Direct-drive switch reluctance motor with teeth arranged at shaft end

A switched reluctance motor, direct drive technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as looseness, cable shedding, stringing, etc., to ensure service life, ensure accuracy, and solve corrosion problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

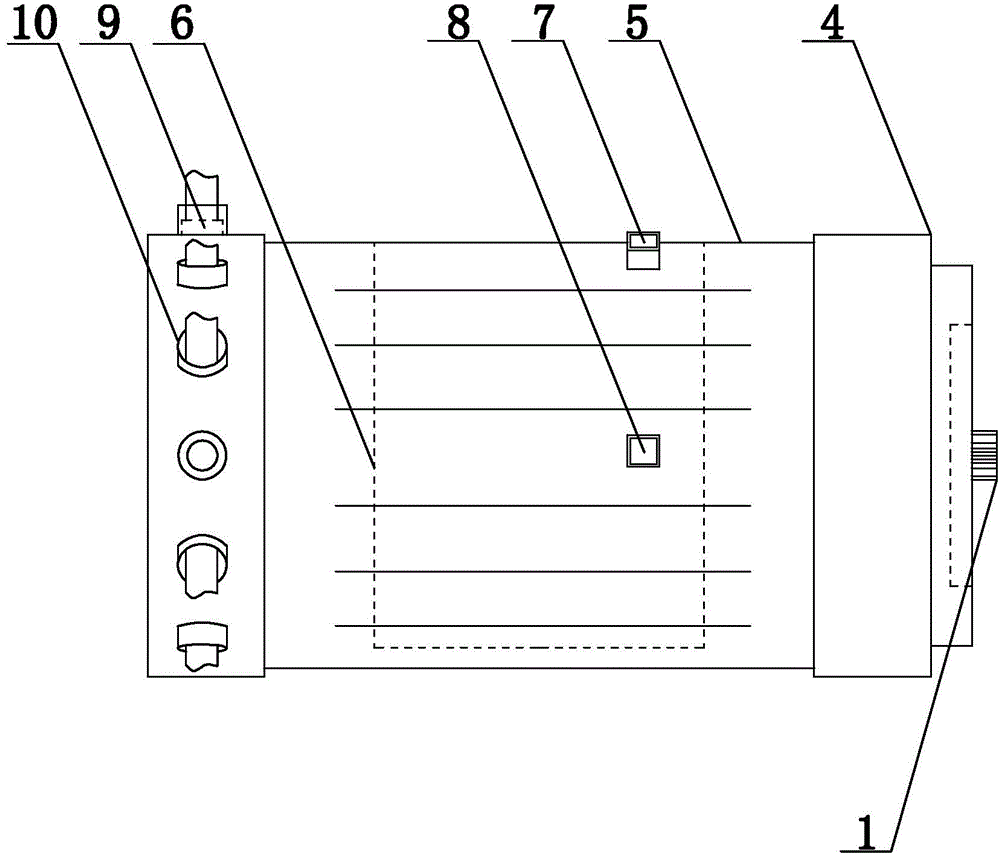

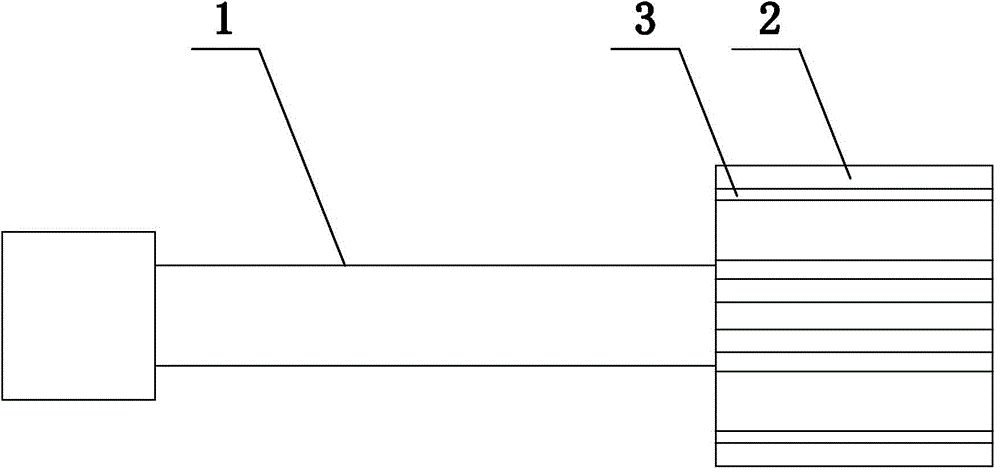

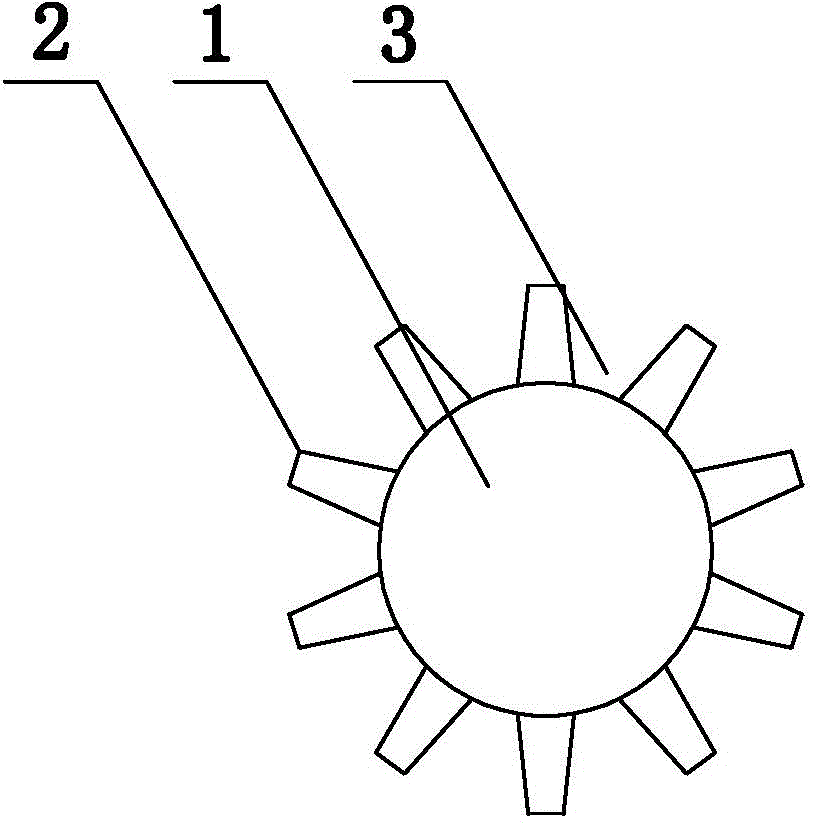

[0027] Embodiment 1: as figure 1 As shown, the shaft-end toothed direct drive switched reluctance motor of the present invention includes a switched reluctance motor 4, the switched reluctance motor 4 includes a rotating shaft 1, and an interlayer 6 is arranged in the shell 5 of the switched reluctance motor 4, and the shell 5 is provided with a water inlet 7 and a water outlet 8, and the interlayer 6 communicates with the outside world through the water inlet 7 and the water outlet 8. One end of the rotating shaft 1 is provided with a depression 2, and the depressions 2 are in a circular array based on the center of the cross-section of the rotating shaft 1. The protuberances between the two depressions 2 form teeth 3, and one side of the casing 5 of the switched reluctance motor 4 is provided with 6 connection ports 9, and the connection ports 9 are provided with threads, and are provided with a collar 10, and the collar 10 is set on the On the insulating skin of the cable, ...

Embodiment 2

[0028] Embodiment 2: On the basis of the structure described in Embodiment 1, the cross section of the depressions 2 is arc-shaped, and the shape and size of each depression 2 correspond to each other.

Embodiment 3

[0029] Embodiment 3: On the basis of the structure described in Embodiment 2, the teeth 3 are arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com