Zinc sulfide drying device used for optical infrared imaging

A technology of infrared imaging and drying equipment, which is applied in the direction of drying, drying machine, heating equipment, etc., can solve the problems of inconsistent drying effect of zinc sulfide, non-continuous zinc sulfide, poor drying effect, etc., and reach the drying degree Consistent, even heating, and push-and-go results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific examples.

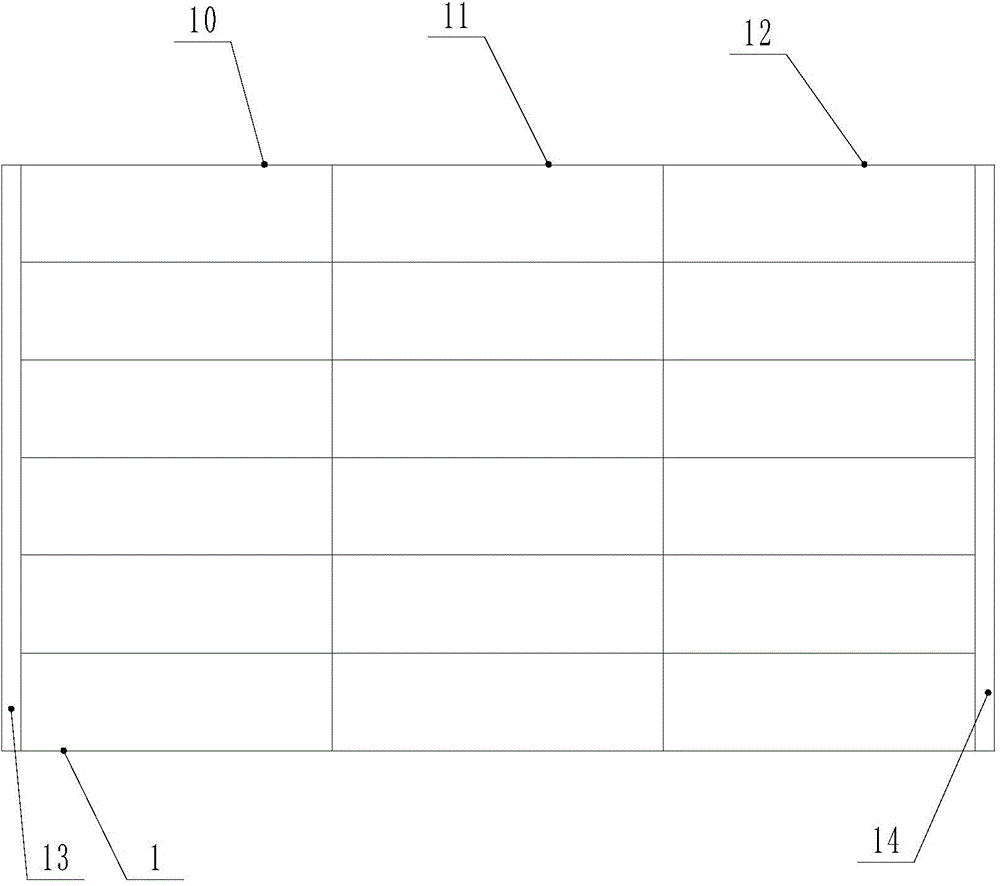

[0020] The front, back, left, and right described in the present invention are determined by the observer facing the front door 13, that is, the observer faces figure 1 OK on paper.

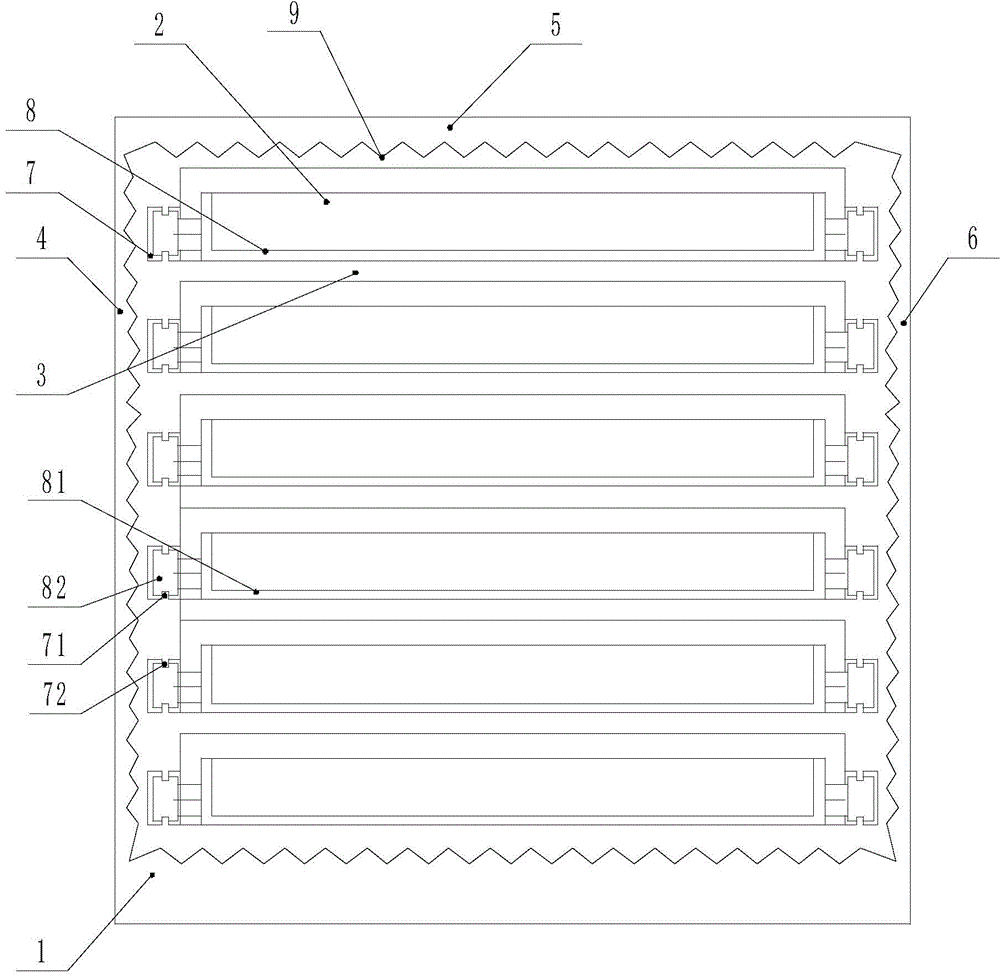

[0021] Such as figure 1 , 2 As shown, a zinc sulfide drying device for optical infrared imaging includes a box body 1, an electric heating device, and a drawer 8 for containing zinc sulfide. The box body 1 is a rectangular parallelepiped box body 1, and the box body 1 includes a left Side plate 4, right side plate 6, top plate 5, bottom plate and front door 13 and back door 14, described electric heating device is arranged on the box body 1, and described electric heating device comprises electric heating pipe 9, and this electric heating pipe 9 is arranged on On the left side plate 4, the right side plate 6 and the top plate 5, the heating pipes are also arranged on the bottom, so that heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com