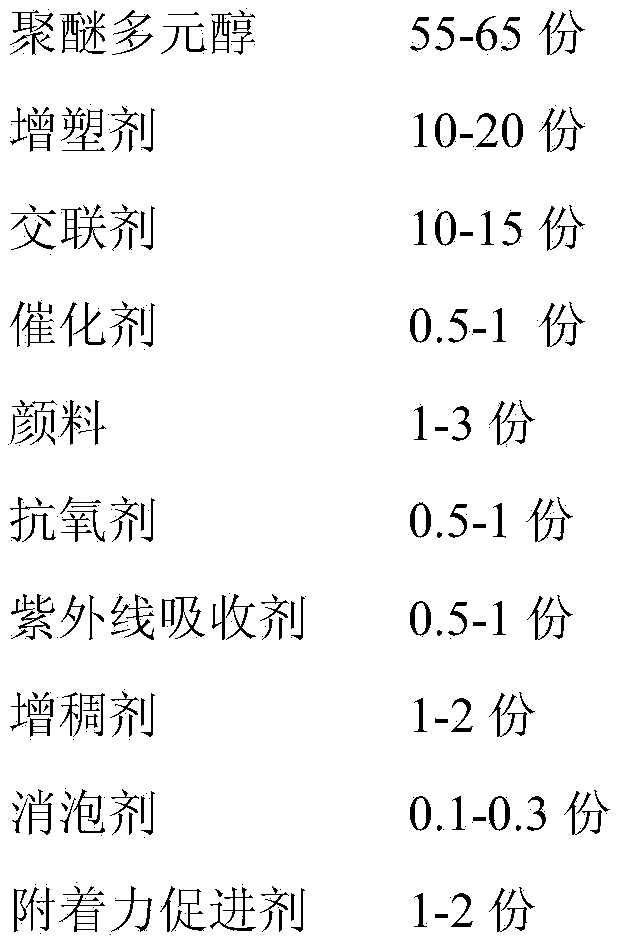

Method used

Image

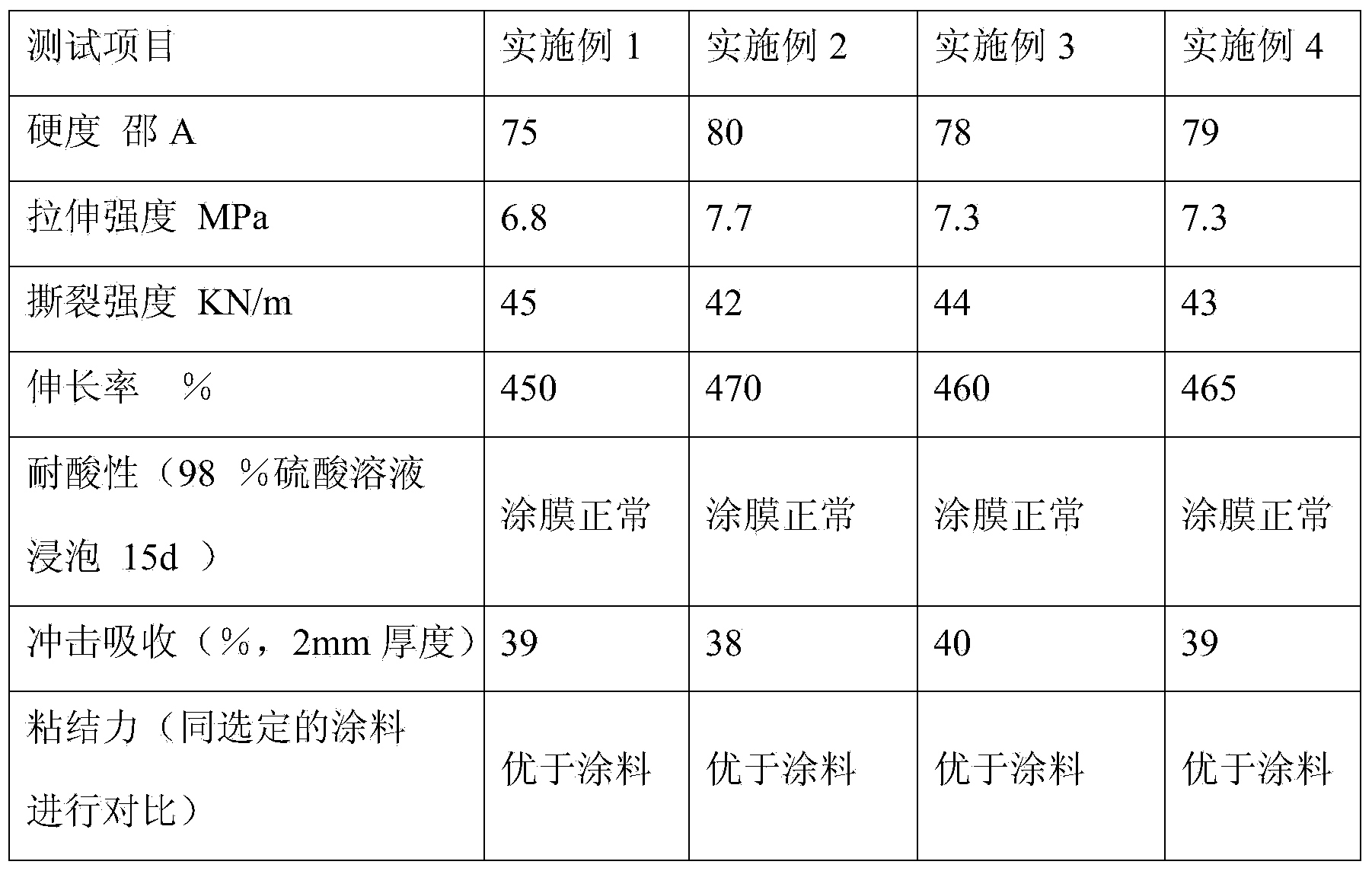

Examples

Embodiment 1

[0035] (1) Prepare 1000 grams of component A: Add 400 grams of silane-modified polyether polyol 2-chloroethylamine hydrochloride 870-24-6 octamethylcyclotetrasilyl ether, polyether polyol ( Ethylenediamine as the starter, average functionality 4, molecular weight 2600) 150g, acetyl trioctyl citrate 97g, acetyl tributyl citrate 100g, 4,4'-methylenebis(2,6- 150 grams of diethyl)aniline, 10 grams of bis(3-dimethylaminopropyl)amino-2-propanol, 30 grams of iron oxide red, tris(2,4-di-tert-butylphenyl) phosphite 10 grams, 10 grams of 2-(2-hydroxy-3-dodecyl-5-methyl) benzotriazole, 20 grams of modified hydrogenated castor oil, 20 grams of anilinomethyltriethoxysilane, stirring After grinding for 20 minutes, vacuum dehydrate at a temperature of 90°C and a vacuum degree of 0.09MPa for 3 hours, detect the mass fraction of moisture in the material, the mass fraction of moisture is 0.1%, cool down to 30°C, add 553 grams of BYK-A5, and stir for 10 minutes After that, it can be loaded into...

Embodiment 2

[0039] (1) Prepare 1000 grams of component A: Add 400 grams of silane-modified polyether polyol 2-chloroethylamine hydrochloride 870-24-6 octamethylcyclotetrasilyl ether, polyether polyol ( Ethylenediamine as the initiator, average functionality 4, molecular weight 2400) 250g, acetyl tributyl citrate 200g, 3,5-dimethylthiotoluenediamine 104g, bis(3-dimethylammonia Propyl) amino-2-propanol 5 g, iron oxide red 10 g, tris(2,4-di-tert-butylphenyl) phosphite 5 g, 2-(2-hydroxy-3-dodecyl -5-methyl) benzotriazole 5 grams, modified hydrogenated castor oil 10 grams, anilinomethyltriethoxysilane 10 grams, stirred for 30 minutes, after grinding, at a temperature of 100 ° C and a vacuum of 0.1 MPa Vacuum dehydration for 1 hour, detect the mass fraction of moisture in the material, the mass fraction of moisture is 0.08%, cool down to 50°C, add BYK-A5551 g, stir for 20 minutes and then fill the barrel;

[0040] (2) Prepare 1000 grams of component B: add 400 grams of 2-chloroethylamine hydroch...

Embodiment 3

[0043] (1) Prepare 1000 grams of component A: Add 447 grams of silane-modified polyether polyol 2-chloroethylamine hydrochloride 870-24-6 octamethylcyclotetrasilyl ether, polyether polyol ( Ethylenediamine as the starter, average functionality 4, molecular weight 2500) 200g, acetyl trioctyl citrate 100g, 4,4'-methylenebis(2,6-diethyl)aniline 100g, 50g of 3,5-dimethylthiotoluenediamine, 5 grams of bis(3-dimethylaminopropyl)amino-2-propanol, 5 grams of Bicat8MA①, 30 grams of iron oxide red, tris(2,4-phosphite Di-tert-butylphenyl) ester 10 grams, 2-(2-hydroxy-3-dodecyl-5-methyl) benzotriazole 10 grams, modified hydrogenated castor oil 20 grams, anilinomethyl tri 20 grams of ethoxysilane, stirred for 25 minutes, after grinding, vacuum dehydrated at a temperature of 95°C and a vacuum degree of 0.095MPa for 2 hours, detected the moisture content in the material, and the moisture content was 0.07%, cooled to 45°C, and added BYK -A5553g, can be filled into barrels after stirring for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com