Method for manufacturing slipper vamps in ultrasonic integrated hot-pressing forming mode

A production method and ultrasonic technology, which are applied to shoe-making machinery, footwear, and adhesive shoe parts, etc., can solve the problems of inaccurate positioning between fabrics, deformation of the upper surface of the slipper, and separation of various layers of fabrics, so as to improve the use of Life and appearance, improve processing efficiency and quality, and improve the surface quality of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

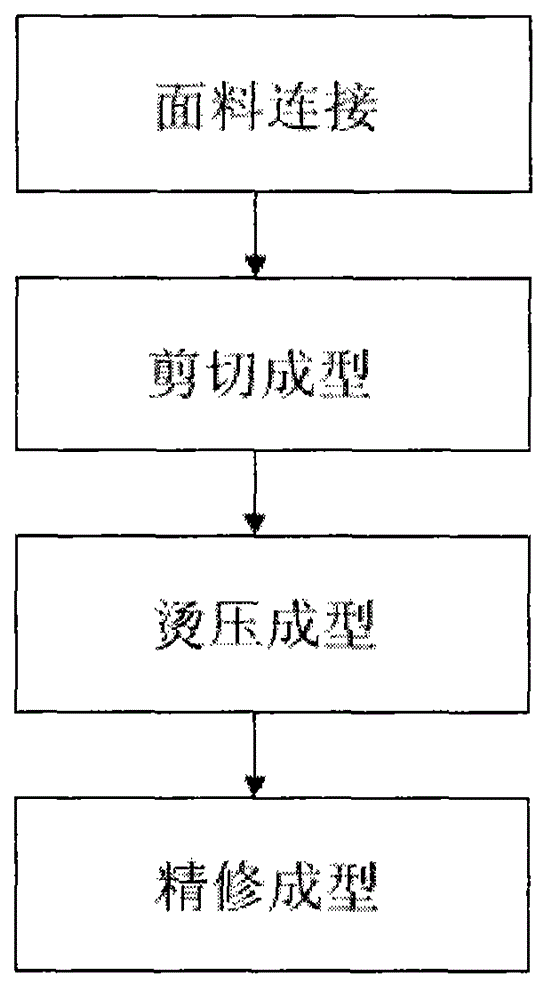

[0019] The first step is fabric connection. According to the needs of processing slippers, select coral fleece, nylon cloth, pearl cotton and other skin materials and sponge and other upper fabrics, and layer these fabrics in order to arrange them neatly, and wrap the sponge on the skin. The inside of the material, and use the adhesive to bond the various fabrics to form a unified overall multi-layer structure blank, and let it dry naturally.

[0020] In the second step, shear forming, the dried blank is cut according to the shape and structure of the slippers upper mold, and the size of the cut fabric blank is 1 cm larger than the size of the slippers upper mold.

[0021] The third step is hot pressing forming. The sheared and formed fabric blank is hot pressed and formed according to the production requirements of the ultrasonic hot pressing equipment. The temperature of the hot pressing of the fabric blank is 100°C, the hot pressing pressure is 100N, and the hot pressing tim...

Embodiment 2

[0024] A method for using a high-efficiency cooling heat dissipation device includes the following steps:

[0025] A method for manufacturing an upper surface of slippers formed by ultrasonic integrated hot pressing, comprising the following steps:

[0026] The first step is fabric connection. According to the needs of processing slippers, select genuine fabrics, waffles, velvet, pearl cotton and other skin materials and sponges and other upper fabrics, and layer these fabrics in order and arrange them neatly, and cover them with sponges In the interior of the skin material, the various fabrics are bonded with an adhesive to form a unified overall multi-layer structure blank, which is allowed to dry naturally.

[0027] In the second step, shear forming, the dried blank is cut according to the shape and structure of the slippers upper mold, and the size of the cut fabric blank is 1.5 cm larger than that of the slippers upper mold.

[0028] The third step is hot pressing formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com