A non-injury automatic pig toilet

A pig toilet and automatic cleaning technology, which is applied in animal houses, applications, animal husbandry, etc., can solve the problems of rising sickness rate of pigs, pig injury, and labor-intensive manual cleaning of feces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

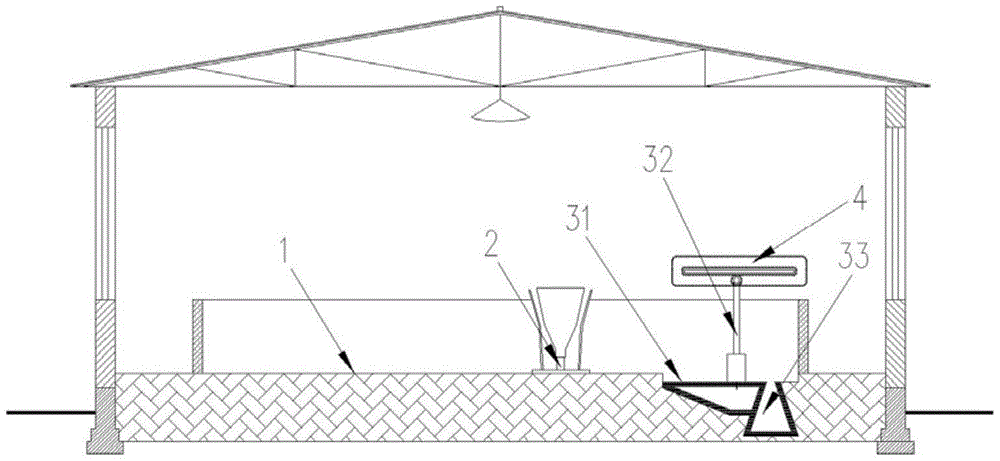

[0052] Embodiment 1: Single row pigsty

[0053] Such as figure 1As shown, the length-to-width ratio of the pigsty is 1:1.5 to 1:2, and the specific length and width of the pigsty can be determined in combination with the scale of group breeding of pigs. The pigsty is divided into a lying area 1 and a defecation area 3. The lying area 1 and the defecation area 3 are respectively on both sides of the pigsty. The defecation area 3 is lower than the lying area 1. In this embodiment, the defecation area 3 is lower than the lying area. 1 is 100mm lower, in order to enhance the pig's sense of defecation area; feeding area 2 is distributed on the side wall of the pigsty, and adopts an automatic feeding device. Through the positioning of the three areas in the pigsty, the "three-point positioning" habit of the pig can be satisfied, thereby enhancing the sense of the pig's defecation area.

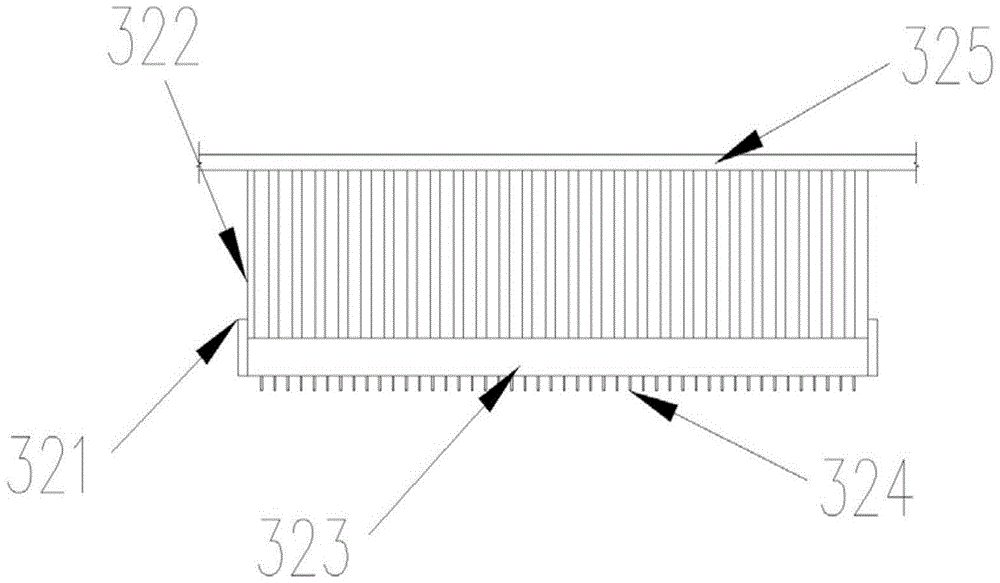

[0054] Such as figure 2 As shown, the non-injury automatic excrement-cleaning pig toilet is ...

Embodiment 2

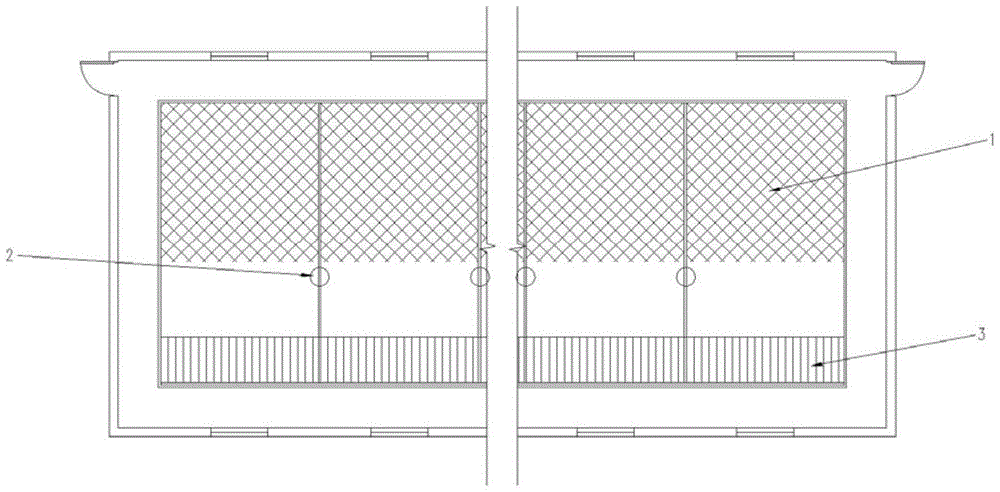

[0059] Embodiment 2: Double row pigsty

[0060] Such as Figure 7-10 As shown, the non-injury automatic manure-cleaning pig latrine of the double-row pigsty is basically the same in structure as the non-injury automatic manure-cleaning pig latrine of the single-row pigsty. A pigsty is respectively arranged on both sides of the pigsty, so the pigsty on both sides share a manure ditch 332, and other pig latrine structures of the double row pigsty are all arranged symmetrically along the dung ditch 332 simultaneously.

[0061] Double row pigsty, including one or more groups of pigsty arranged in pairs, each pigsty includes lying area 1, feeding area 2 and defecation area 3, lying area 1 and defecating area 3 respectively in each On both sides of each pigsty, the defecation area 3 is lower than the lying area 1, the feeding area 2 is distributed on the side wall of each pigsty, and the defecation area 3 of each pigsty is arranged in the middle of each group of pigsty next to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com