Method for preparing novel one-bath-multicolor batik silk fabric

A silk and fabric technology, applied in dyeing, bleaching products, textiles and papermaking, etc., can solve problems such as complexity, lack of color in fabrics, monotonous process, etc., achieve brilliant colors, brilliant colors, ensure clarity and dyeing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

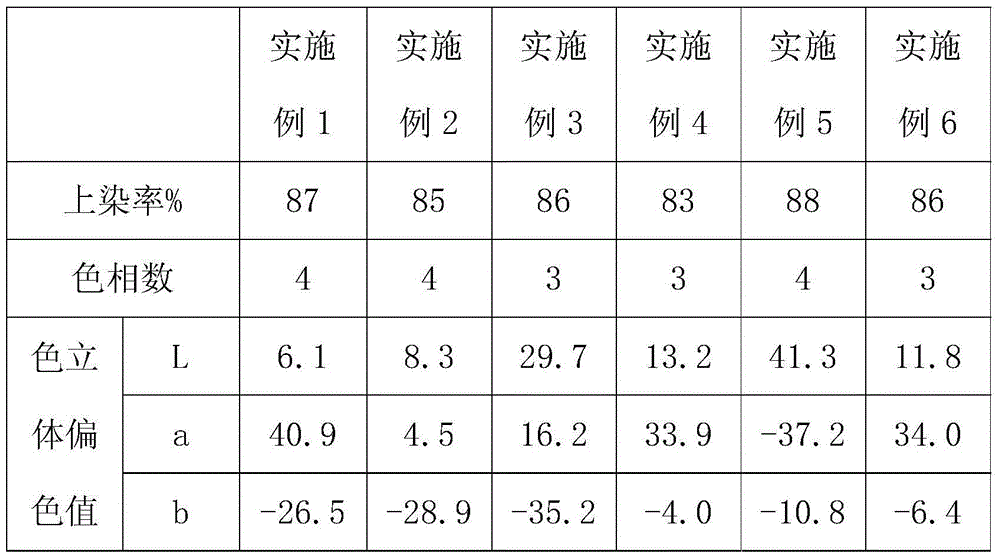

Embodiment 1

[0027] After the burrs, impurities and stains are removed from the mulberry silk fabric, the refining and bleaching treatment is carried out to obtain the pretreated silk fabric. Immerse the local pattern area of the pretreated silk fabric into the natural dye of chitosan and red vegetable dye with a total mass fraction of 30%, soak for 10min at 60°C, wash and dry to obtain the predyed silk fabric, and then dye and undye it. The area to be dyed is sealed with paraffin wax, and dried at 75°C to obtain a waxed silk fabric.

[0028] Dip the waxed silk fabric in the mixed dye of green acid dye and blue reactive dye with a mass ratio of 2:3, bath ratio 1:40, at 45°C, 20kHz ultrasonic treatment for 12min, take it out, and steam dewax , washed 3 times, and dried at 60°C to obtain a bath of colorful batik silk fabrics.

Embodiment 2

[0030] After removing burrs, impurities and stains from the tussah silk fabric, it is refined and bleached to obtain a pretreated silk fabric. Immerse the local pattern area of the pretreated silk fabric into the natural dye of chitosan and red vegetable dye with a total mass fraction of 35%, soak for 10min at 65°C, wash and dry to obtain the predyed silk fabric, and then dye and undye it. The area to be dyed is sealed with paraffin wax, and dried at 75°C to obtain a waxed silk fabric.

[0031] Dip the waxed silk fabric in the mixed dye of green acid dye and blue reactive dye with a mass ratio of 2:3, bath ratio 1:40, at 48°C, 13kHz ultrasonic treatment for 13min, take it out, and steam dewax , washed 3 times, and dried at 60°C to obtain a bath of colorful batik silk fabrics.

Embodiment 3

[0033] After removing burrs, impurities and stains from the regenerated silk protein silk fabric, it is refined and bleached to obtain a pretreated silk fabric. Immerse the local pattern area of the pretreated silk fabric into the natural dye of chitosan and red vegetable dye with a total mass fraction of 32%, soak for 10min at 64°C, wash and dry to obtain the predyed silk fabric, and then dye and undye it. The area to be dyed is sealed with paraffin wax, and dried at 78°C to obtain a waxed silk fabric.

[0034] Dip the waxed silk fabric in the mixed dye of green acid dye and blue reactive dye with a mass ratio of 2:3, bath ratio 1:40, at 47°C, 18kHz ultrasonic treatment for 14min, take it out, and steam dewax , washed 3 times, and dried at 60°C to obtain a bath of colorful batik silk fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com