Adjustable double-pulse solid rocket engine jet pipe testing device

An engine nozzle, solid rocket technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of damage to the data signal line of the thrust sensor, uneconomical, etc., to save the test cost, simple structure, parts less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

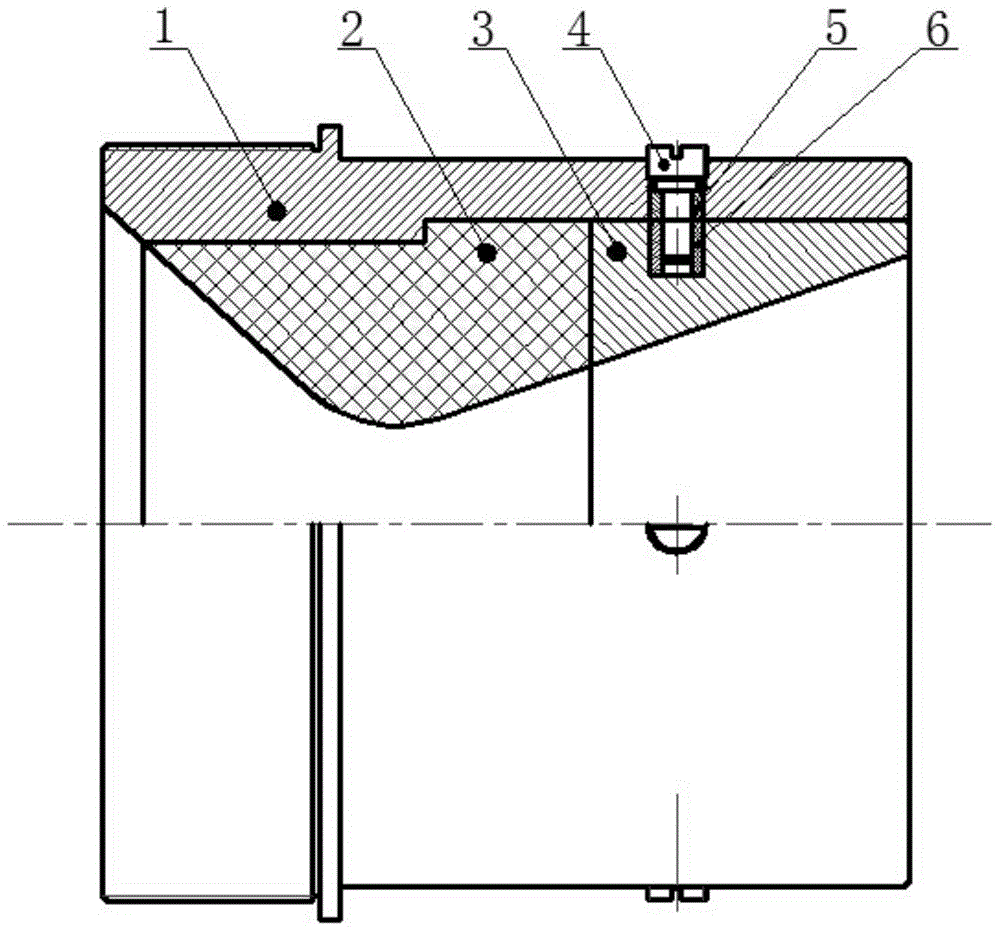

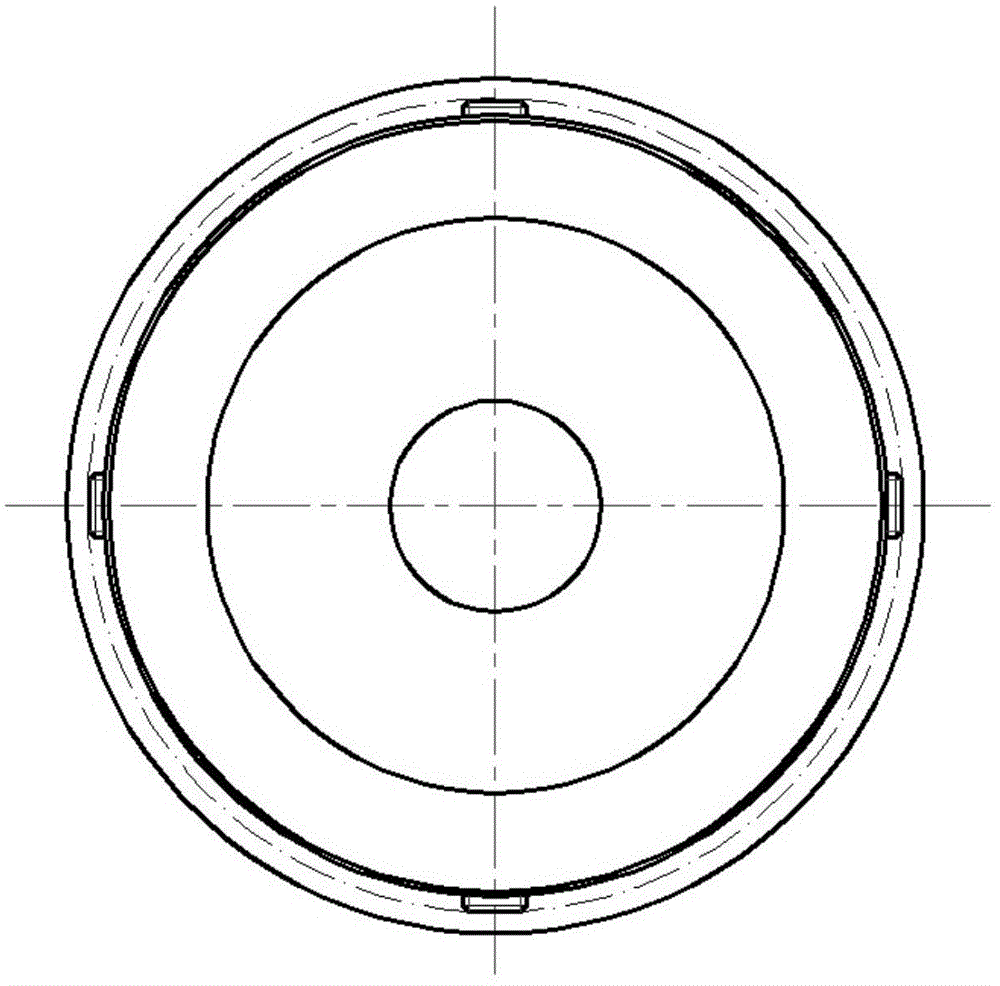

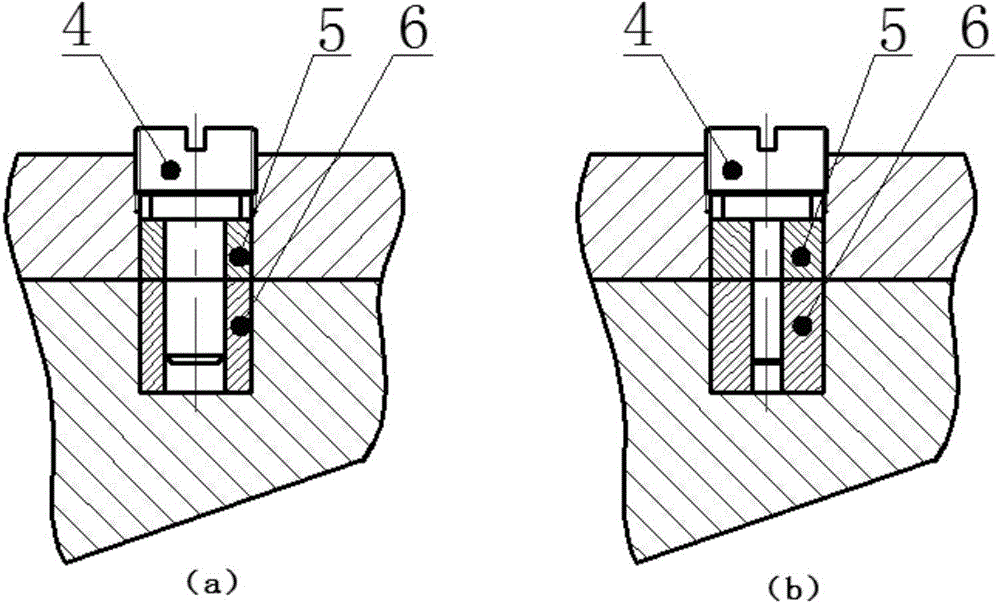

[0016] combine Figure 1 ~ Figure 3 :

[0017] An adjustable double-pulse solid rocket motor nozzle test device of the present invention comprises a nozzle seat 1, a throat liner 2, an expansion section part 3, a safety pin 4, an upper shear sleeve 5 and a lower shear sleeve 6, The throat liner 2 is set at the gas inlet end of the nozzle seat 1, and the expansion section part 3 is set at the gas outlet end of the nozzle seat 1. The throat liner 2 is connected to the nozzle seat 1 through its axial annular step surface The inner annular step surface is positioned and matched, the safety pin 4 passes through the pin hole on the wall of the nozzle seat 1 and extends into the pin hole on the expansion section part 3, and an upper shear sleeve is arranged between the safety pin 4 and the nozzle seat 1 5. A lower shearing sleeve 6 is set between the safety pin 4 and the expansion section part 3, and the safety pin 4 and the end of the pin hole of the nozzle holder 1 close to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com