LED (light emitting diode) lamp tube with replaceable electronic fluorescent lamp tube

A technology for LED lamps and fluorescent lamps, applied in the field of LED lamps, can solve problems such as large energy loss, and achieve the effect of reducing power consumption and reducing overall power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

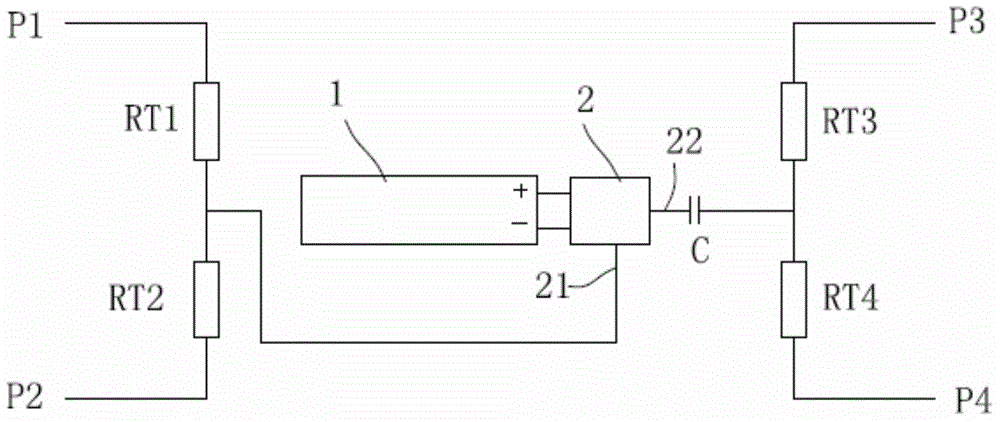

[0015] Such as figure 2 As shown, an LED light tube includes lamp pins P1, P2, P3, P4, LED lighting module 1 and power drive module 2, the LED light emitting module includes a substrate and LEDs fixed on it, and the power drive module 2 includes two output terminal, the first input terminal 21 and the second input terminal 22, and the two output terminals are respectively connected to the positive and negative poles of the LED lighting module 1. The power drive module 2 used in the present invention is a high-frequency power drive circuit, which mainly converts the high-frequency current output by the electronic ballast into direct current to supply the LED light-emitting module 1. It can use the LED drive circuit disclosed in CN203596948U.

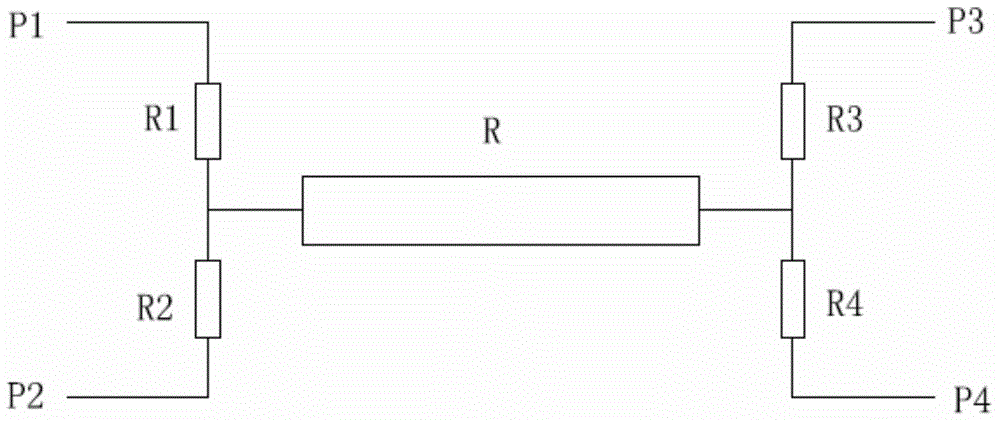

[0016] The LED lamp tube of the present invention is mainly used to replace traditional fluorescent lamp tubes with electronic ballasts. Since most of the existing electronic ballasts have a filament protection function, if the replaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com