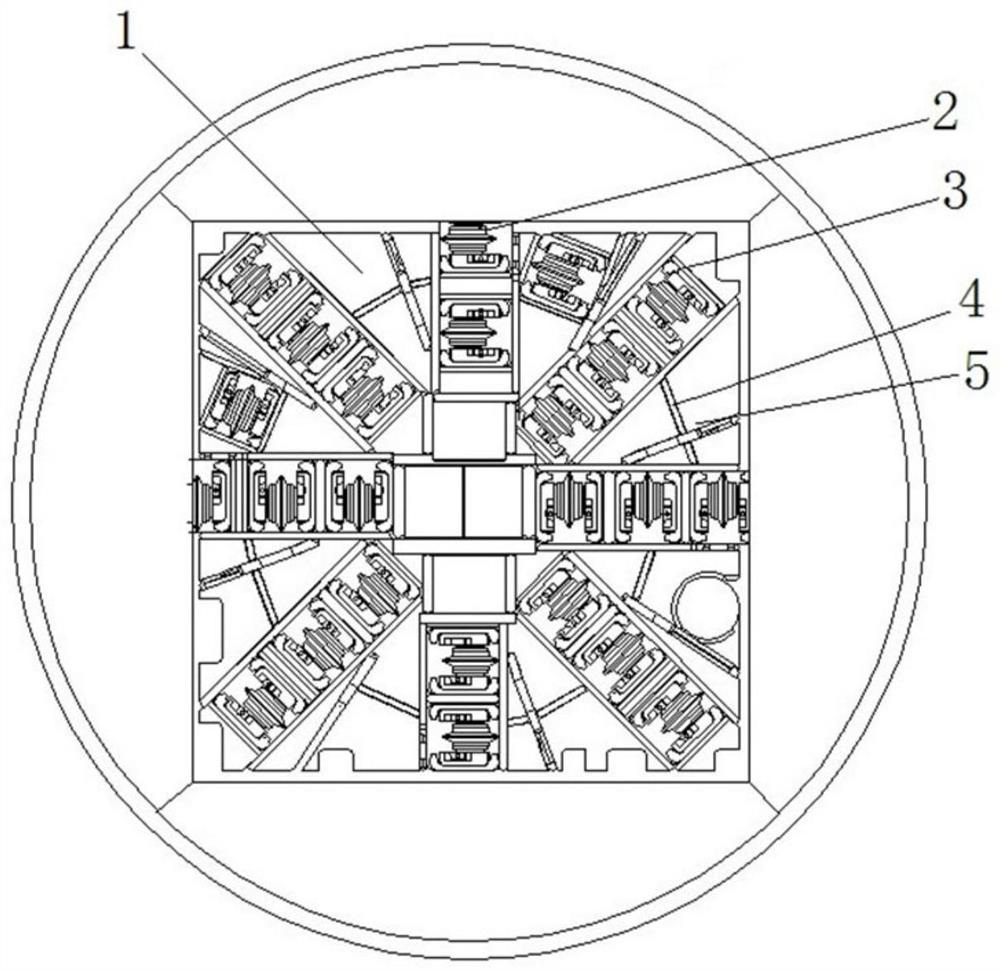

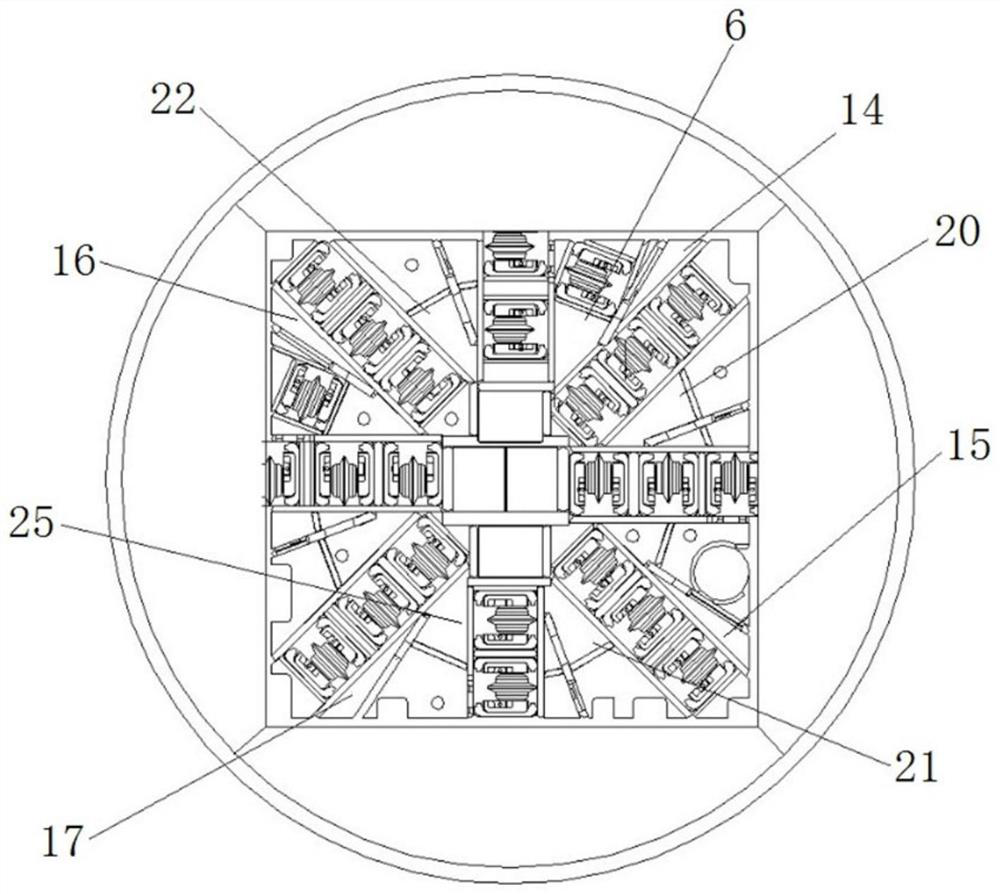

Heading machine cutter head and heading machine

A technology of roadheader and cutter head, which is applied in mining equipment, tunnels, earthwork drilling and mining, etc. It can solve the problems that the structural strength has not been improved and the implementation is difficult, so as to enhance the friction function, ensure the structural strength, and reduce the vibration of the structure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0090] The specific embodiment 2 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the damper is fixed in the corresponding opening cavity by welding. In this embodiment, threaded holes are formed on the side walls of the damper, and fixing holes corresponding to the threaded holes on the damper are formed on the ribs of the corresponding openings. Screws fix the dampers in the corresponding openings.

specific Embodiment 3

[0091] The specific embodiment 3 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the sealing cover is fixed in the corresponding particle filling hole by screws. In this embodiment, the sealing cover is a screw plug, and the corresponding particle filling hole is a threaded hole.

[0092] The specific embodiment 4 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the volume of the damping particles in the box accounts for 70%-90% of the cavity of the box. In this embodiment, the volume of the damping particles in the box accounts for less than 70% of the cavity of the box, such as 65%.

specific Embodiment 5

[0093] The specific embodiment 5 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the mass ratio of damping particles of different sizes in the damper ranges from 1:1 to 1:1.5. In this embodiment, the mass ratio of the damping particles of different sizes in the damper is greater than 1:1 to 1:1.5, and is 1:1 to 1:1.6. Of course, in other embodiments, the damping particles of different sizes in the damper The mass ratio of the particles can also range from other ranges of values greater than 1:1 to 1:1.5.

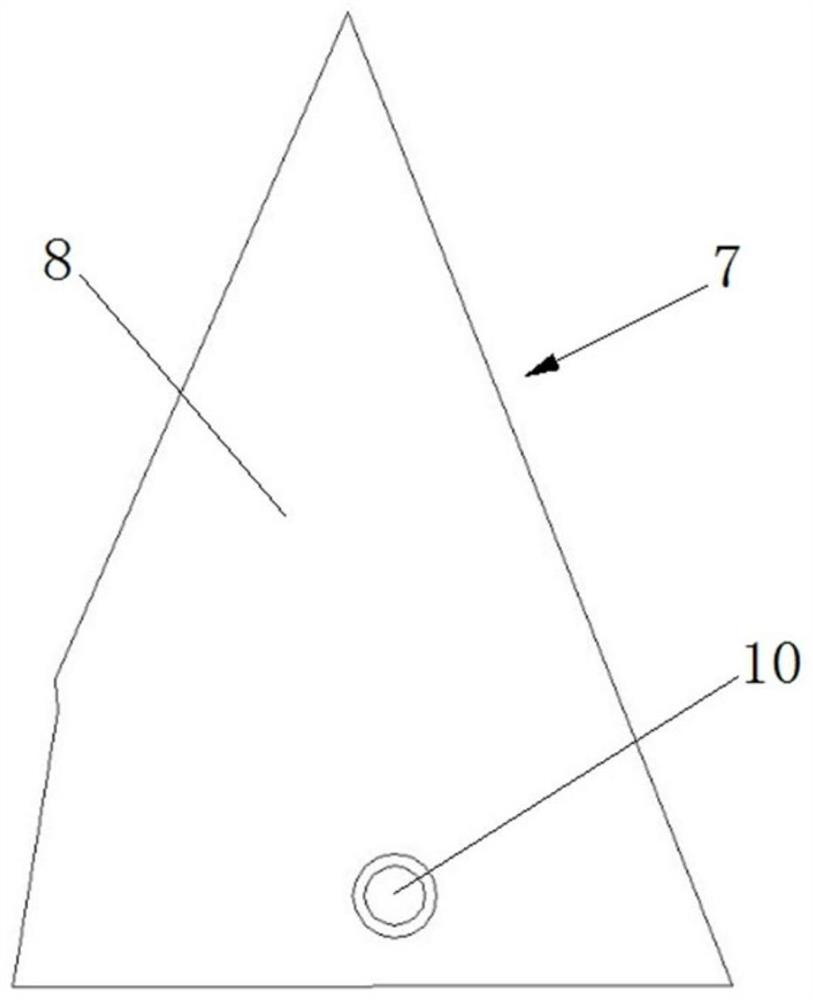

[0094] The embodiment of the roadheader cutter head provided by the present invention:

[0095]The structure and working principle of the cutter head of the roadheader in the present invention are the same as those of the cutter head of the above-mentioned roadheader, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com