Lift-on-lift-off type otter board goods shelf and manufacturing method thereof

A manufacturing method and hoisting technology, applied in the field of machinery, can solve the problems of loss and hard to find, and achieve the effects of high production efficiency, simple manufacturing process and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

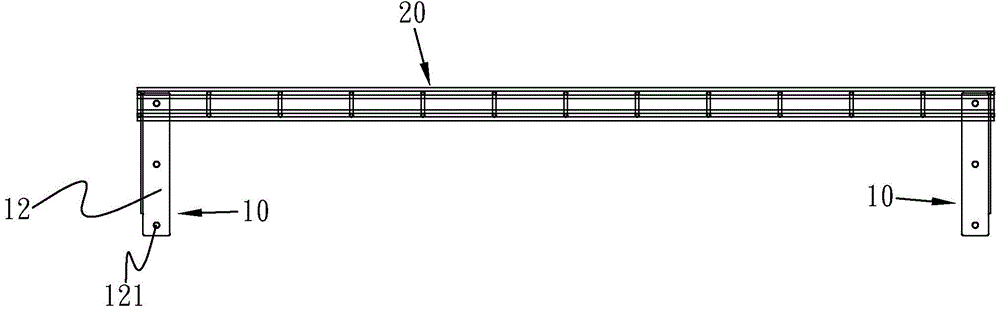

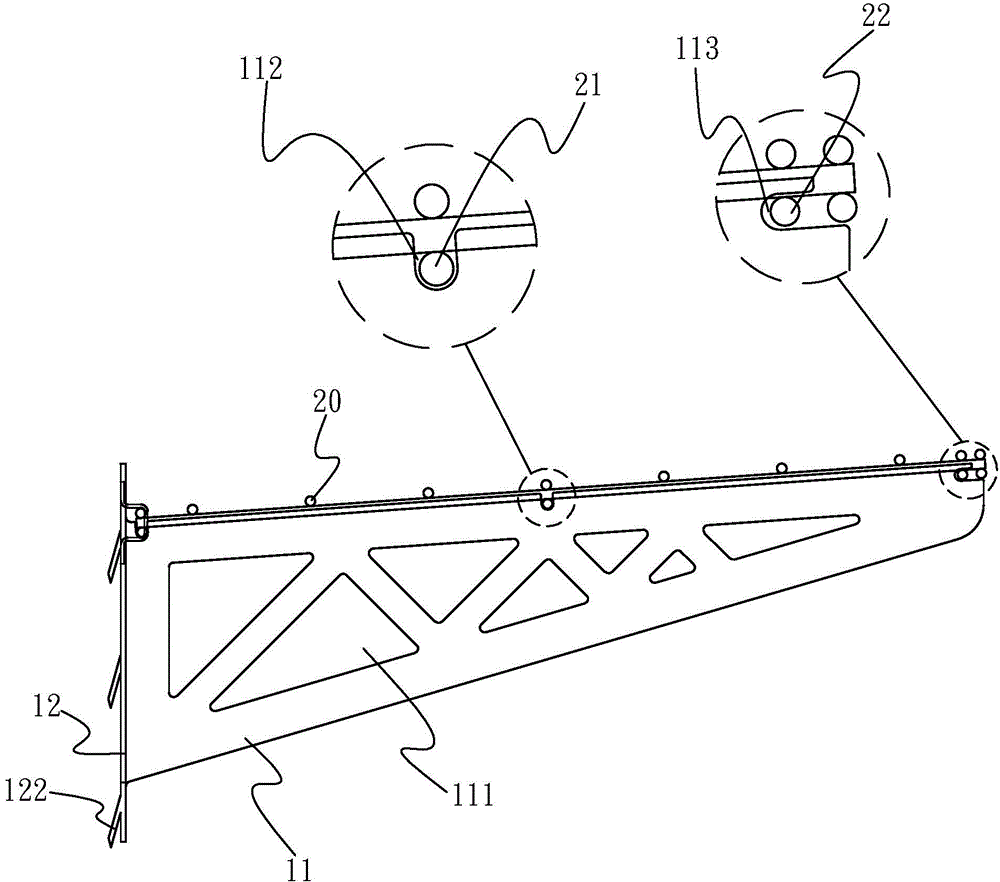

[0028] see figure 1 and figure 2 According to the present invention, the hoisting mesh shelf includes at least two parallel supports 10 and an object storage unit 20 fixed on the top of the supports 10 . The hoisting mesh shelf is detachably arranged on the wall or a large shelf (not shown in the figure) through the support member 10 . The large shelf includes vertically arranged columns, crossbeams horizontally erected on the columns and laminates arranged on the crossbeams.

[0029] read on figure 1 and figure 2 , the supporting member 10 has a plate-shaped supporting portion 11 and a connecting portion 12 connected to one end of the supporting portion 11 . Several reinforcing holes 111 with different areas are op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com