Solid acid catalyst, preparation method and application

A solid acid catalyst and catalyst technology, applied in chemical recovery, organic chemistry, etc., can solve the problems of low utilization rate of active sites, difficulty in bare leakage, etc., and achieve the effects of cycle stability, high utilization rate and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of protonated zirconium hydrogen phosphate nanosheets

[0031] Weigh 0.3 g of zirconium hydrogen phosphate and disperse it in 20 mL of deionized water, ultrasonically stir for 3 hours, then add 10 mL of 0.1 mol / L 1-propylamine, and ultrasonically treat for 3 hours in an ice bath to obtain exfoliated zirconium hydrogen phosphate nanosheets. Then drop 10mL of 0.1mol / L HCl into it, and wash by centrifugation until there is no Cl in the filtrate. - In the presence of protonated zirconium hydrogen phosphate nanosheets.

[0032] (2) Preparation of solid acid catalyst

[0033] Using ion exchange method, 0.3655g Zn(AC) 2 Dissolve in 50mL deionized water, add the above-mentioned protonated zirconium hydrogen phosphate nanosheets, wherein Zn(AC) 2 The molar ratio of zinc ions to zirconium hydrogen phosphate is 2:1. Stir and sonicate for 2 hours, then reflux at 80°C for 12 hours. After the reaction is finished, let it stand for 12 hours, set the centrifugal sp...

Embodiment 2

[0035] In this example, the ion exchange method is adopted, and the molar ratio of lanthanum ion to zirconium hydrogen phosphate is 5:1, and 1.7598gCl 3 h 12 LaO 6 Dissolve in 50 mL of deionized water, then add 0.3 g of protonated zirconium hydrogen phosphate nanosheets, and stir at 50° C. for 24 hours. Other steps are the same as in Example 1 to prepare a solid acid catalyst.

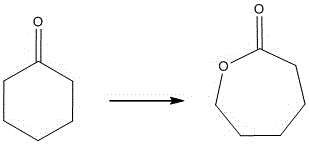

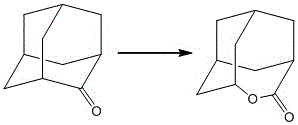

[0036] When the solid acid catalyst prepared in Examples 1-2 is applied to the Baeyer-Villiger oxidation reaction, the specific method can be: weigh 0.05g of solid acid, add 0.3951g of cyclohexanone, 2.2391g of 30wt.% hydrogen peroxide, at 70°C React for 12 hours, the reaction chemical formula is as figure 1 shown. After the reaction, the catalyst was centrifugally separated, and the catalyst was washed with hydrogen peroxide to carry out the next round of reaction. A total of 5 catalytic reactions were performed. After the reaction solution was filtered, the gas-mass spectrometer was used to analyz...

Embodiment 3

[0038] (1) Preparation of protonated zirconium hydrogen phosphate nanosheets

[0039] Weighed 1.2 g of zirconium hydrogen phosphate and dispersed it in 50 mL of deionized water, stirred it ultrasonically for 5 hours, then added 4 mL of 1 mol / L 1-propylamine, and treated it ultrasonically for 5 hours in an ice bath to obtain exfoliated zirconium hydrogen phosphate nanosheets. Then drop 4 mL of 1 mol / L HCl into it, and wash by centrifugation until there is no Cl in the filtrate. - In the presence of protonated zirconium hydrogen phosphate nanosheets.

[0040] (2) Preparation of solid acid catalyst

[0041] In this example, the ion exchange method is adopted, and the molar ratio of yttrium ion to zirconium hydrogen phosphate is 3:1, and 1.7684gC 2 h 3 o 2Y was dissolved in 60 mL of deionized water, and then 1.2 g of the above-mentioned protonated zirconium hydrogen phosphate nanosheets were added, and stirred at 90° C. for 12 hours. After the reaction was completed, let it s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com