Preparation method for alpha-glucosidase inhibitor as well as product and usage thereof

A glucosidase and inhibitor technology, applied in the field of preparation of α-glucosidase inhibitors, can solve the problems of staying, lack of theoretical basis, hindering large-scale preparation and application of α-glucosidase inhibitors, etc. Effects of blood sugar fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

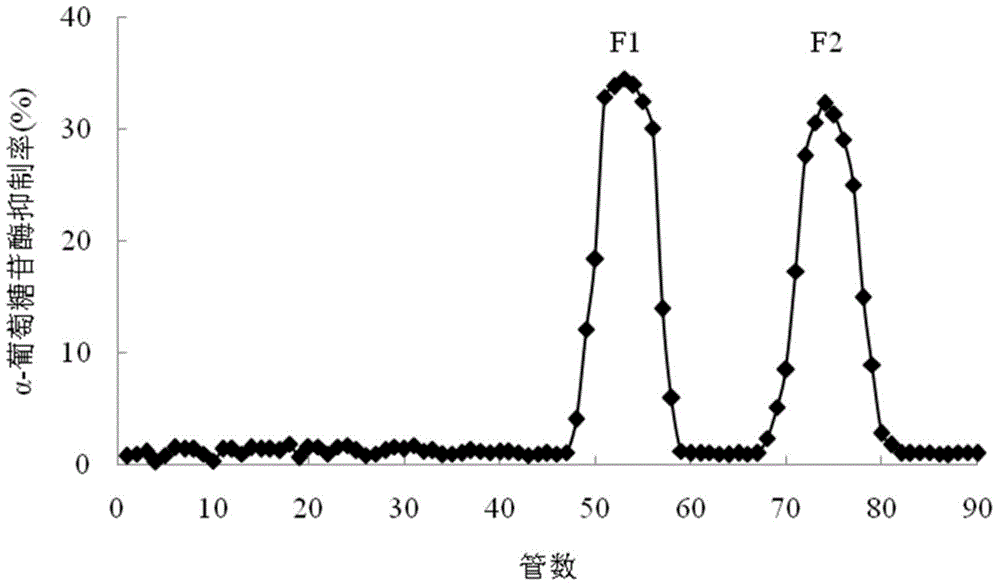

[0052] The preparation of embodiment 1 two kinds of α-glucosidase inhibitors

[0053] Use Lactobacillus plantarum ST-Ⅲ with the preservation number CGMCC No.0847 as the fermentation strain to ferment 1L of aseptic soybean milk at 25°C for 24 hours. The obtained fermentation liquid is heated at 100°C for 10 minutes, cooled to 25°C and centrifuged to obtain the supernatant , centrifuged at 8000rpm for 10 minutes to get the supernatant obtained by extraction with 2 times the volume of ethyl acetate, and after the obtained ethyl acetate phase was rotatably evaporated to dryness, 20mL of ethyl acetate was added to prepare the crude extract of α-glucosidase inhibitors. solution, take 1.5mL of the crude extract and put it on the silica gel column whose initial condition is ethyl acetate: n-hexane volume ratio of 2:3 (v / v), according to the volume ratio of ethyl acetate: n-hexane : 3 (v / v), the volume ratio of ethyl acetate:n-hexane is 3:2 (v / v), the volume ratio of ethyl acetate:n-he...

Embodiment 2

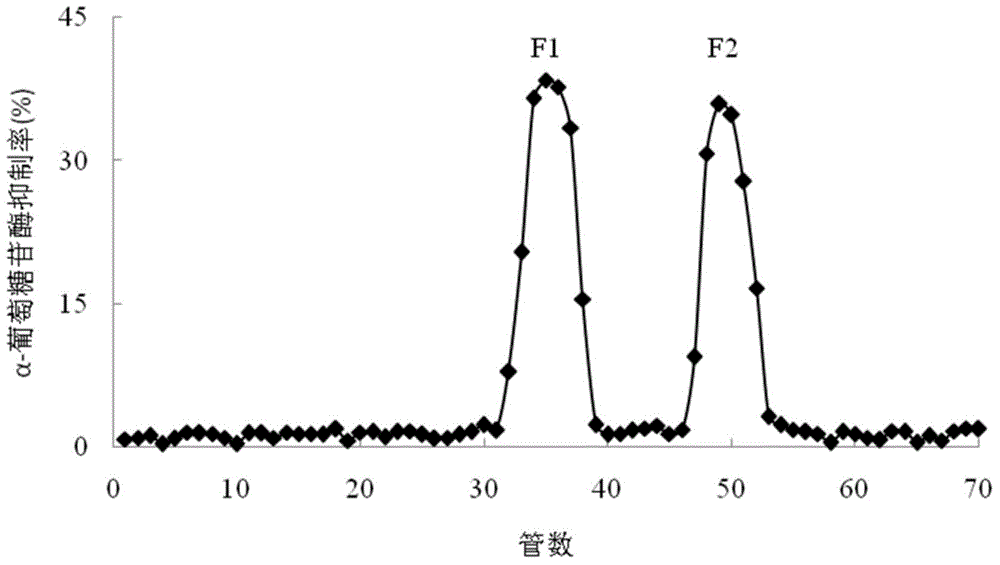

[0055] The preparation of embodiment 2 two kinds of α-glucosidase inhibitors

[0056] Use Lactobacillus plantarum ST-Ⅲ with the preservation number CGMCC No.0847 as the fermentation strain to ferment 1L of aseptic soybean milk at 40°C for 120 hours. The obtained fermentation liquid is heated at 98°C for 20 minutes, cooled to 20°C and then centrifuged at 9000rpm for 15 minutes. Get supernatant, the supernatant of gained uses the ethyl acetate of 4 times volume to extract, after the ethyl acetate phase of gained is evaporated to dryness, add 20mL ethyl acetate and be mixed with the crude extract of α-glucosidase inhibitor, take this 1.5 mL of the crude extract was loaded on a silica gel column whose initial condition was ethyl acetate: n-hexane volume ratio of 2:3 (v / v), according to the ethyl acetate: n-hexane volume ratio of 2:3 (v / v), ethyl acetate: the volume ratio of n-hexane is 3:2 (v / v), ethyl acetate: the volume ratio of n-hexane is 4:1 (v / v) order, with the flow rate o...

Embodiment 3

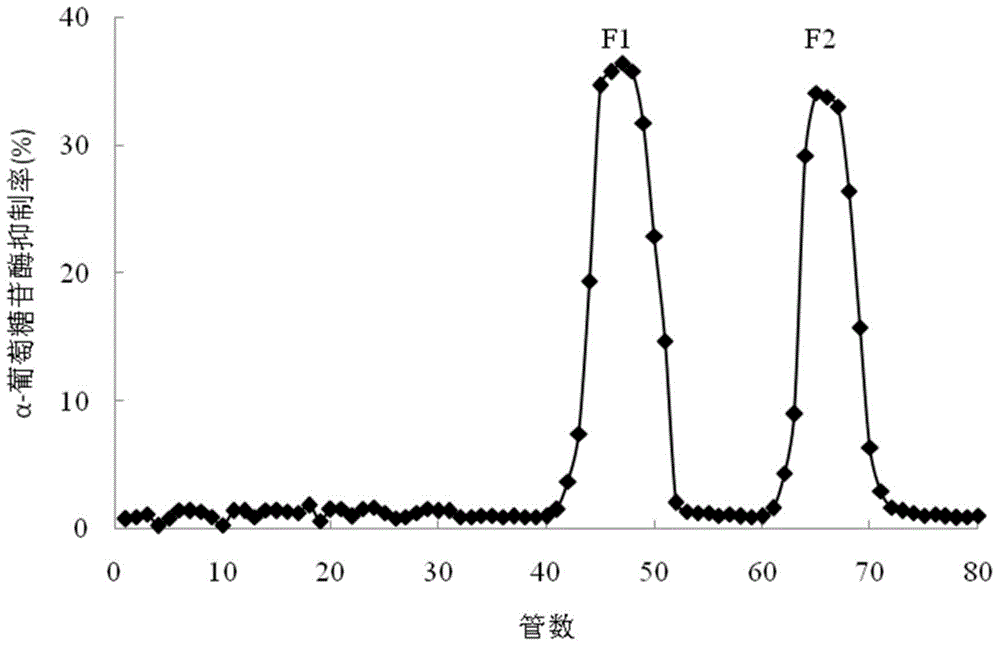

[0058] The preparation of embodiment 3 two kinds of α-glucosidase inhibitors

[0059] Use Lactobacillus plantarum ST-Ⅲ with preservation number CGMCC No.0847 as the fermentation strain to ferment 1L of aseptic soybean milk at 37°C for 72 hours, heat the obtained fermentation liquid at 95°C for 30min, cool to 15°C and centrifuge at 8000rpm for 10 minutes Get supernatant, the supernatant of gained uses the ethyl acetate of 5 times of volumes to extract, and after the ethyl acetate phase of gained is rotary evaporated to dryness, add 20mL ethyl acetate and be mixed with the crude extract of α-glucosidase inhibitor, take this 1.5 mL of the crude extract was loaded on a silica gel column whose initial condition was ethyl acetate: n-hexane volume ratio of 2:3 (v / v), according to the ethyl acetate: n-hexane volume ratio of 2:3 (v / v), the volume ratio of ethyl acetate: n-hexane is 3:2 (v / v), the volume ratio of ethyl acetate: n-hexane is 4:1 (v / v) sequence, with a flow rate of 1.5mL / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com