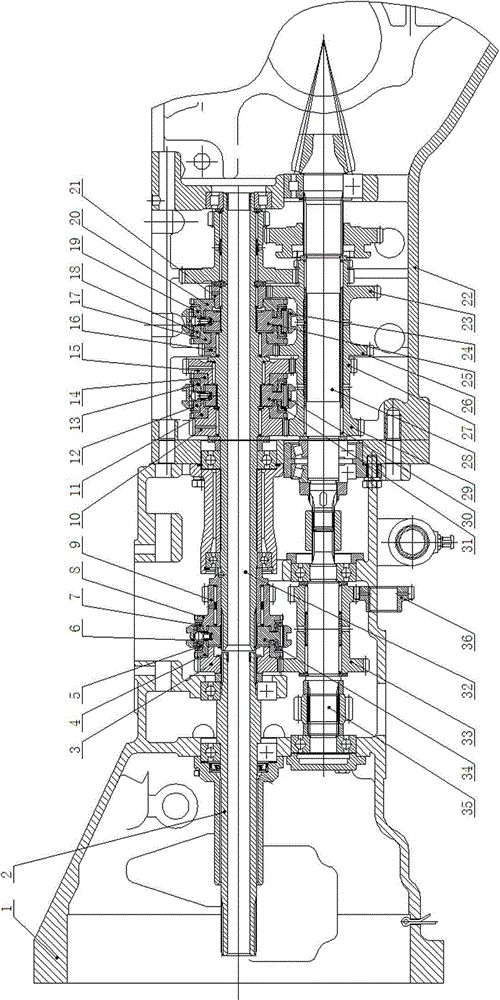

Synchronizer gear shifting device of shuttle-type gearbox of tractor of 25-40 horsepower

A technology of shifting device and synchronizer, which is applied to the transmission device, transmission device parts, gear transmission device, etc., which can solve the problems of higher and higher requirements for operating comfort, fatigue of the driver, and influence on the normal operation of the tractor. Achieve the effect of comfortable and convenient operation, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The gearbox synchronizer shifting device includes a front housing 1 and a rear housing 22 which are sealed and connected front and rear by bolts, and the driving shaft 2 of the shuttle gear, the intermediate shaft 35 of the shuttle gear, the first shaft 32, the second shaft 28, and the shuttle gear. The gear driving shaft 2 and the shuttle gear intermediate shaft 35 are installed in the front housing 1, and the first shaft 32 and the second shaft 28 are installed in the rear housing 22. The axes of the shuttle gear driving shaft 2 and the first shaft 32 are on the same plane. On the straight line, the axes of the shuttle gear intermediate shaft 35 and the two shafts 28 are on the same straight line; the shuttle gear driving shaft 2 is equipped with the shuttle gear driving gear 3 and the shuttle gear passive gear 9; the shuttle gear intermediate shaft On the 35, a shuttle block driven gear 33 is installed, and the shuttle block driven gear 33 meshes with the shuttle bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com