Design method of pre-posed diffuser controlled based on total pressure loss

A technology of total pressure loss and design method, which is applied in the direction of combustion method, combustion equipment, lighting and heating equipment, etc., to achieve high flow performance, clear design ideas and good engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, that is, the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] The present invention comprises the following steps:

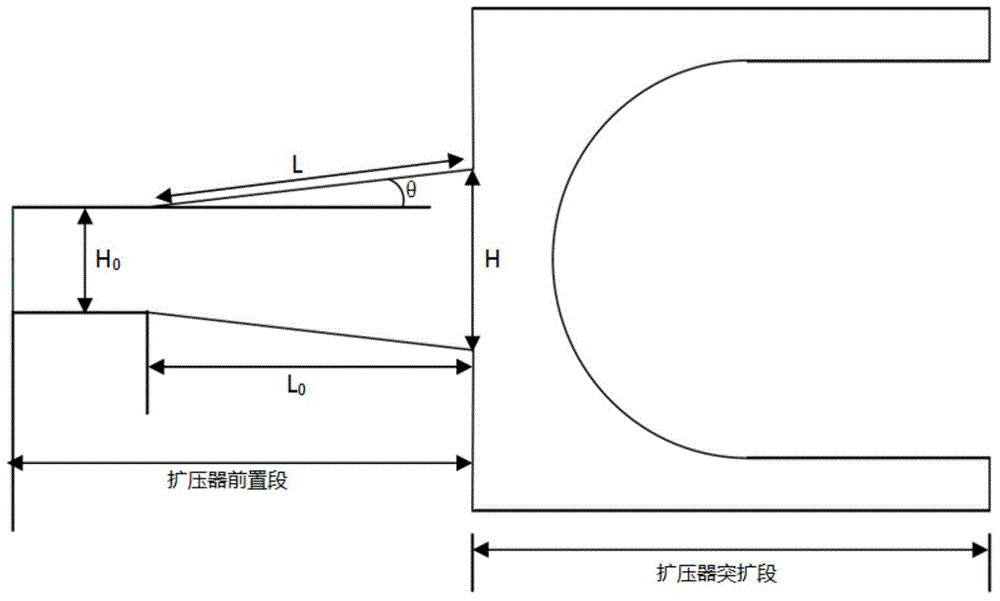

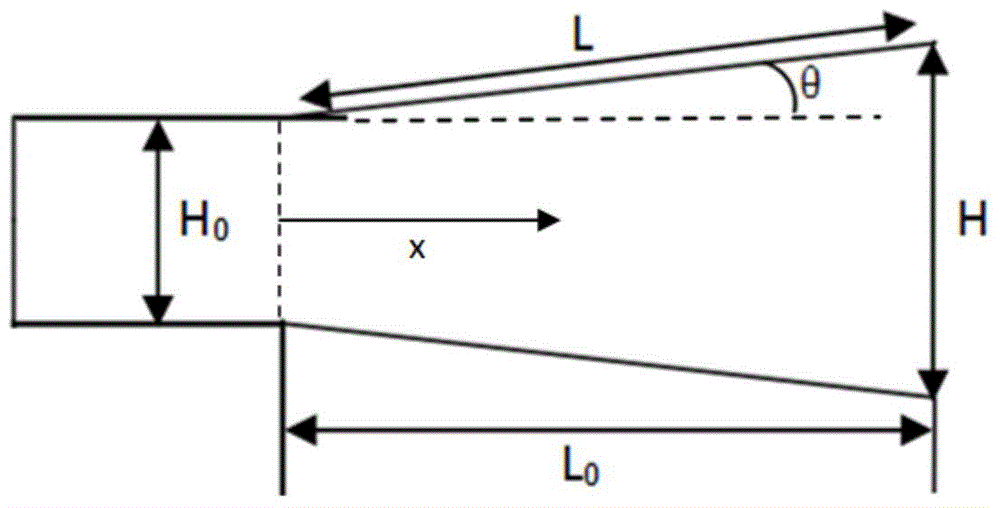

[0025] 1) Determine the original size. Such as figure 1 As shown, the prediffuser inlet size H is determined according to the compressor outlet size 0 , determine the length L of the prediffuser according to the overall design length requirements of the gas turbine 0 , in subsequent designs H 0 and L 0 constant;

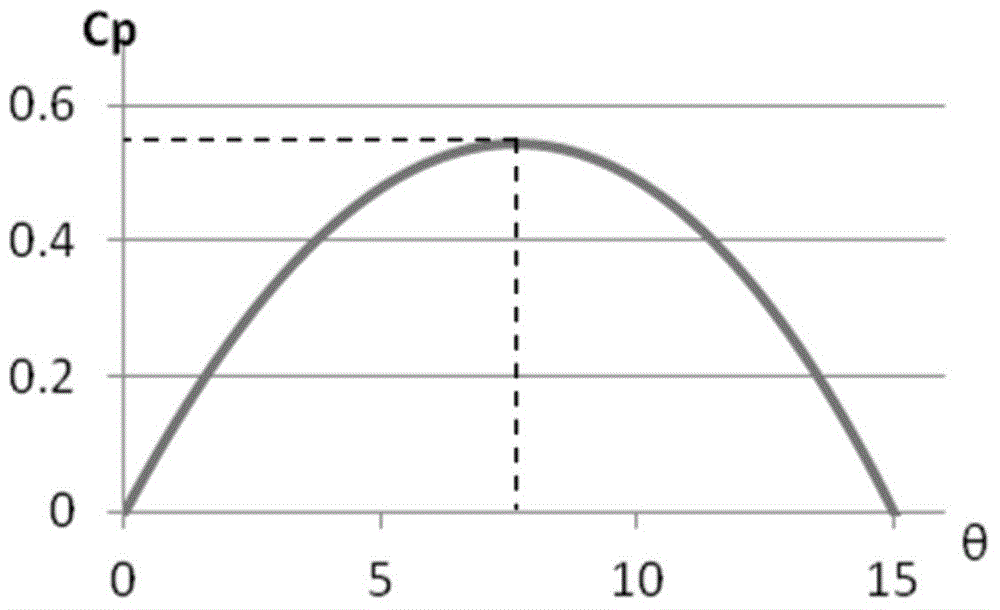

[0026] 2) Determine the critical expansion angle θ 0 . According to multiple sets of calculation and experimental comparison data, the present invention proposes the critical sudden expansion angle θ 0 The prediction formula ① is where C P is the static pressure recovery coefficient, H 0 is the inlet si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com