On-line identification method for plating clamps

An electroplating fixture and online identification technology, applied in the field of online identification, can solve the problems of reducing production efficiency, unable to detect in time by staff, unable to code and identify the fixture, etc., to ensure stable operation, excellent conductivity, and realize automatic management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

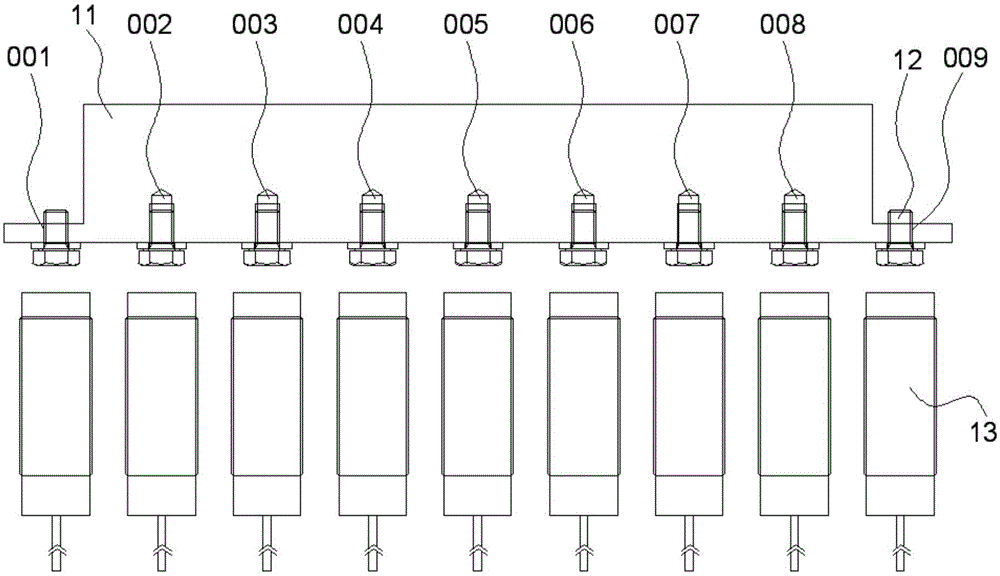

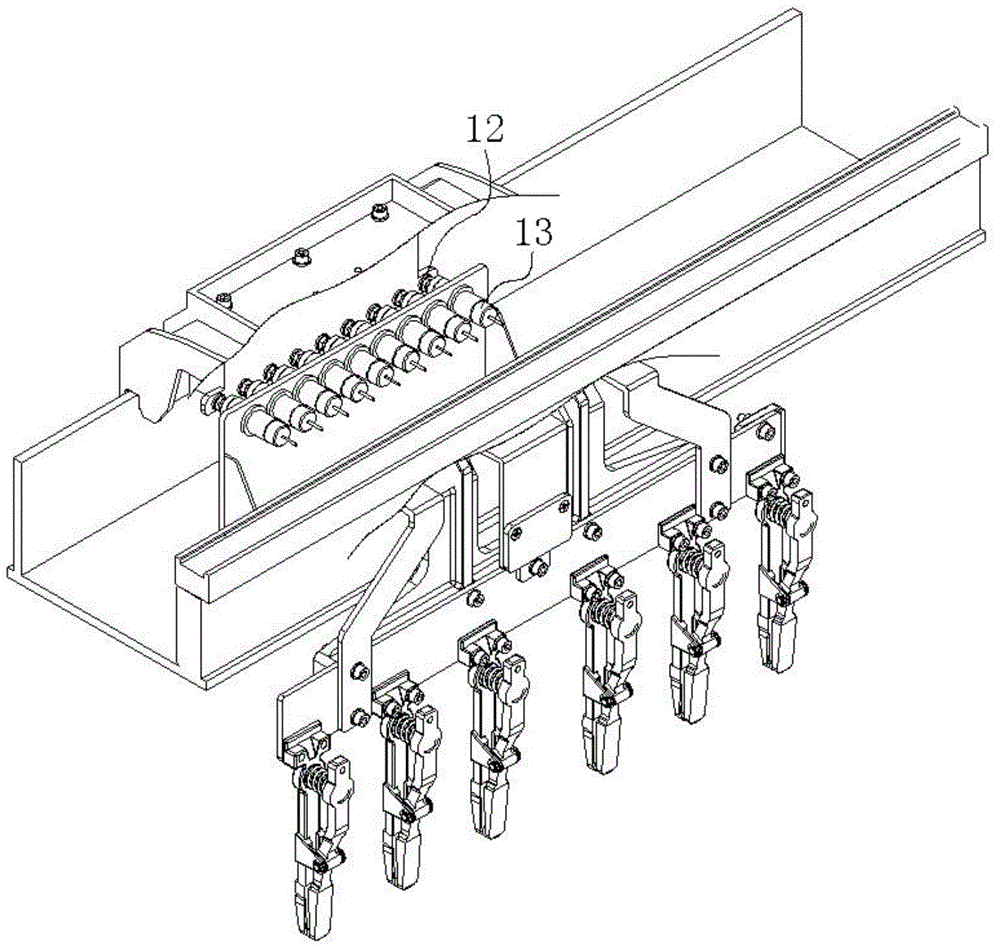

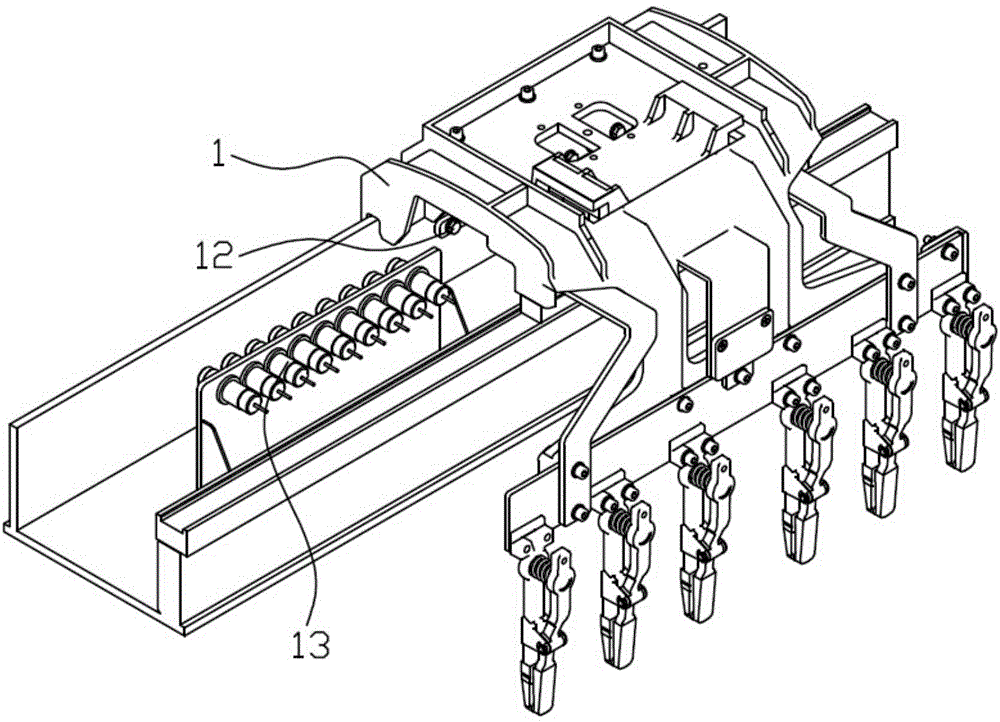

[0023] Such as Figure 1-3 As shown, an electroplating fixture online identification method of the present invention, the method is: (1) set nine screw holes 001-009 on the fixture breeding block 11 of the electroplating fixture 1; (2) set the screw holes on the screw holes At least one corresponding position is provided with an induction screw 12; (3) An induction device, such as a proximity switch 13, is provided on the outside of the screw hole one by one, and a gap is left between the proximity switch 13 and the induction screw 12 for induction. Screw 12, so as to output the signal; (4) The output signal is compared with the data pre-stored in the fixture operating system, and the number corresponding to each fixture is sequentially obtained through binary calculation, so as to realize the code recognition of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com