Improved post-pouring strip advanced water-stopping construction method

A construction method and post-casting belt technology, which are applied in hydraulic engineering, artificial islands, underwater structures, etc., can solve problems such as rare disclosure of improved technology, easy deformation of filling materials, position deviation, etc., and achieve multi-operation space and optimization. The effect of using the on-site construction site and the water-stop function to improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

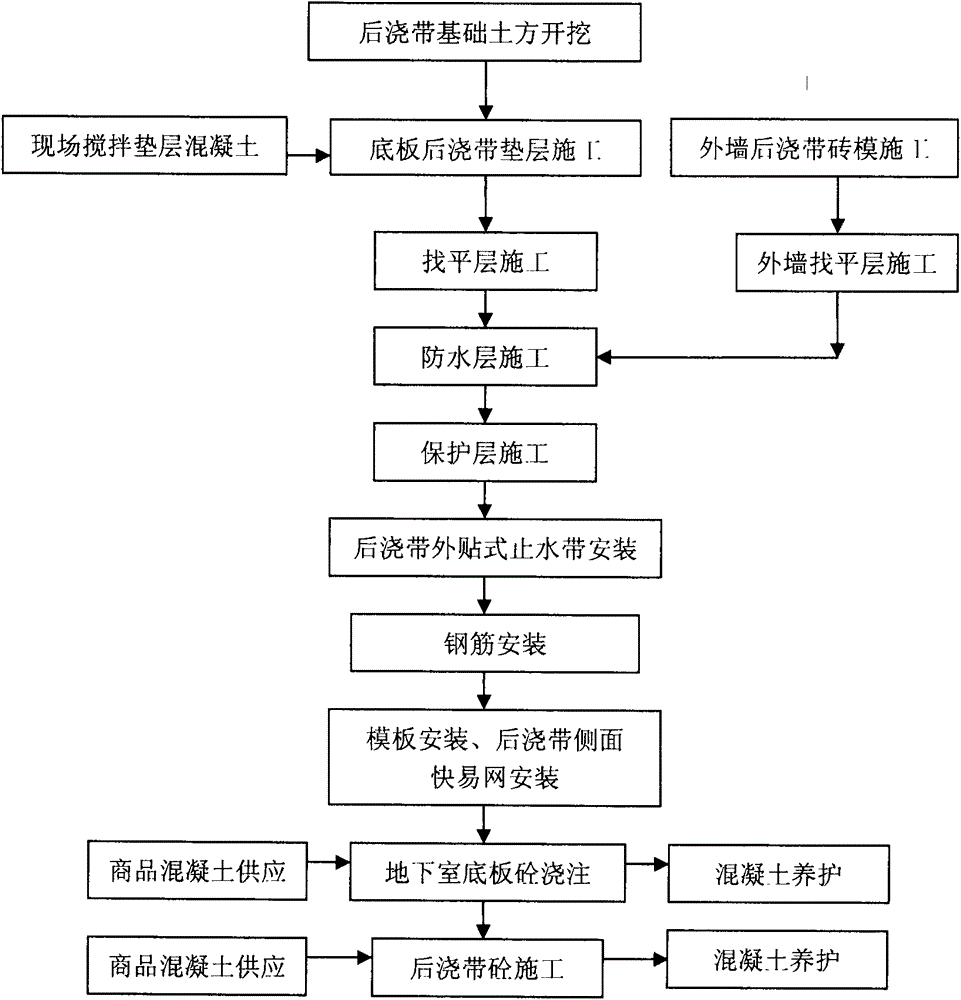

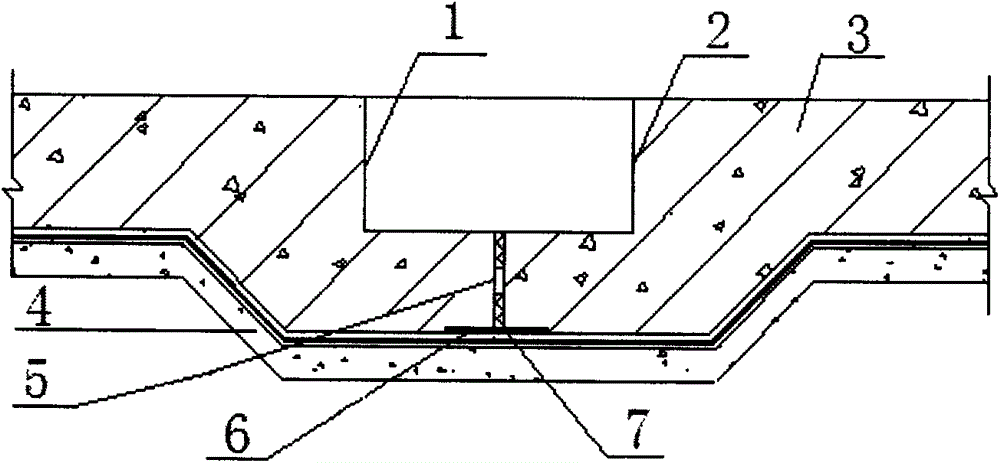

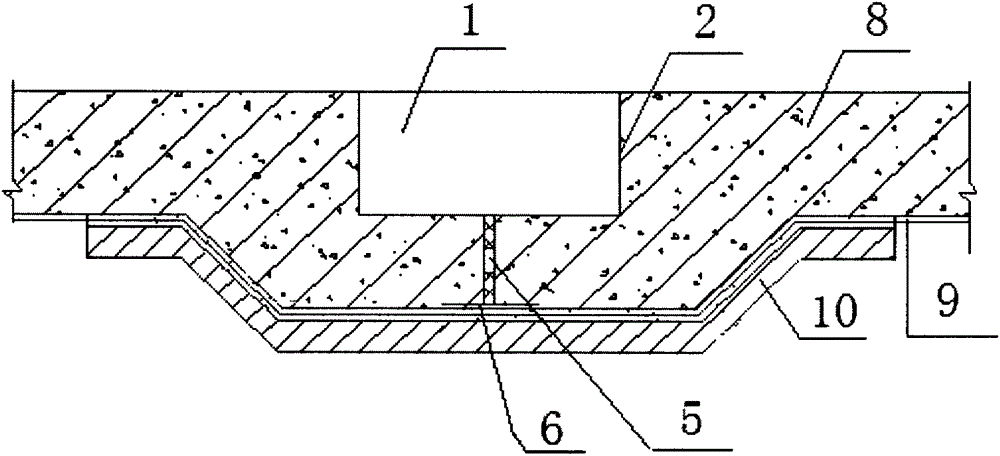

[0030] Example: as attached figure 1 As shown, the steps of the construction method include earthwork excavation of the foundation of the post-pouring belt, construction of the bottom plate and the cushion layer of the post-pouring belt, construction of the leveling layer, construction of the waterproof layer, construction of the protective layer, installation of the post-pouring belt and the external waterstop, and reinforcement Installation, formwork installation, post-pouring belt side quick and easy net installation, basement bottom slab concrete pouring, post-pouring concrete construction; among them, site mixing cushion concrete back bottom slab post-pouring belt cushion construction; external wall post-pouring belt and brick mold After construction, the leveling layer construction of the exterior wall is carried out, and then the waterproof layer construction is carried out; the commercial concrete supply is subjected to concrete curing after the concrete pouring of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Lap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com