An invisible snap-on baseboard heating system

A baseboard and buckle-type technology, which is applied in the field of invisible buckle-type baseboard heating systems, can solve the problems of affecting the use effect and appearance, increasing the difficulty of construction, and increasing the installation cost, so as to improve heat utilization efficiency, Effects that are easy to promote and use, and have low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

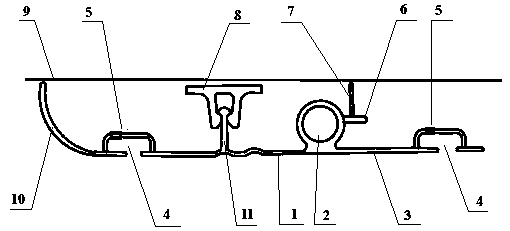

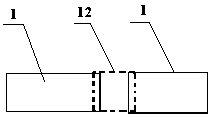

[0017] Such as figure 1 , figure 2 and image 3 As shown, an invisible snap-on skirting heating system is formed by connecting a plurality of skirting fins, and the skirting fins include a heat dissipation panel 1 and a pipe arranged inside the heat dissipation panel 1 2. The heat dissipation panels 1 are connected by buckling.

[0018] The heat dissipation panels 1 are connected by buckles, which overcomes many shortcomings of conventional rigid splicing: such as labor-intensive installation and construction, and thermal expansion and contraction may easily lead to gaps or even damage.

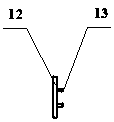

[0019] The buckle connection method of the present invention is specifically as follows: the heat dissipation panels 1 are connected by a shield 12, and the shield 12 is provided with one or more bumps 13, preferably two bumps, and the bumps 13 are connected to the said bumps. The card slots 4 on the heat dissipation panel 1 are locked tightly. The card slots 4 are respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com