Splash-proof labor-saving drilling fluid screening device

A screening device, labor-saving technology, applied in the direction of filtration and separation, flushing wellbore, earthwork drilling and mining, etc., can solve the problems of high energy consumption, low screening efficiency, inconvenient operation of filtration equipment, etc., to achieve improved filtration efficiency and convenience Replacement and cleaning, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

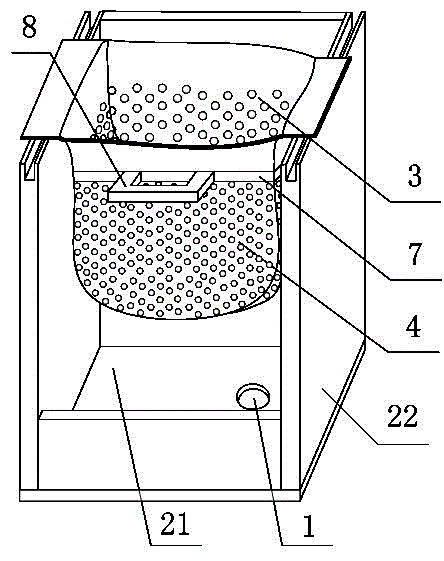

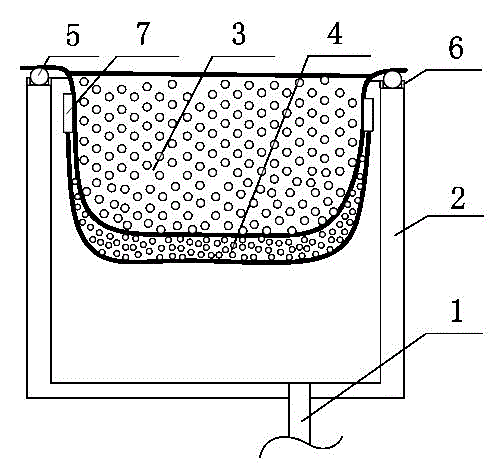

[0031] Splash-proof and labor-saving drilling fluid screening device, such as figure 1 , figure 2 and image 3 As shown, it includes a filter cylinder 2 with a discharge port 1 at the bottom, and an upper screen 3 and a lower screen 4 arranged in the filter cylinder 2, and is characterized in that:

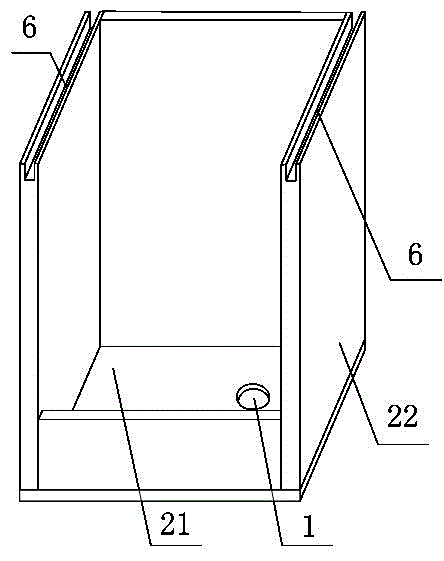

[0032] Described filter cylinder body 2 comprises base plate 21, and the bottom end is fixed on three support plates 22 on base plate 21; One of the cuboid structures with side walls open;

[0033] The longitudinal section of the upper screen 3 is "U"-shaped, and rollers 5 are arranged on both sides of the top, and the tops of the two supporting plates 22 parallel to each other are provided with slideways 6 that cooperate with the rollers 4; The subnet 4 is fixed on the bottom end of the upper screen 3 through the connecting rod 7, and the connecting rod 7 is provided with a push-pull handle 8.

[0034] In order to facilitate the sieved drilling fluid to effectively flow out ...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that a power device is also connected to the connecting rod 7 in this embodiment.

[0037] In this embodiment, the power device is a linear stepper motor.

Embodiment 3

[0039] The difference between this embodiment and Embodiment 3 is that the power device in this embodiment is preferably a linear moving cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com