High-speed and heavy-load track fixing system

A fixing system and track technology, applied in the direction of tracks, fixed rails, railway fixing devices, etc., can solve the problems of damage to the rail fittings and track foundation, shorten the service life of the overall rail, and the lateral displacement cannot be released, etc., and achieve resonance. And stress relief and reduction, good vibration and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The application will be further explained below in conjunction with the accompanying drawings.

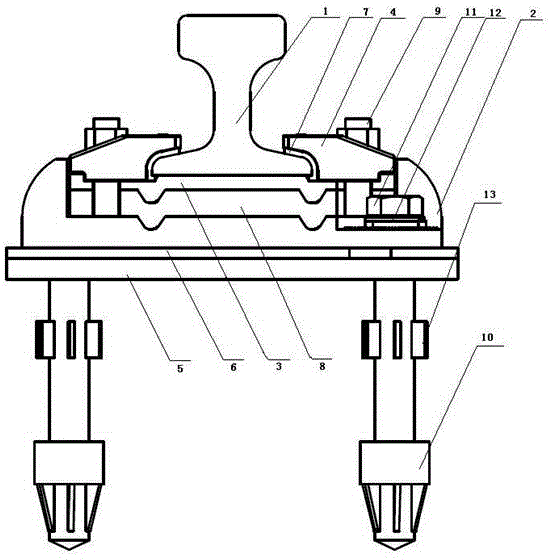

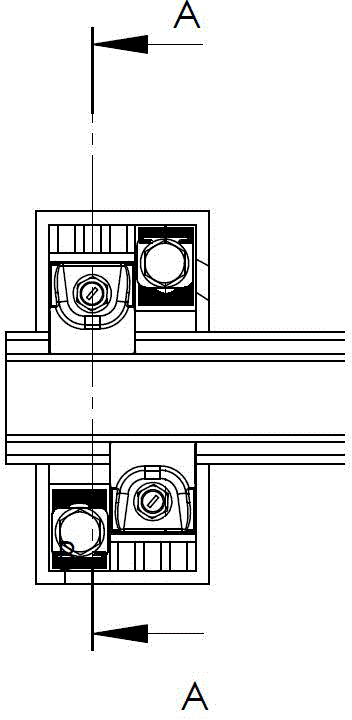

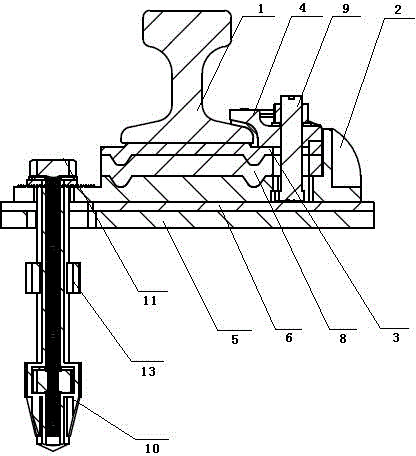

[0024] Such as figure 1 As shown, the high-speed heavy-duty rail fixing system provided by the present application includes a rail 1, and the system also includes a base 2, a rail bottom rubber backing plate 3, a PE backing plate 5 and a PE backing plate 6, an upper pressure plate 4, T-shaped bolts 9, Anchor system, adjusting backing plate 8 and other components, the upper pressure plate 4 is fixed on the base 2 through T-shaped bolts 9, the bolts are automatically locked and positioned after being tightened, and the vulcanized rubber pressure surface of the upper pressure plate is pressed against the rail, and the rail and the upper The lower part of the pressure plate is installed with a rubber rail bottom backing plate 3. The lower part of the rail bottom backing plate 3 can be added with an adjustment backing plate 8 according to the actual needs of the installation. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com