Bionic excavator bucket tooth

An excavator bucket tooth and bionic technology, which is applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problems of reduced cutting capacity, bucket tooth wear, etc., and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

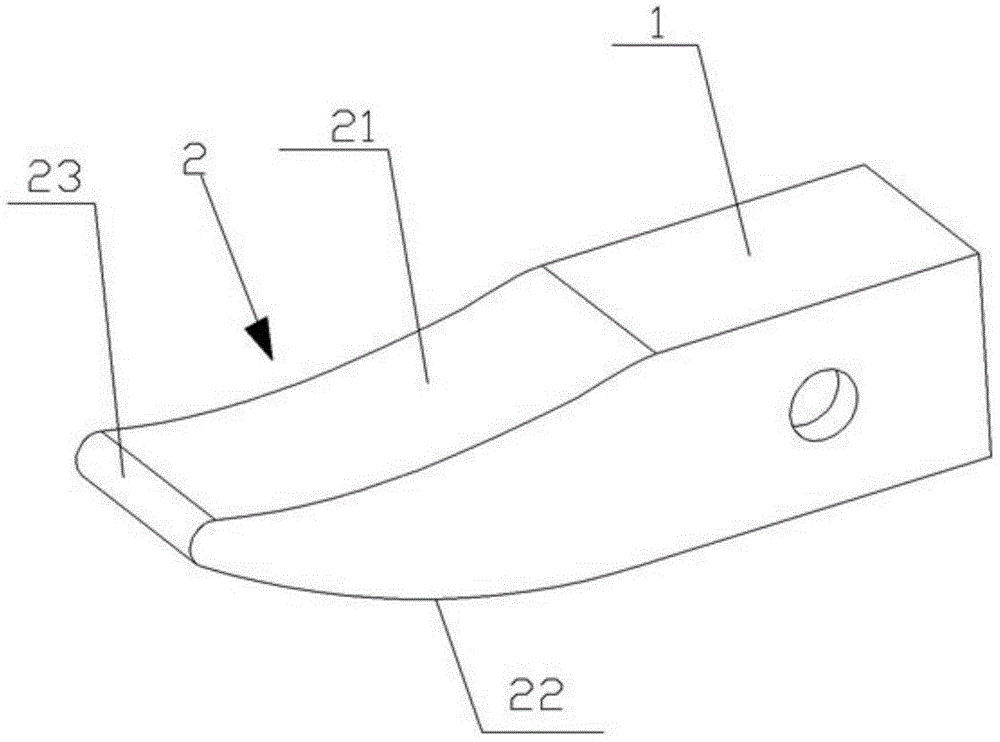

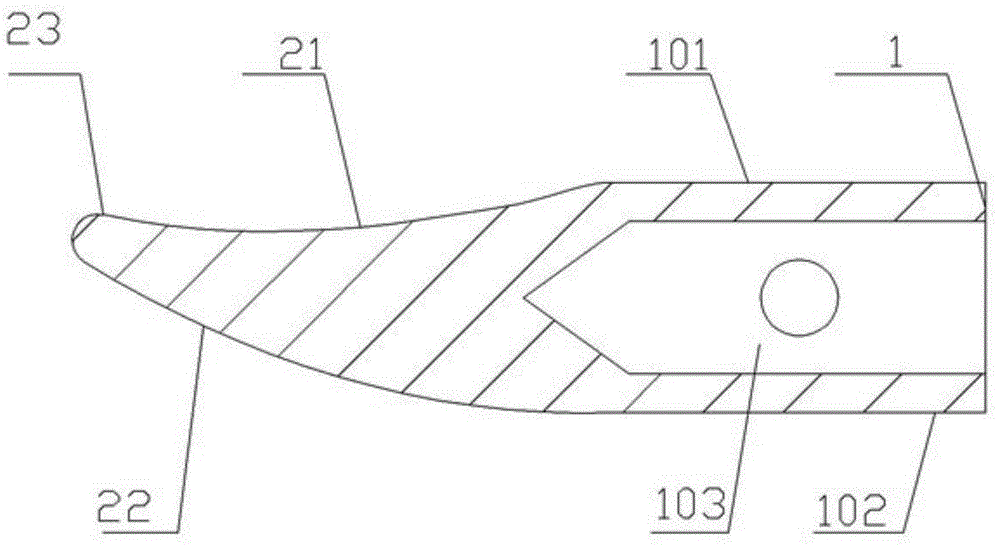

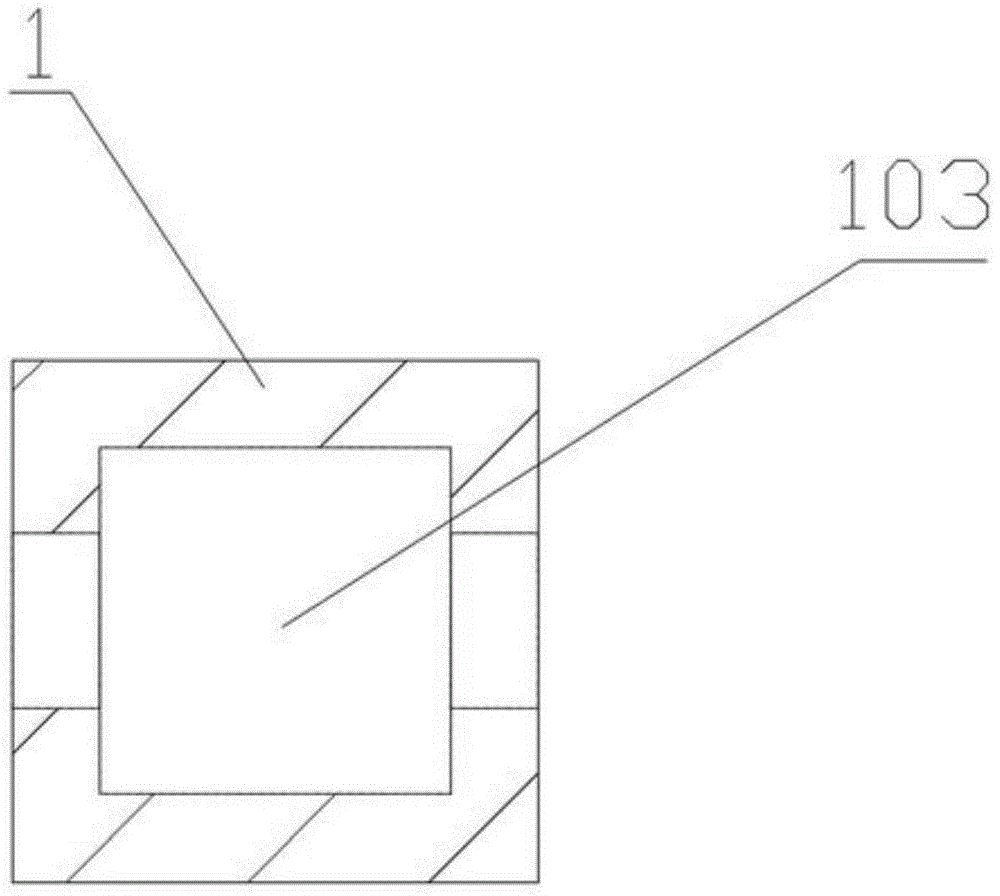

[0012] see figure 1 , figure 2 and image 3 As shown, this embodiment is composed of the installation end (1) and the soil contact end 2, the soil contact end 2 is located at the front of the installation end (1), and the installation end 1 is provided with an upper end surface (101) and a lower end surface (102) and concave cavity (103), the soil contact end 2 has an inner soil contact surface (21), an outer soil contact surface (22) and a front end soil contact surface (23), and the front end soil contact surface (23) is an arc surface, and the circle The radius of the arc is 3-8 mm, the inner soil contact surface (21) and the outer soil contact surface (22) are arranged oppositely, and the starting end of the contour curve of the inner soil contact surface (21) is tangent to the upper end of the arc of the front soil contact surface (23) , the end of the contour curve of the inner soil-contacting surface (21) is tangent to the upper end surface (101) of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com