Protecting device for extra-high pressure engineering foundation bolt

A technology for anchor bolts and protection devices, which is applied in the direction of bolts, nuts, threaded fasteners, etc., can solve the problems of affecting the progress of electric power construction, inconvenient installation of iron towers, and damage to anchor bolts, so as to avoid economic losses and prevent external forces damage, the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

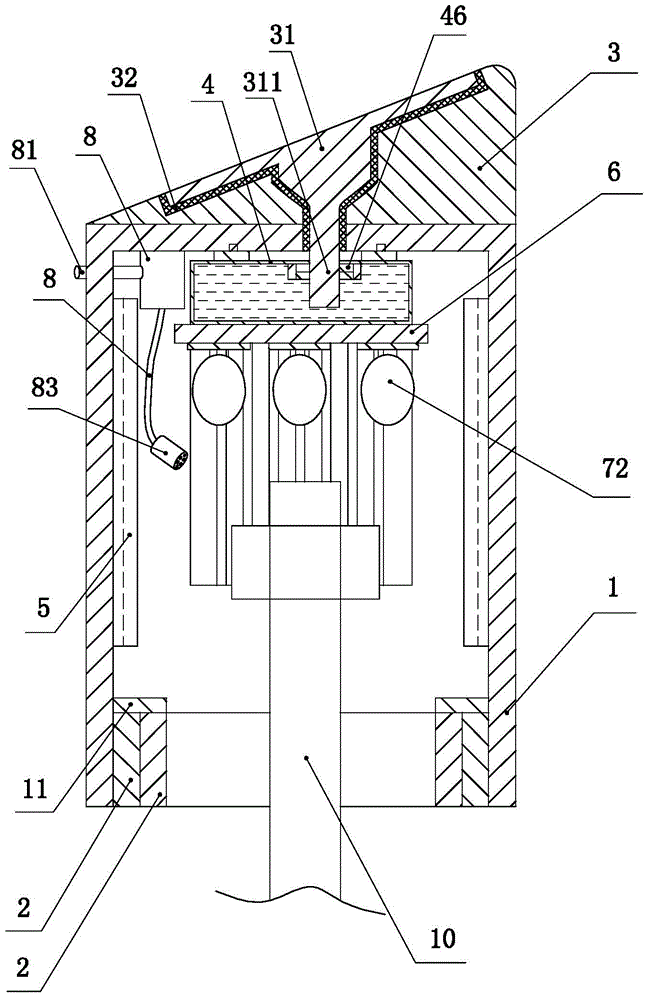

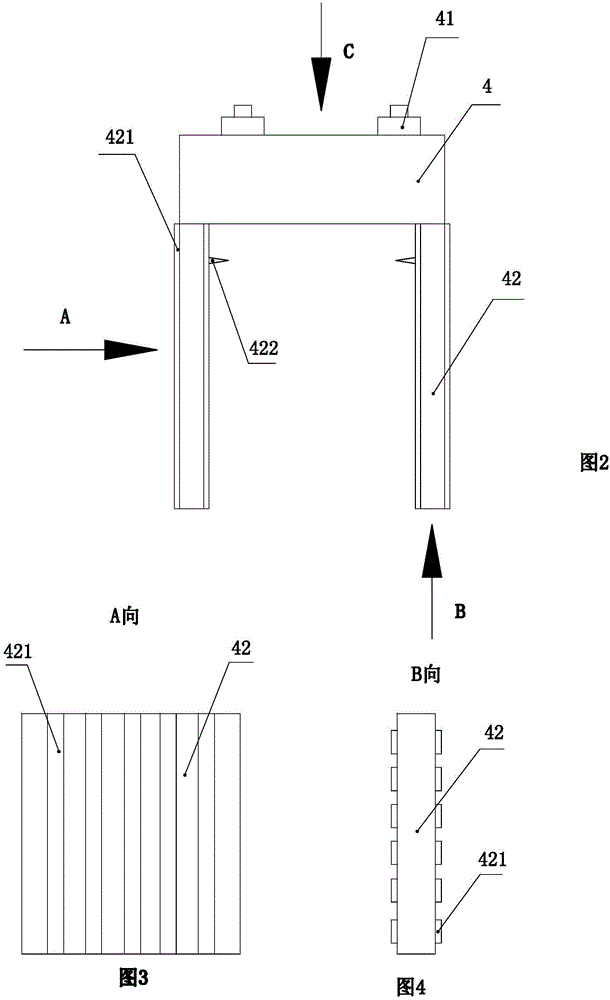

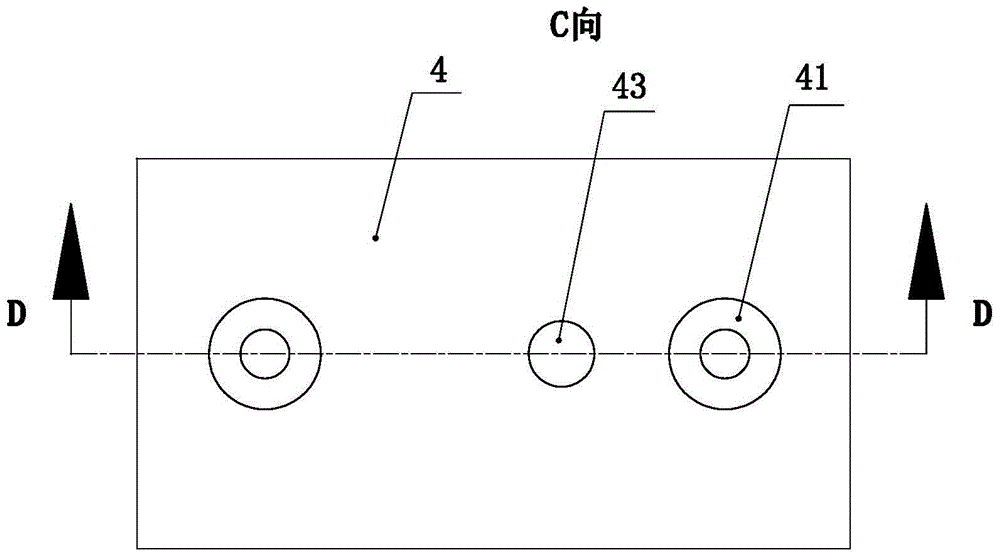

[0034] like Figure 1 to Figure 15 As shown, the present invention mainly includes cylinder body 1, mounting ring 2, end cap 3, first drying assembly, second drying assembly, spraying assembly and final protection assembly. The present invention will be described in detail below with reference to the accompanying drawings.

[0035] like figure 1 As shown, the cylinder body 1 is the main body of the present invention, and the cylinder body is a circular hollow plastic part, which can be made of PVC material. The lower end of the cylinder is open and the upper end of the cylinder is sealed. A mounting ring 2 is threaded on the inner wall of the lower end of the cylinder. The mounting ring is a circular plastic part. Threads are provided on the outer wall and the inner wall of the mounting ring. The threads on the outer wall of the mounting ring are used to cooperate with the inner wall of the cylinder. The threads on the inside wall of the mounting ring are used for mounting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com