Motor rotor and electric motor having it

A technology of motor rotor and rotor core, which is applied to synchronous motors, electrical components, and electromechanical devices with static armatures and rotating magnets, and can solve problems such as large torque ripple and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

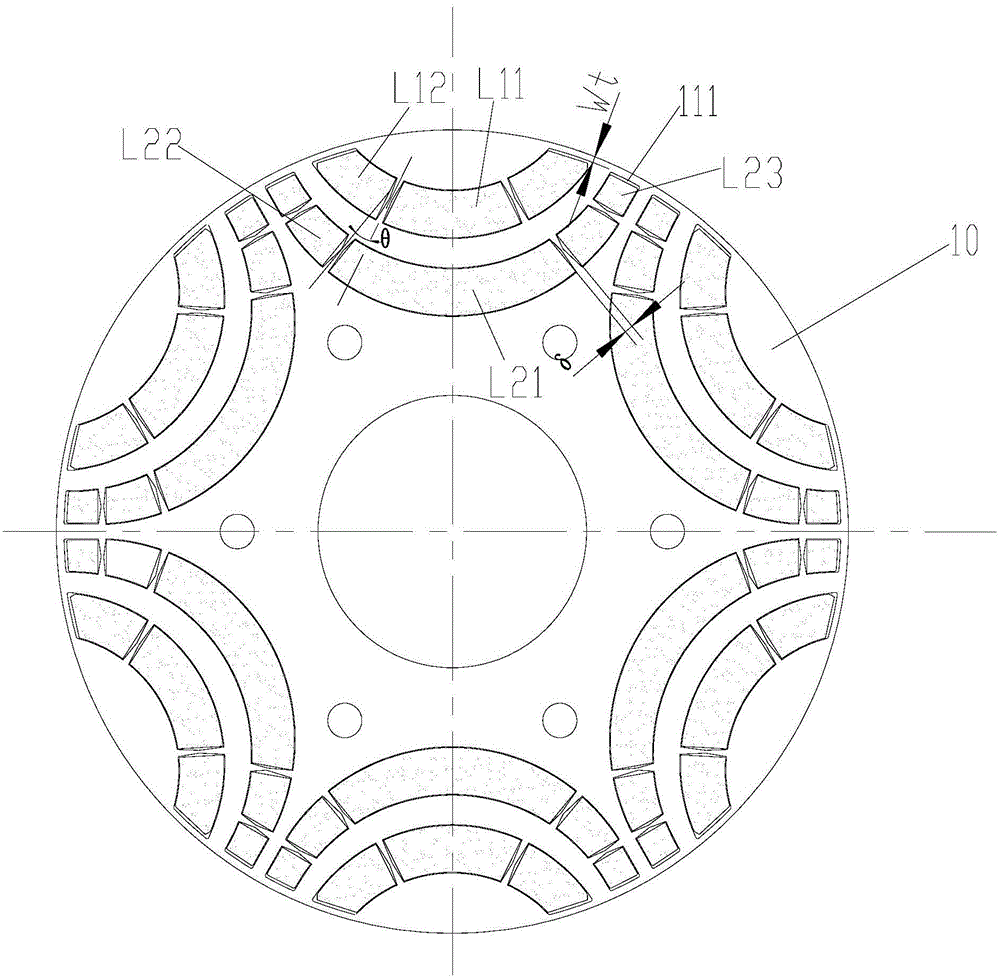

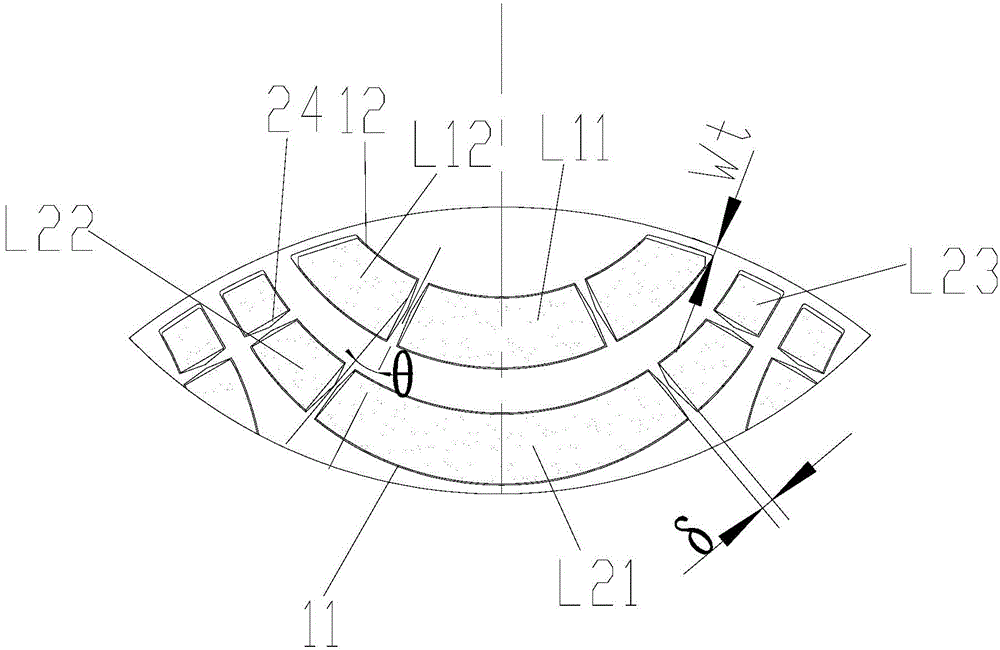

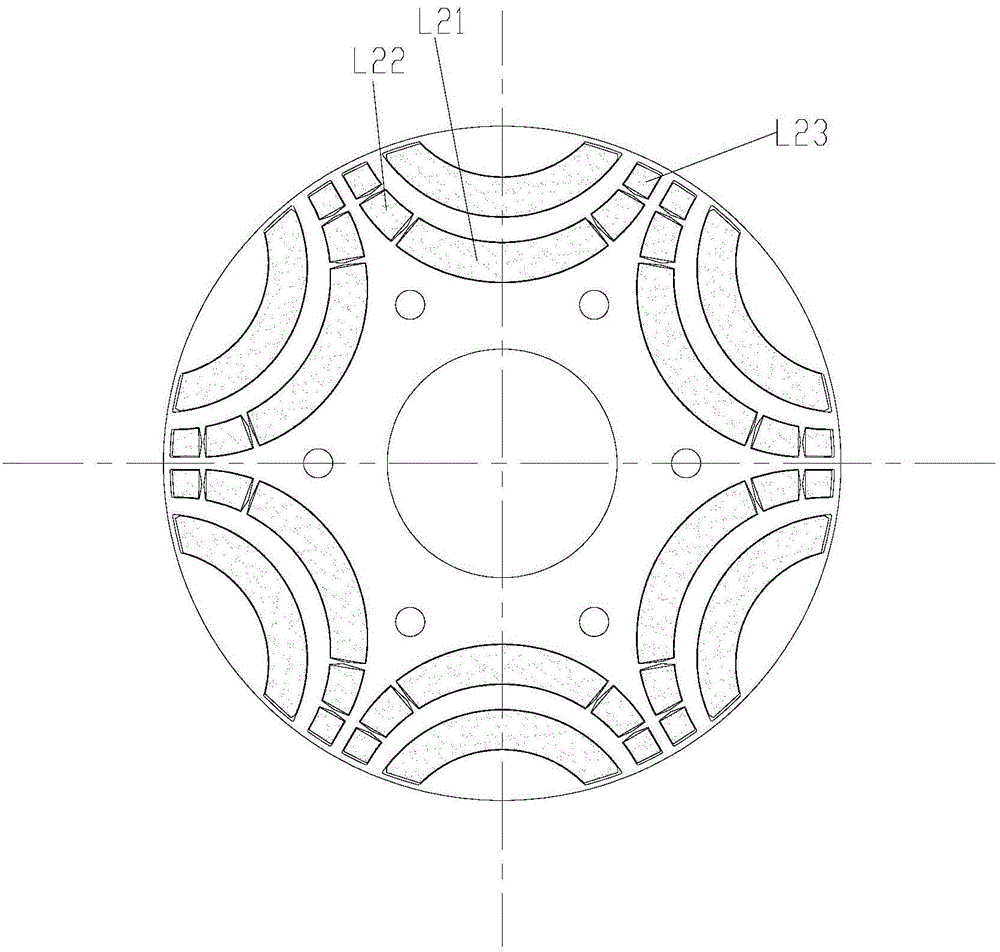

[0024] Such as Figures 1 to 6 As shown, according to the embodiment of the present invention, the motor rotor includes a rotor core 10, and the rotor core 10 is provided with a magnetic pole structure. The magnetic pole structure includes a multi-layer magnetic steel slot and a plurality of permanent magnet structures. There is a magnetic isolation bridge 111 at the end; the permanent magnetic structures are arranged in the magnetic steel grooves of each layer correspondingly, and the permanent magnetic structures in the magnetic steel grooves include a plurality of magnetic steels, and the multiple magnetic steels are divided into middle magnetic steel L11, L21 and an even number of side mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com