Microwave drying of ceramic honeycomb logs using a customizable cover

A microwave drying and ceramic honeycomb technology, which is applied in the drying of ceramic products, ceramic molding machines, progressive dryers, etc., can solve the problems that the material section does not meet the shape regulations, and the shape of the material section is changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will now be described in detail with reference to examples shown in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0046] The claims set forth below are incorporated into and constitute a part of this Detailed Description.

[0047] Any reference cited herein is incorporated by reference in its entirety.

[0048] In the following description, the word "cover" is used to describe wraps and rigid covers or shields generally. Accordingly, a cover is sometimes referred to as a wrap and sometimes as a rigid cover, depending on the example embodiment of the cover in question.

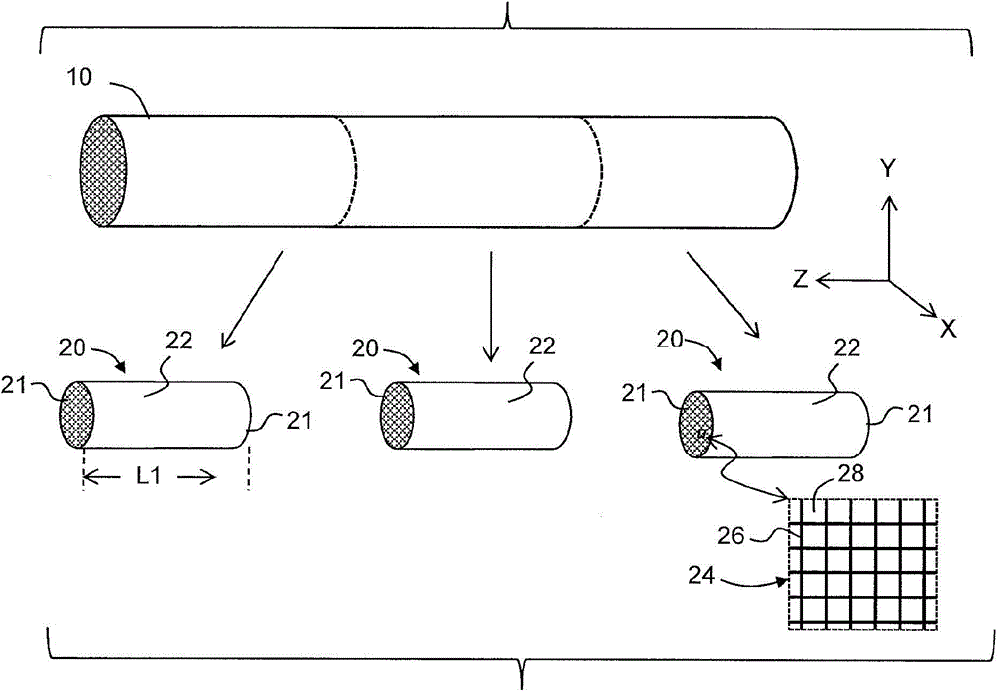

[0049] figure 1 is a perspective view of an idealized ceramic extrudate 10 cut into segments or billets 20, also known as pottery blanks. Log 20 has opposing ends 21 and an axial length L1 which may be, for example, about 3 feet, and may have substantially any rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com